Water-proofing material for adhesive joint between solid objects

A waterproof material and bonding technology, which is applied in the field of plastic-steel cement, can solve the problems of mildew, yellowing and breaking of the waterproof edge of glass glue, and achieve the effect of tough structural strength and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

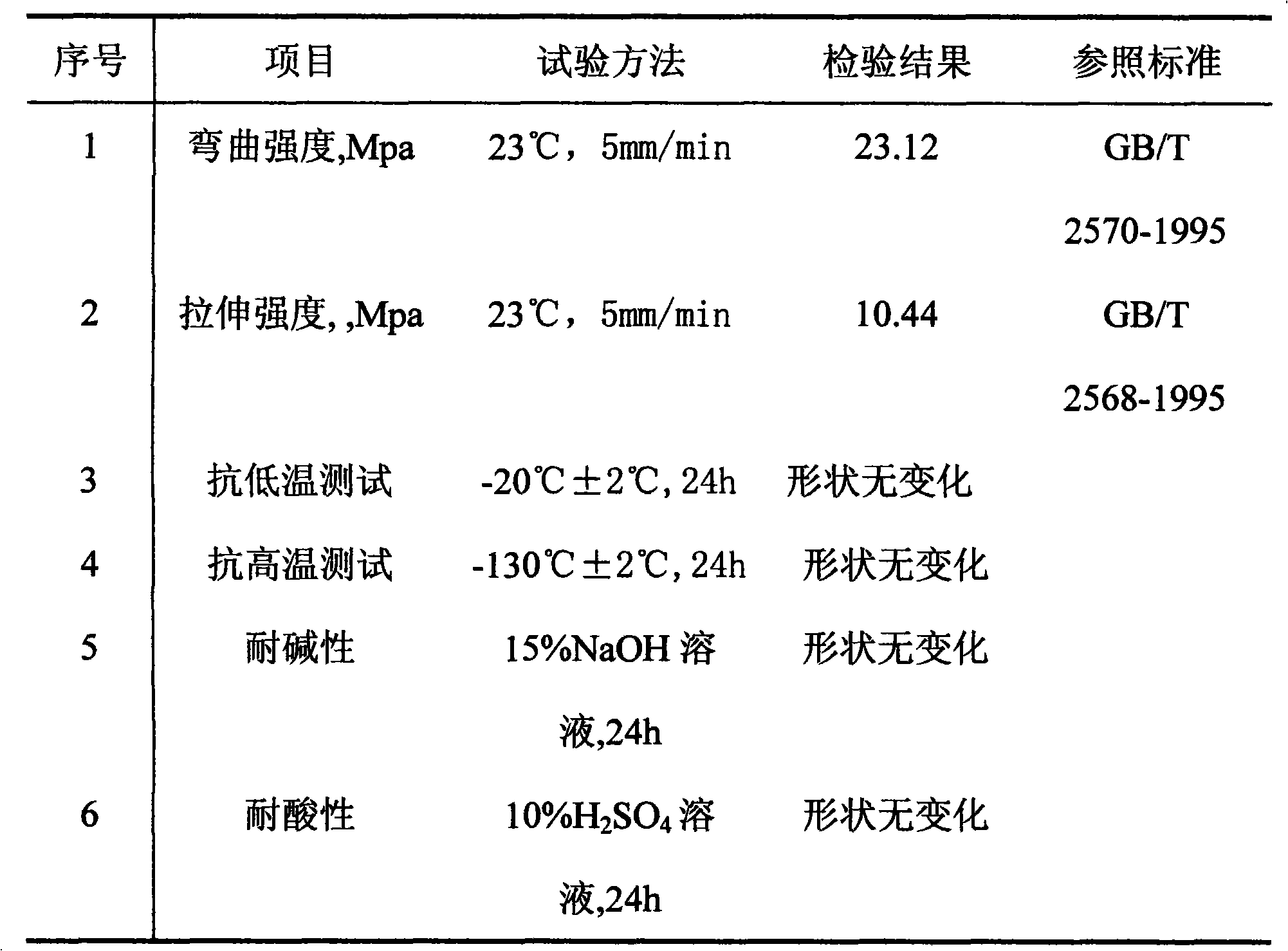

Image

Examples

Embodiment 1

[0024] The waterproof material used for solid bonding described in this embodiment - plastic cement, includes two components of A and B, wherein the ratio of mass content:

[0025] A component, epoxy resin: calcium carbonate: talc: phthalate = 4:5:1:1

[0026] Component B, polyamide curing agent: calcium sulfate: calcium carbonate: talcum powder = 3:3:1:3.

Embodiment 2

[0028] The waterproof material used for solid bonding described in this embodiment - plastic cement, includes two components of A and B, wherein the ratio of mass content:

[0029] A component, epoxy resin: talc powder: phthalate = 3:6:1

[0030] B component, polyamide curing agent: talcum powder: acetone thinner = 3:6:1

Embodiment 3

[0032] The waterproof material used for solid bonding described in this embodiment—plastic steel clay includes two components of A and B, wherein:

[0033] A component comprises the epoxy resin that mass content is 25%, the phthalate ester that mass content is 1%, the additive mass content ratio of remainder is calcium carbonate: CCR: talcum powder: magnesium strong powder=1:1 :1:1;

[0034] Component B includes a polyamide curing agent with a mass content of 20%, and the remaining additive is 80% talcum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com