Method for changing energize mode to realize different mode electromagnetic detection

A technology of electromagnetic detection and excitation mode, applied in the direction of material magnetic variables, etc., can solve the problems of inconvenience, high cost of instrument production, unsuitable detection of deep layers of metal materials, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

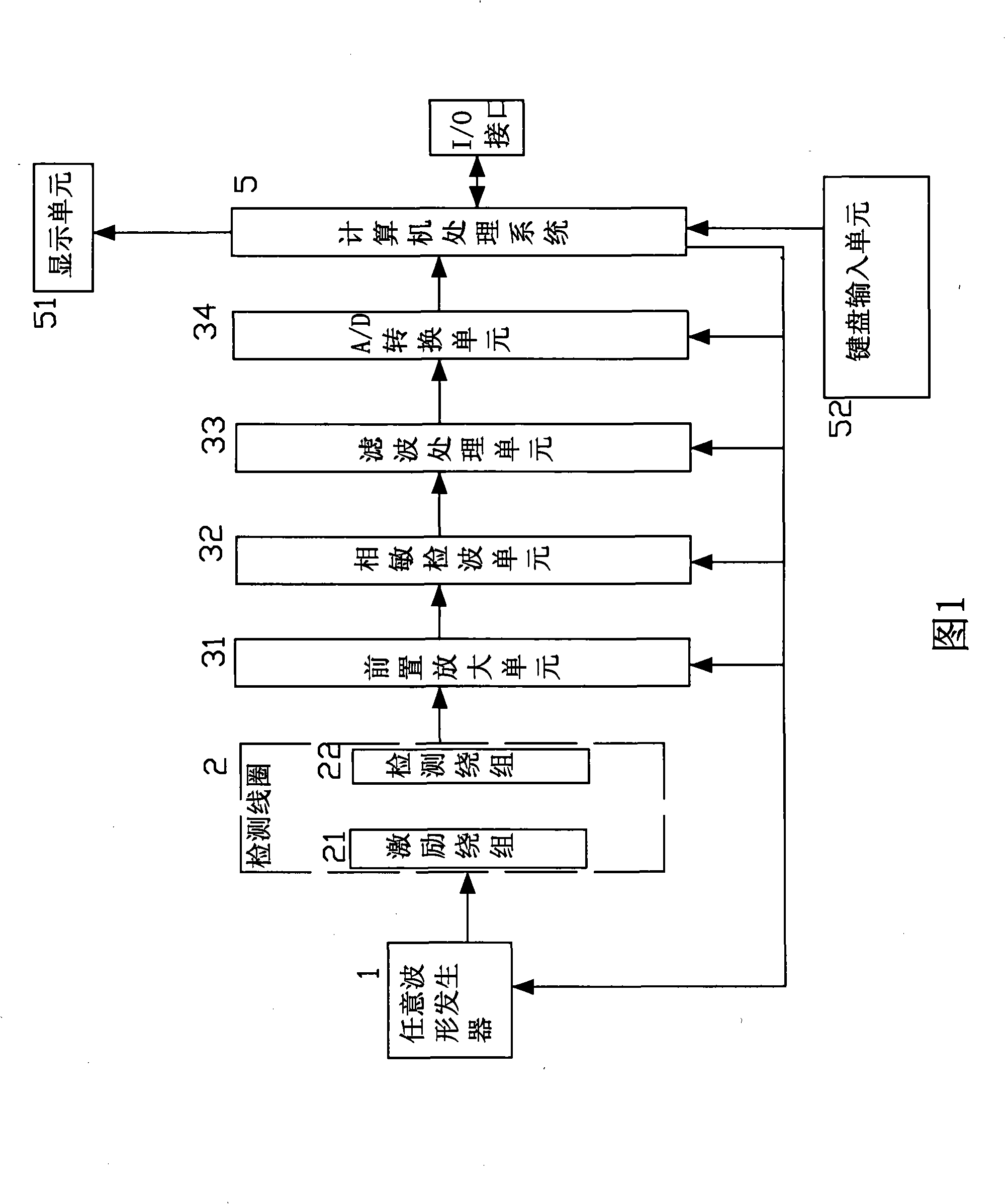

[0036] Referring to the accompanying drawings, a method for realizing electromagnetic detection in different ways by changing the excitation mode of the present invention can be realized by the following devices, such as an arbitrary waveform generator 1, a detection coil 2, and a preamplifier unit 31 , phase-sensitive wave detection unit 32, filter processing unit 33, A / D conversion unit 34, computer processing system 5, display unit 51, keyboard input unit 52, arbitrary waveform generator 1 is controlled by computer processing system 5, the detection coil 2 The excitation winding 21 is connected to the output of the arbitrary waveform generator 1, the output of the detection winding 22 of the detection coil 2 is connected to the input of the preamplifier unit 31, and the output of the preamplifier unit 31 is connected to the input of the phase sensitive detection unit 32, and the phase The output of the sensitivity detection unit 32 is connected to the input of the filter pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com