Dynamic detecting process of well control product and well head apparatus under high and low temperature state

A wellhead device and dynamic detection technology, which is applied in the direction of measuring device, machine/structural component test, and by measuring the increase and decrease rate of fluid, can solve the problems of increasing the incidence of safety accidents, low reliability, and inability to continue to use , to achieve the effect of reducing the incidence of safety accidents, improving safety and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

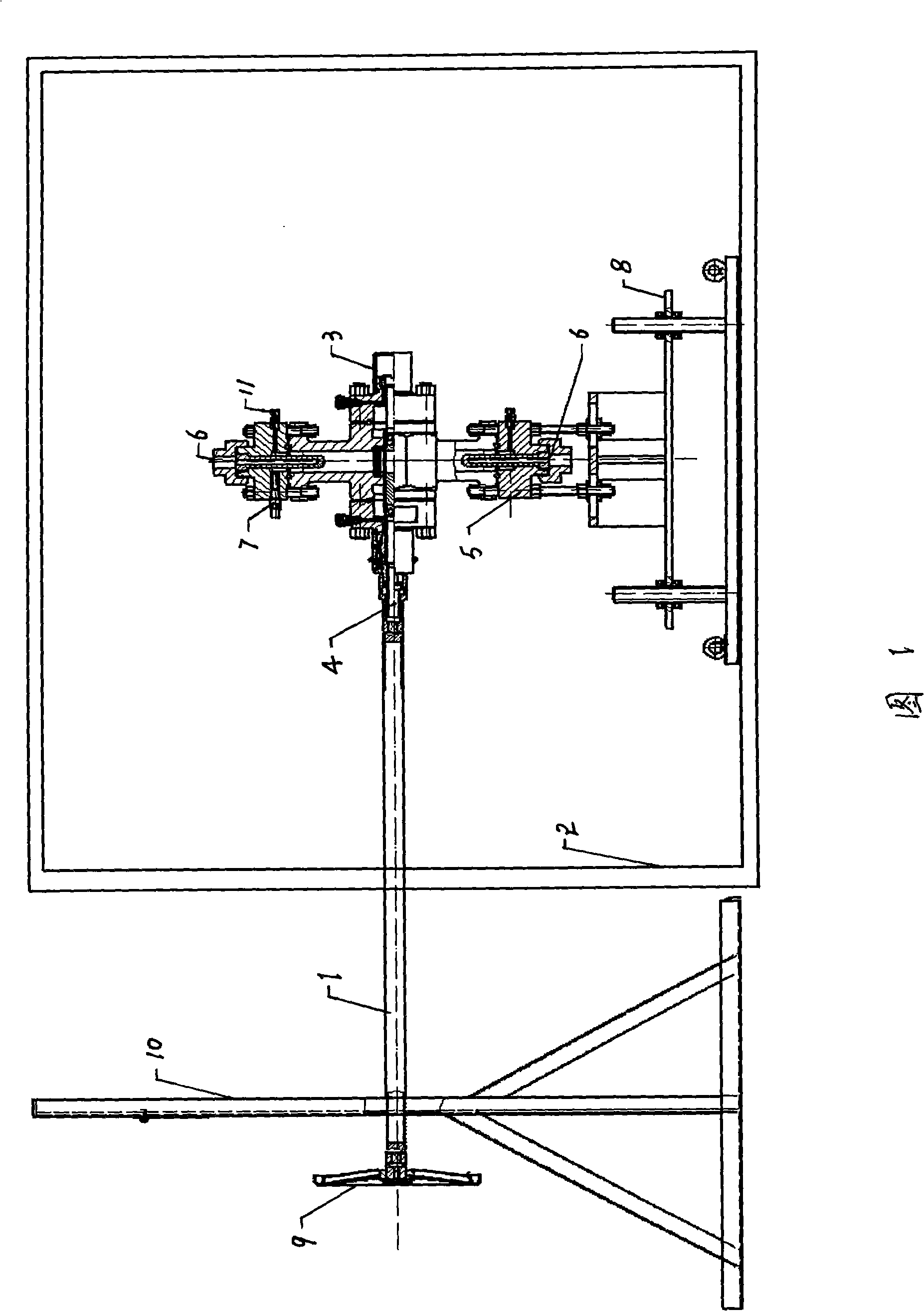

[0022] A dynamic detection process for well control products and wellhead devices under high and low temperature conditions, including a. installing the detected part 3 on the detection device, and then connecting the detected part 3 with a pressurizing device; b. opening the detection device Heater 6, to heat the air temperature in the chamber of the tested part 3 to a rated high temperature of 60°C or use the ambient low temperature box 2 to reduce the temperature to a rated low temperature of -18°C, and use the computer control system to maintain the temperature at the rated temperature value; c , Turn on the pressurization device, pressurize the tested part 3 to the rated pressure of 1MPa; d, through the valve stem 4 connected to the tested part 3, open it repeatedly 20 times under the rated working pressure; e, stabilize the pressure for 0.5 hours, Collect the temperature and pressure values of the tested part 3, and compare the collected temperature and pressure values ...

Embodiment 2

[0025] A dynamic detection process for well control products and wellhead devices under high and low temperature conditions, including a. installing the detected part on the detection device, and then connecting the detected part with the air compressor unit; b. turning on the heater of the detection device , heat the air temperature of the inner chamber of the tested part to the rated high temperature of 121°C or use the ambient low temperature box to reduce the temperature to the rated low temperature of -60°C, and use the computer control system to keep the temperature at the rated temperature value; c. Turn on the air compressor unit , Pressurize the tested part to the rated pressure of 140MPa; d. Repeatedly open 30 times under the rated working pressure through the valve stem connected to the tested part; e. Stabilize the pressure for 2 hours, collect the temperature and pressure of the tested part Compare the collected temperature and pressure values with the rated temp...

Embodiment 3

[0027]A dynamic detection process for well control products and wellhead devices under high and low temperature conditions, including a. installing the detected part on the detection device, and then connecting the detected part with the air compressor unit; b. turning on the heater of the detection device , heat the air temperature of the inner chamber of the tested part to the rated high temperature of 80°C or use the ambient low temperature box to reduce the temperature to the rated low temperature of -30°C, and use the computer control system to keep the temperature at the rated temperature value; c. Turn on the air compressor unit , Pressurize the tested part to the rated pressure of 50MPa; d. Repeatedly open 40 times under the rated working pressure through the valve stem connected to the tested part; e. Stabilize the pressure for 1 hour, collect the temperature and pressure of the tested part Compare the collected temperature and pressure values with the rated temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com