Method for non-contact dynamic detection of solid contour

A dynamic detection and non-contact technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unreliable measured values, distortion of the surface to be measured, and inability to obtain measured values, so as to reduce hardware expenditure, Effect of reduced hardware outlay, reduced time to set up and calibrate measurement equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

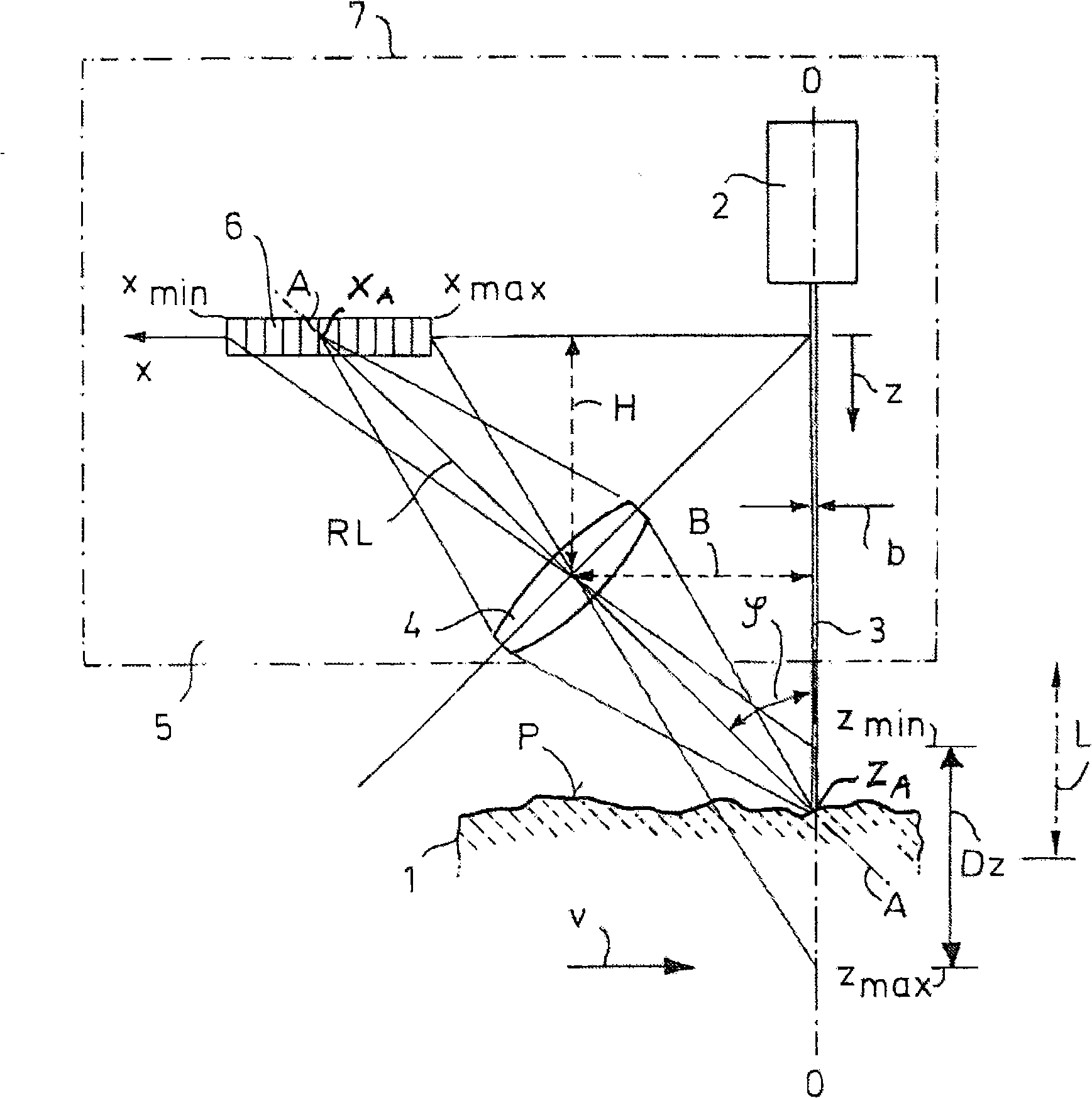

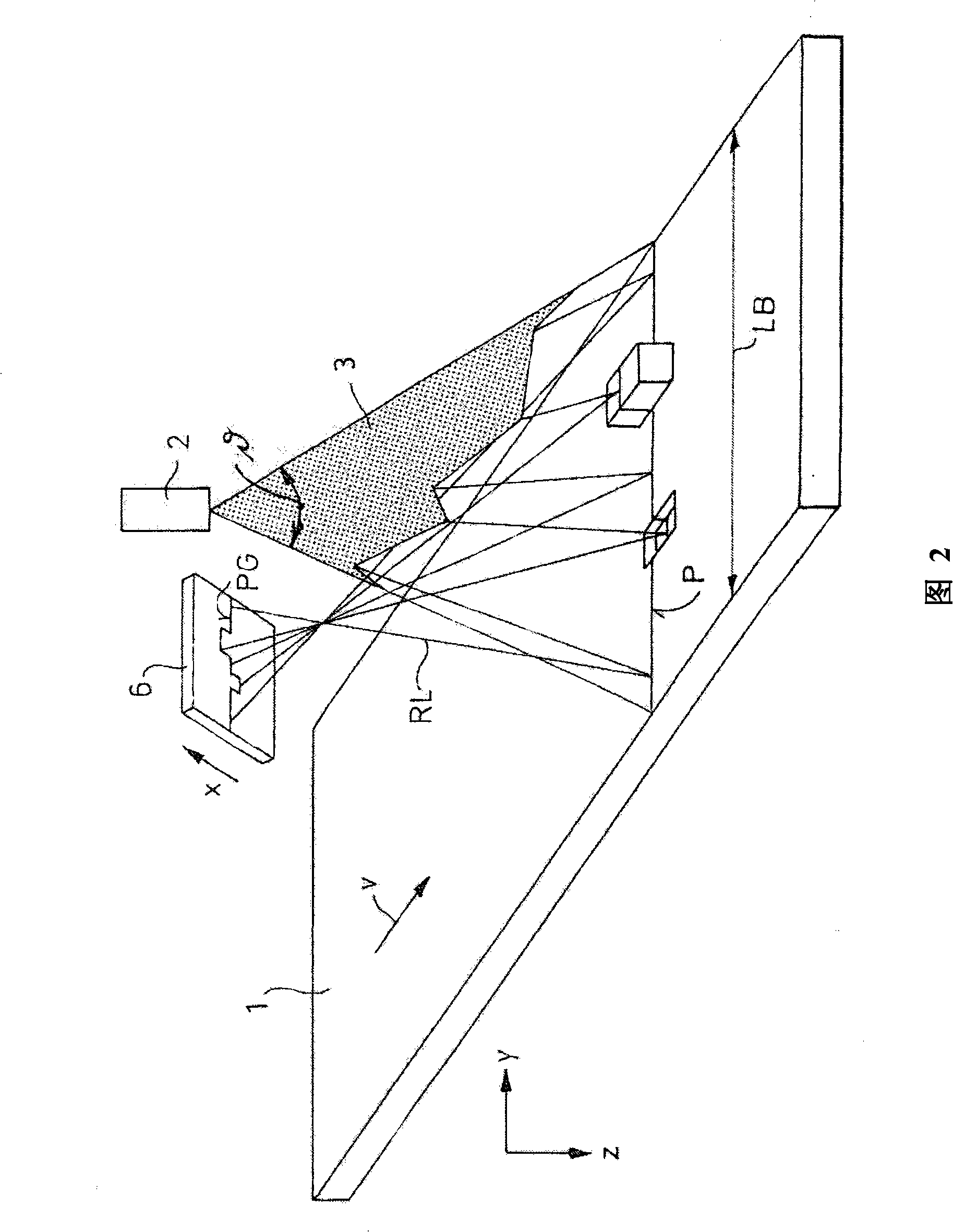

[0072] first as figure 1 As shown in the two-dimensional schematic diagram of the object to be measured, a solid 1 is moving at a velocity v. According to the principle on which the method of the present invention is based, a beam of light emitted from a laser 2 is focused by an optical element (not shown) so that the The width b of the beam falls within a specified range in the measuring range Dz consisting of a maximum measurable value z of the depth or profile height z max with a minimum z min resulting from the difference between. In this case, the light beam is spread out to form a light strip 3 as shown in the three-dimensional representation in FIG. 2 .

[0073] The incident position z of the light band on the surface of solid 1 A The diffuse light scattered there (reflected light RL) forms a measurement spot which is also perceivable in directions deviating from the direction of incidence determined by the optical axis 0-O of the laser 2 .

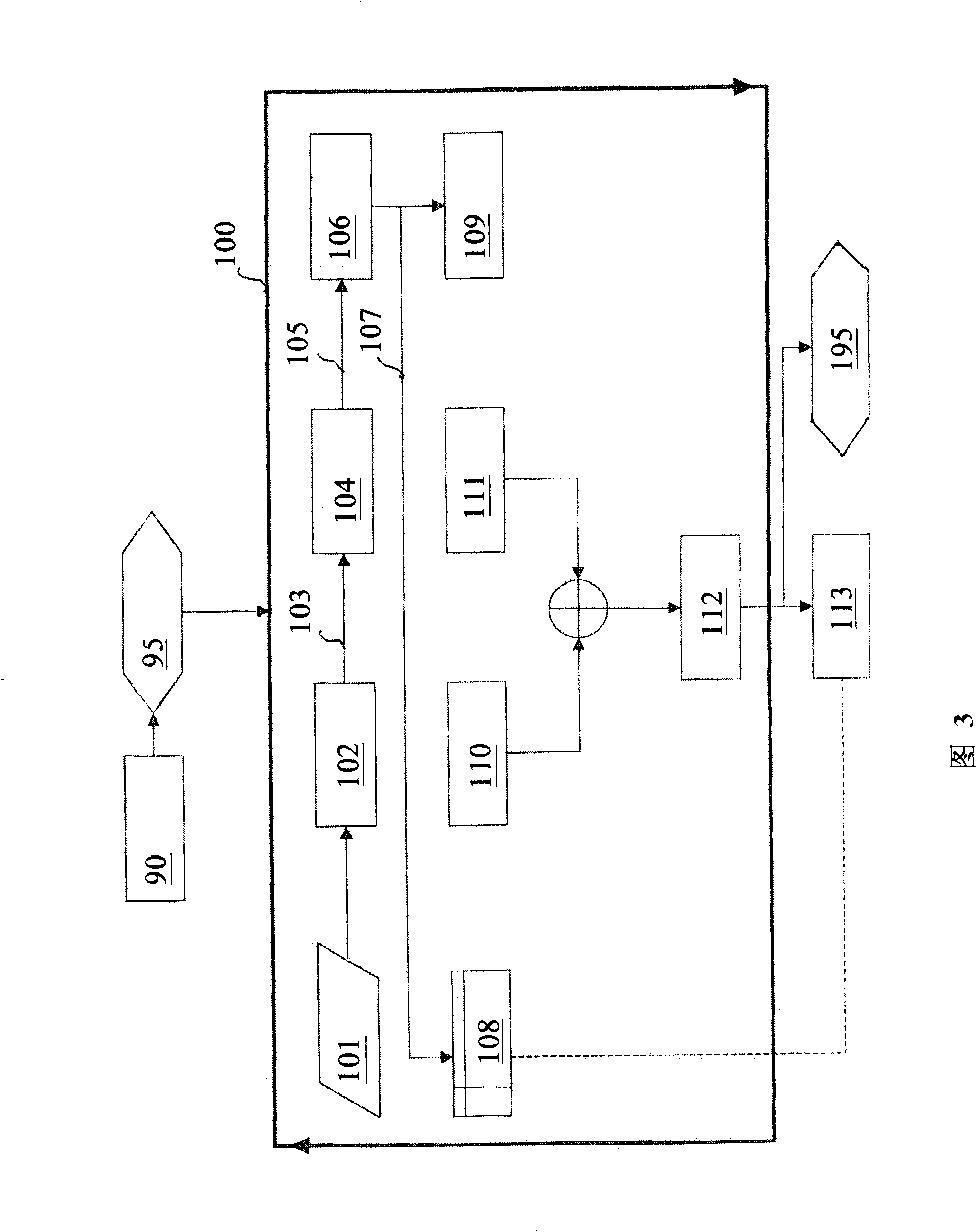

[0074] If the measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com