Method for preventing plasma display from hole-filling by fluorescent powder printing

A plasma and display technology, which is applied in the manufacture of non-luminescent electrodes, the manufacture of discharge tubes/lamps, electrical components, etc., can solve problems such as clogging, and achieve the effect of high luminous efficiency and smooth surface

Inactive Publication Date: 2008-10-22

NANJING HUAXIAN HIGH TECH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem that the small holes are easily blocked when the phosphor layer of the shadow mask type PDP is prepared, and to invent a method for preventing the phosphor powder printing from blocking the plasma display. On the inner wall of the mask mesh, and ensure that the small holes of the shadow mask will not be blocked

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

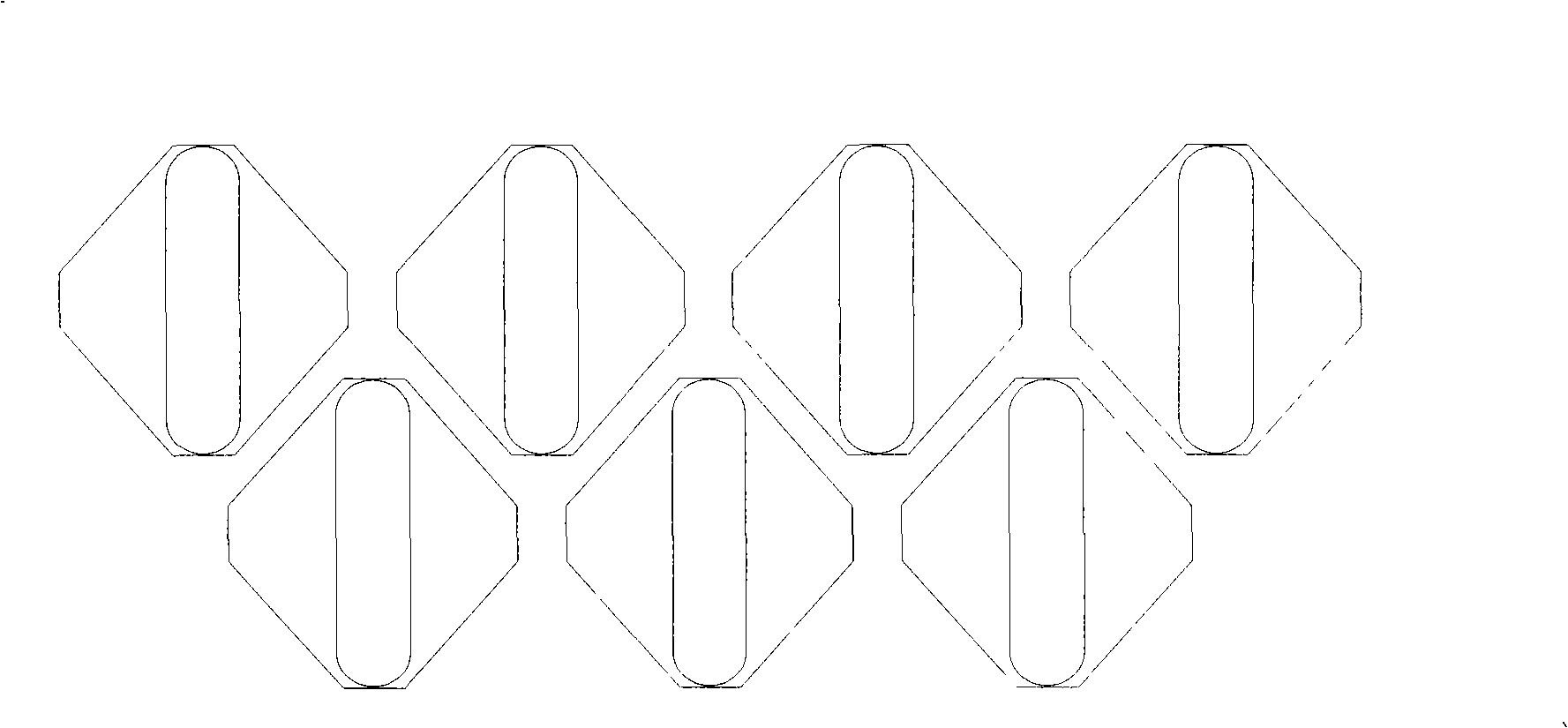

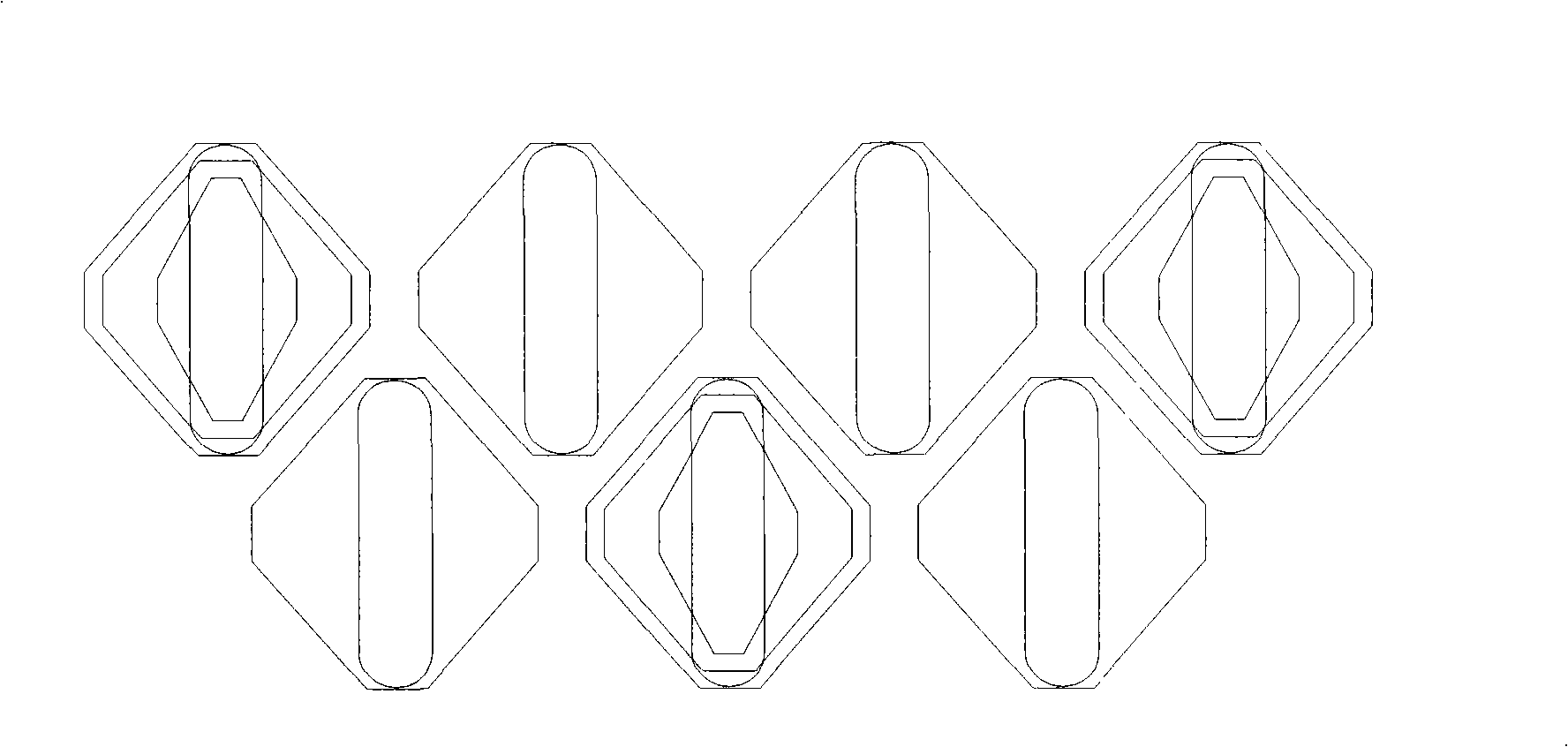

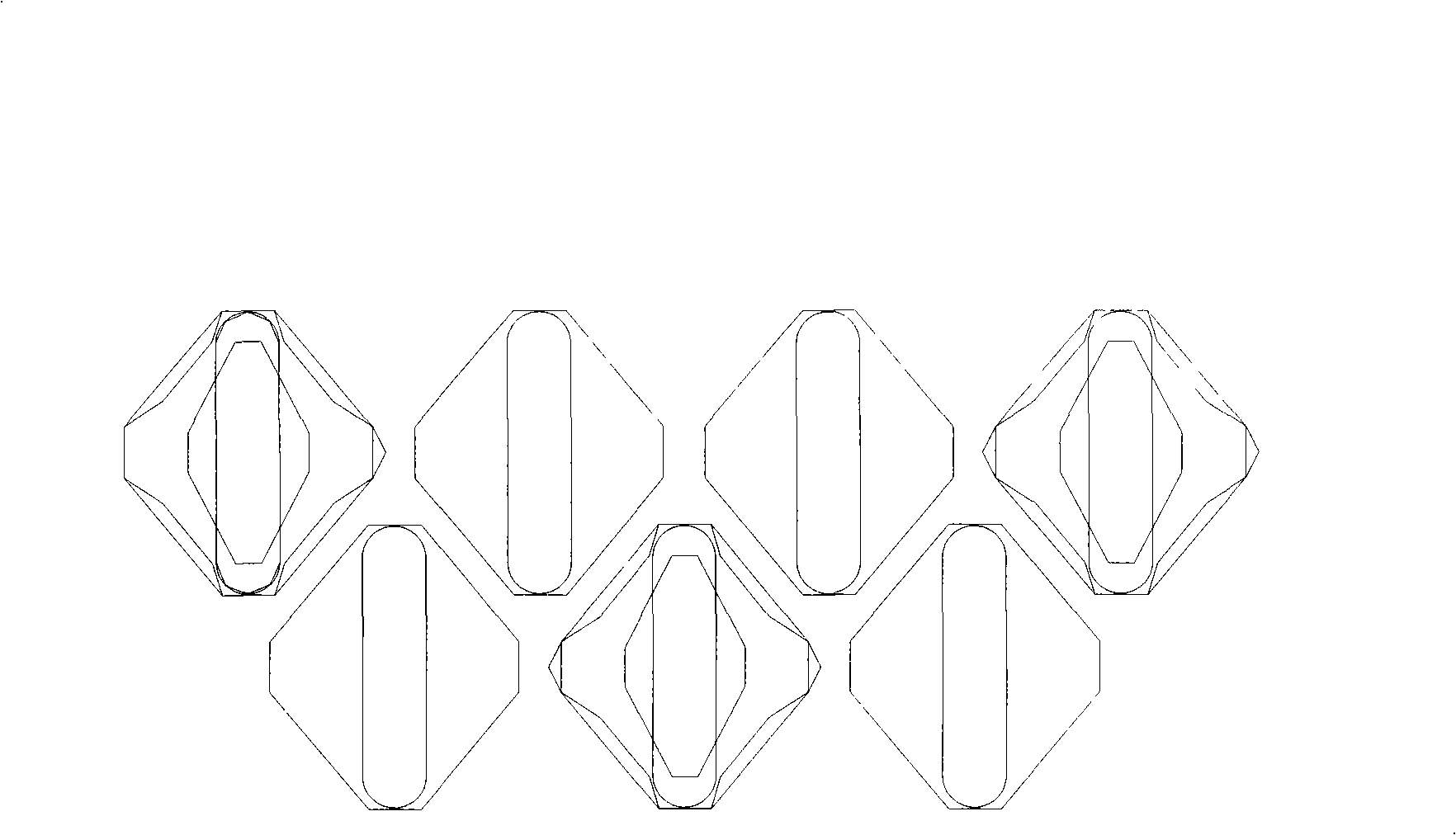

The invention discloses a method for preventing printing hole blocking of fluorescent powder used for a plasma display, which belongs to the flat television technical field. The method is characterized in that: firstly, pattern arrangements corresponding to printing screens are preset according to the arrangement condition of shadow mask holes on a printing shadow mask to ensure that the quantity of patterns on each-color screen is equal to one third of the quantity of all the holes on the shadow mask; secondly, the patterns on each-color screen are designed into ring-shaped patterns, the dimension and the shape of which are matched with those of the shadow mask holes. The method has the advantages of simplicity and feasibility, successfully solves printing and shaping problems of fluorescent powder paste in a shadow mask type PDP, and has no color mixing and hole blocking after the printing; and a fluorescent powder layer is even and compact, and has smooth surface and high luminous efficiency.

Description

Method for Preventing Plasma Displays from Clogging Holes by Phosphor Powder Printing technical field The invention relates to a plasma display technology, in particular to a method for printing fluorescent powder for a plasma display, in particular to a method for preventing holes from being printed with fluorescent powder for a plasma display. Background technique At present, SMPDP is a new type of shadow mask type opposite discharge PDP. In its structure, the shadow mask is used to replace the barrier ribs in traditional PDP production, which saves the complicated process of making tall and narrow barrier ribs on the rear substrate, and at the same time makes the entire screen process into a combination of three independent parts; the shadow mask is a CRT It is a mature accessory in the manufacture of color picture tubes. Using the shadow mask as a barrier in this way improves the yield of the whole screen and reduces the cost. Among them, the shadow mask is made of pu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J9/227H01J9/14

Inventor 刘凯樊兆雯朱立锋王保平张雄林青园戴慧

Owner NANJING HUAXIAN HIGH TECH CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com