Radix acanthopanacis senticosi tea and its preparation technique

A preparation process and technology for Acanthopanax senticosus tea, which is applied in the field of beverages made of natural plants and Chinese medicinal materials, can solve the problems of aggravated body bones, dark color of tea soup, and long frying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

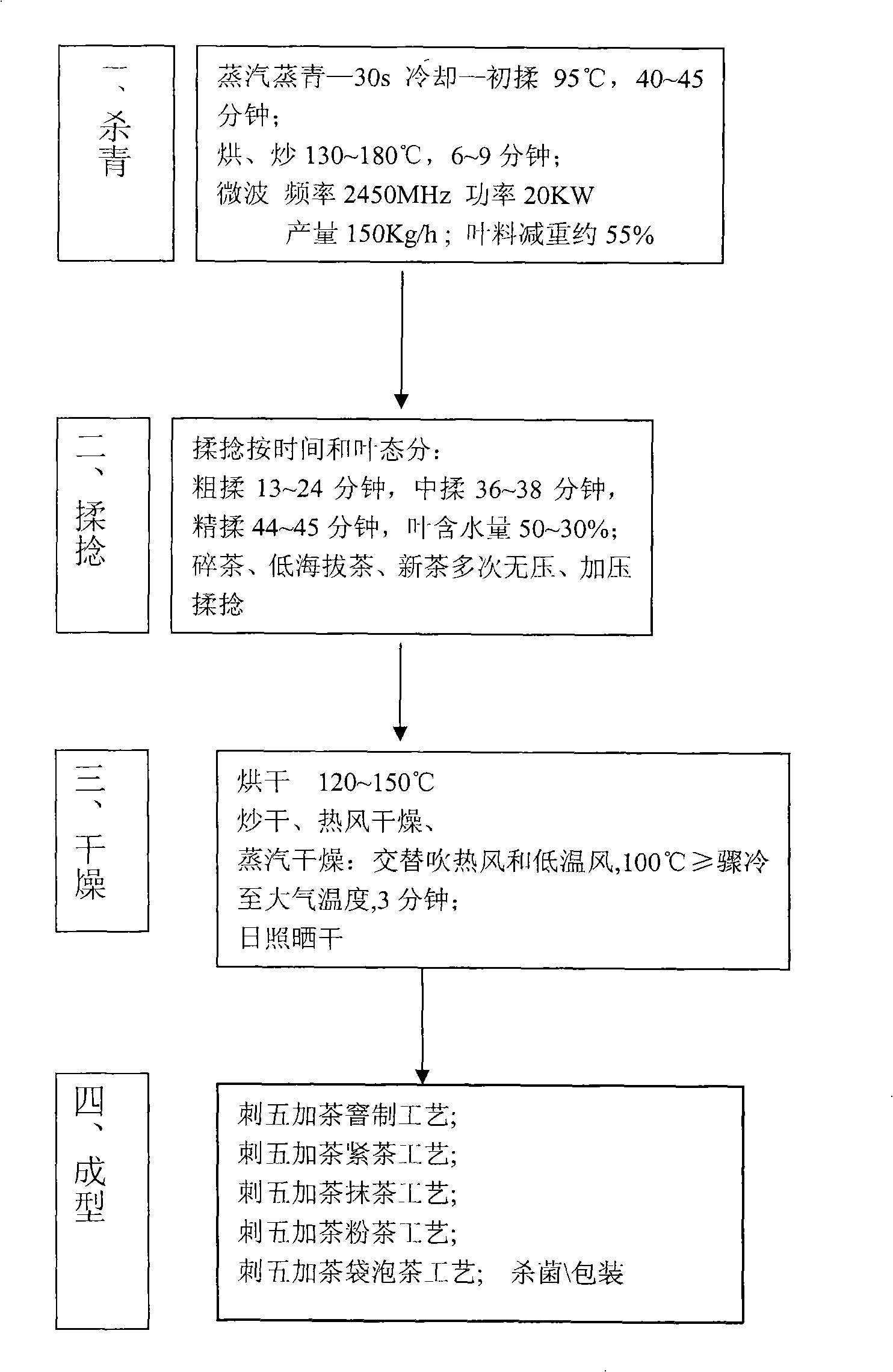

[0008] Preparation Technology of Acanthopanax Tea

[0009] The fresh leaves of Acanthopanax senticosus are picked at the best length: 3.5-7cm for large and medium leaves, and 2-3.5cm for small leaves. Picking must be fine and uniform in size, and rainwater leaves, diseased leaves, purple leaves, and dew leaves must not be picked, and must be dried. When picking, it is best to store them in bamboo baskets, and it is forbidden to use all kinds of used bags to prevent the fresh leaves from turning red and hot. After entering the factory, loosen and spread, the thickness does not exceed 10cm, and the spreading time is no less than 6-8 hours for single leaves, and no less than 5-6 hours for bud leaves. Fresh leaves can be fried after the green air is lost and the aroma is transparent. , the stall site must comply with organic food standards.

[0010] Before processing, it is necessary to understand the water content of fresh leaves, treat them differently, and process them in bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com