Process for abstracting high-purity tanshinol form salvia

A high-purity technology of danshensu, which is applied in the field of herbal medicine, can solve the problems of increasing the chance and content of organic solvent residues, which is not conducive to industrialization, and high production costs, and achieves the effects of low cost, prevention of oxidative deterioration, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

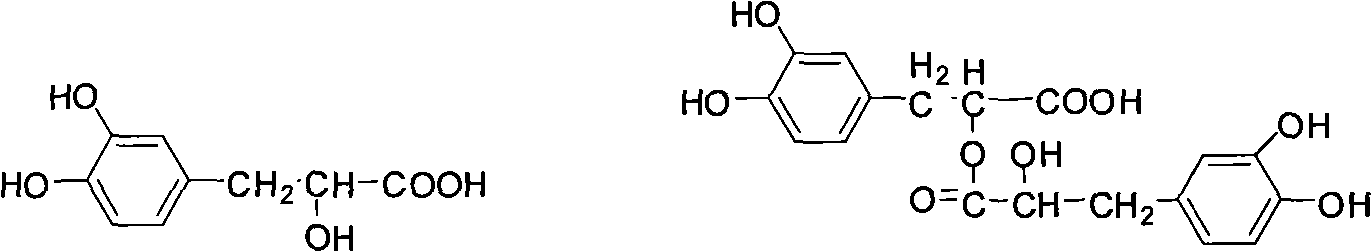

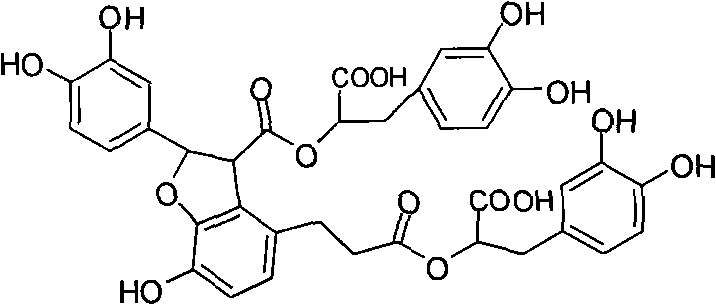

Method used

Image

Examples

Embodiment 1

[0028] Take 5 kg of Danshen slices, crush them, add 75 L of sodium hydroxide solution with a pH of 8, extract by hot dipping at 60°C for 3 times, each time for 0.5 h, and combine the extracts for 3 times. Adjust the pH to 1 with dilute hydrochloric acid, at this time a large amount of precipitate precipitated, which was removed by filtration. Concentrate the supernatant under reduced pressure at 60°C to 2000ml, add ethanol and stir thoroughly, and make the alcohol concentration reach 70%. After standing at room temperature for 24 hours, filter out the precipitate, and concentrate the filtrate under reduced pressure until it has no alcohol smell. The 5kg AB-8 macroporous resin column on the concentrated solution is first washed with 2 times the volume of water, and this part is impurity components, which is treated separately; then washed with 3 times the volume of water to collect this part. Concentrate the aqueous solution under reduced pressure at 60°C to about 500ml, add pH...

Embodiment 2

[0030] Take 10 kg of Danshen slices, crush them, add 120 L of potassium hydroxide solution with a pH of 10, heat-dip and extract twice at 80°C for 1 hour each time, and combine the two extracts. The pH was adjusted to 2 with acetic acid, at which point a large amount of precipitate precipitated, which was removed by filtration. The supernatant was concentrated under reduced pressure at 70°C to 3000ml, added ethanol and stirred thoroughly, and the alcohol concentration reached 85%. After standing at 4°C for 18 hours, the precipitate was filtered off, and the filtrate was concentrated under reduced pressure until it had no alcohol smell. The 10kg HP-20 macroporous resin column on the concentrated solution is first washed with 2 times the volume of water, and this part is impurity components, which is treated separately; then washed with 5 times the volume of water to collect this part. Concentrate the aqueous solution under reduced pressure at 70°C to about 500ml, add potassium ...

Embodiment 3

[0032]Take 2 kg of Danshen slices, crush them, add 20 L of ammonia solution with a pH of 9, heat soak and extract at 75°C for 3 times, each time for 1 hour, and combine the extracts for 3 times. Adjust the pH to 1.5 with dilute sulfuric acid, at this time a large amount of precipitate precipitated, which was removed by filtration. Concentrate the supernatant under reduced pressure at 65°C to 1000ml, add ethanol and stir thoroughly, and make the alcohol concentration reach 75%, let it stand at 4°C for 12 hours, filter out the precipitate, and concentrate the filtrate under reduced pressure until it has no alcohol smell. The 2kg D101 macroporous resin column on the concentrated solution is first washed with 3 times the volume of water, and this part is impurity components, which is treated separately; then washed with 4 times the volume of water to collect this part. Concentrate the aqueous solution under reduced pressure at 60°C to about 500ml, add ammonia solution of pH 9 to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com