Polarizing plate, optical film and image display

A technology of polarizers and films, applied in optics, optical elements, polarizing elements, etc., can solve the problems of unsatisfactory durability, large dimensional changes, and dimensional changes, and achieve good dimensional stability, high durability, and good adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167] (Adhesive: curable component)

[0168] As an adhesive, N-acryloylmorpholine was used.

[0169] (production of polarizer)

[0170] On one side of the above-mentioned transparent protective film, the above-mentioned adhesive was coated with a microgravure coating agent (gravure roll: #180, rotation speed 140% / line speed) to a thickness of 5 μm to obtain an adhesive-attached transparent protective film. Next, the above-mentioned transparent protective film with an adhesive was bonded to both surfaces of the above-mentioned polarizer using a roll mill. Electron beams were irradiated from the bonded transparent protective film side (both sides) to obtain a polarizing plate having a transparent protective film on both sides of the polarizer. The linear velocity is 20m / min, the accelerating voltage is 250kV, and the irradiation dose is 20kGy. The Tg was 140°C, and the gel percentage was 72% by weight.

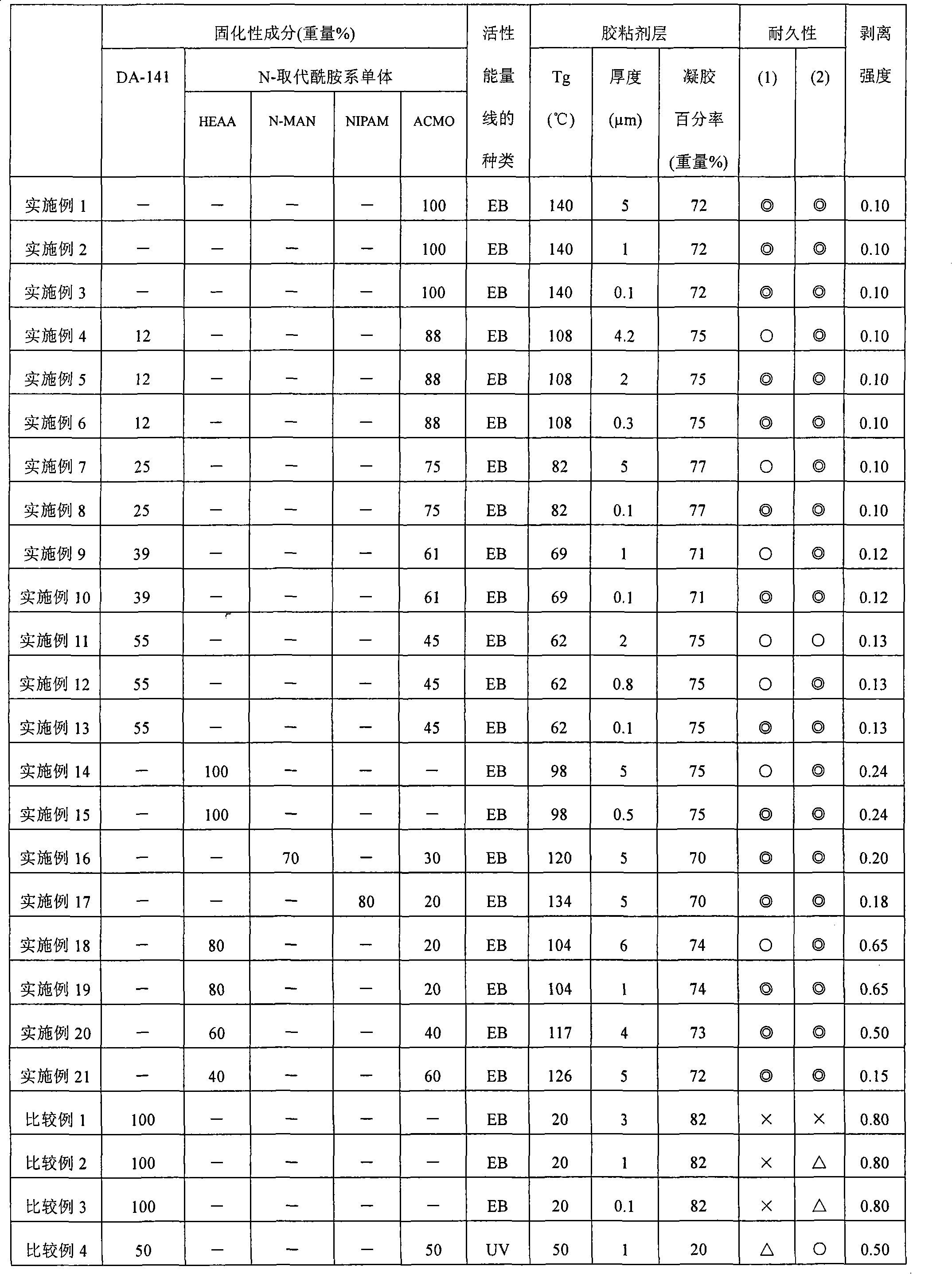

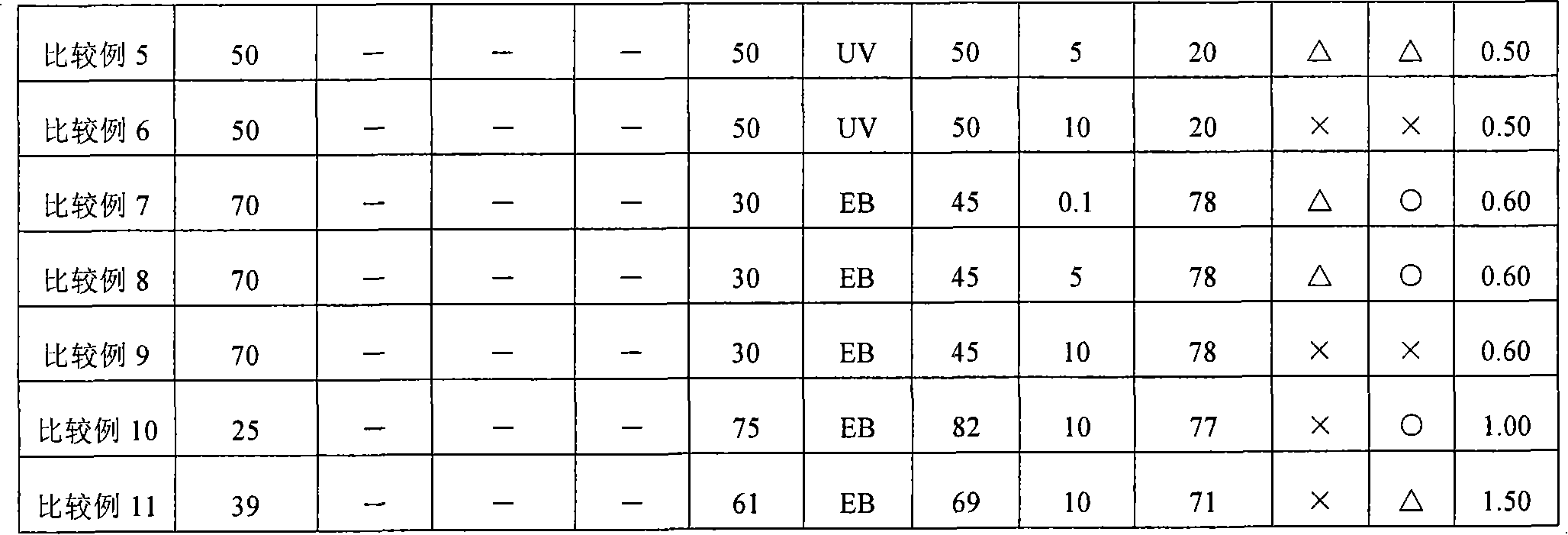

Embodiment 2~21、 comparative example 1~11

[0172] In Example 1, when the kind of curable component was used together, except having changed the ratio and the thickness of the adhesive layer as shown in Table 1, it carried out similarly to Example 1, and obtained the polarizing plate. In addition, in Comparative Examples 4-6, 3 weight part of polymerization initiators were added and used with respect to 100 weight part of curable components. In addition, the gravure roll changes into a mirror surface at 0.1μm, 0.3μm, and 0.5μm, #300 at 0.8μm and 1μm, #280 at 2μm, #250 at 3μm, and #250 at 4μm according to the thickness of the adhesive layer. and 4.2μm change to #220, change to #180 at 5μm and 6μm, change to #120 at 10μm. Table 1 shows the Tg and gel percentage of the adhesive layer of each example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com