Applications of montmorillonite for bacteriostasis and corrosion protection in paper making process

A paper-making process and montmorillonite technology, which is applied in the direction of adding paper and inorganic compounds, etc., can solve the problems of polluted water resources, insufficient dosage, and insufficient sterilization spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

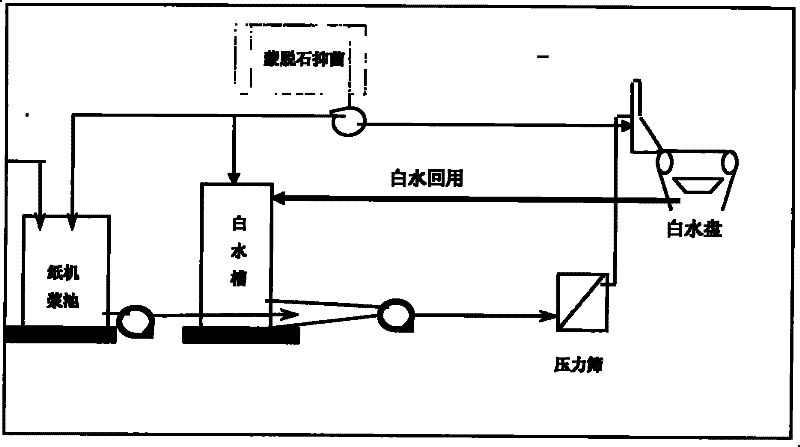

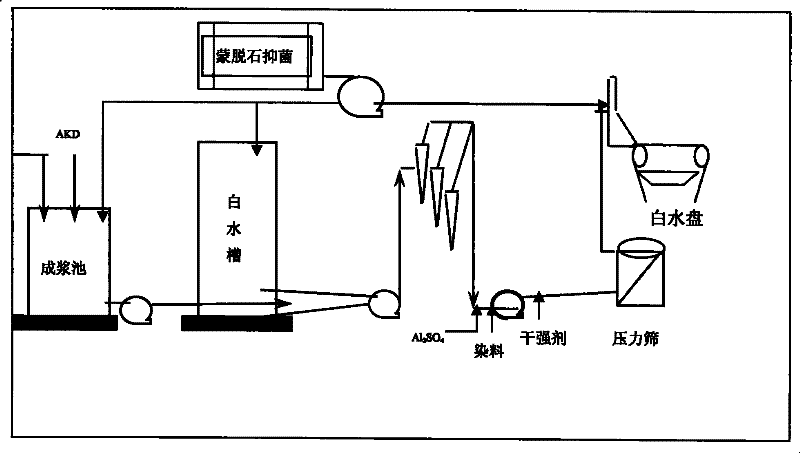

Image

Examples

Embodiment 1

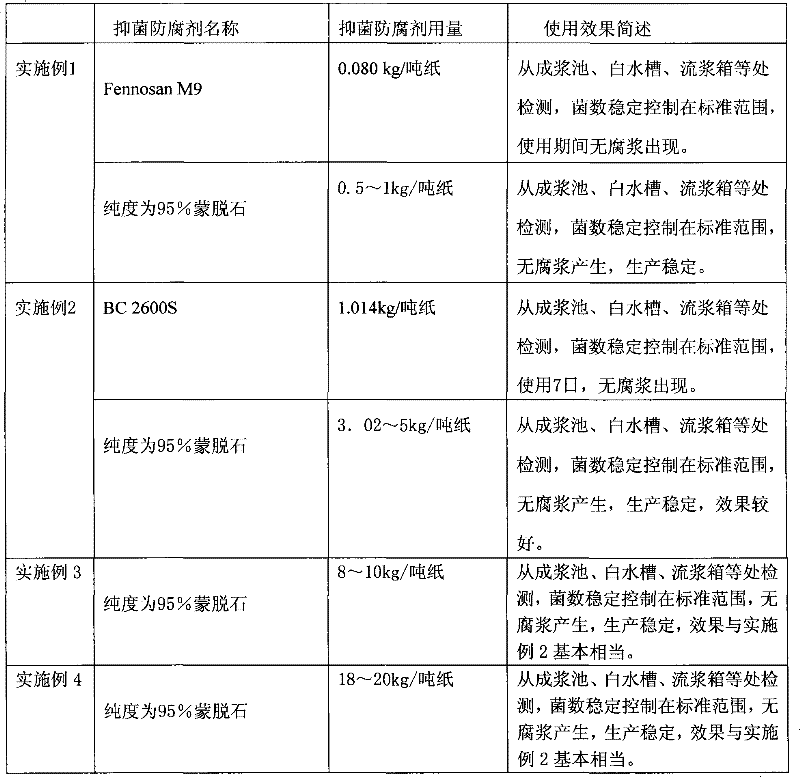

[0016] Embodiment 1: A certain paper company

[0017] Explanation: The company originally used Kemira Fennosan M9 antibacterial agent. During the test period, montmorillonite antibacterial preservative was added continuously at three points in the paper machine pulp tank, white water tank and headbox, at a rate of 0.5-1kg / Tons of paper, according to observation for a period of time, the antibacterial effect is obvious, and no sludge is produced.

Embodiment 2

[0018] Example 2 Another paper company

[0019] Explanation: The company originally used Kamaz BC 2600S antibacterial preservative, and after trialing 3.02-5kg / ton of montmorillonite antibacterial preservative, the production was normal and no pulp was produced.

[0020] In order to verify the effective amount of antibacterial use of montmorillonite in the papermaking process, the present invention has carried out the test of using more than 5 kilograms of montmorillonite for antibacterial per ton of paper, and now provides the following 2 examples of embodiments:

Embodiment 3

[0021] Embodiment 3: according to figure 1 In the adding method shown, 8 to 10 kg of montmorillonite are continuously added at three points in the pulp tank of the paper machine, the white water tank and the headbox. Continuous production for 7 days without slime.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com