Disc spring type axial vibration acceleration tool

A technology of axial vibration and disc spring, which is applied in the field of disc spring type axial vibration speed-up tools, can solve the problems of inconspicuous damping effect and unstable drilling of drill bits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

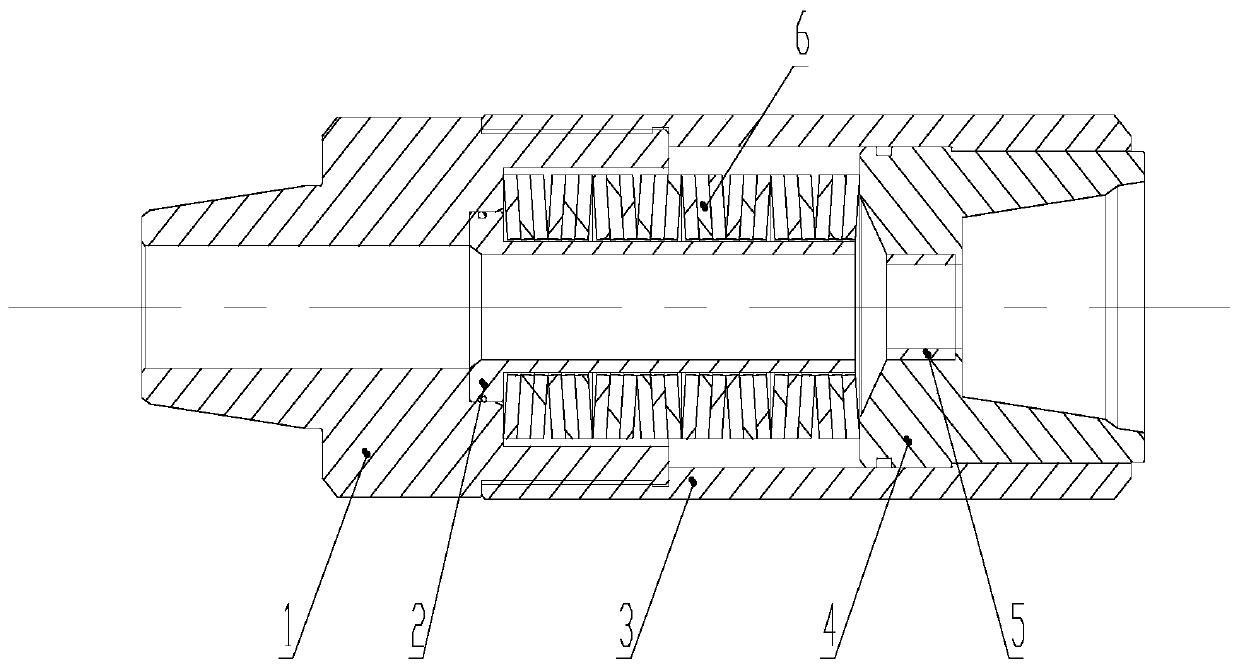

[0011] as attached figure 1 As shown, the disc spring type axial vibration speed-up tool includes an upper joint 1 and a lower joint 4, the lower end of the upper joint 1 is threadedly connected to the shell 3, and the lower end of the upper joint 1 is located at the upper boss of the inner cavity of the shell 3; The lower joint 4 is installed on the lower boss inside; the liner 2 is installed in the concave platform at the top of the inner cavity of the upper joint 1, the disc spring 6 is set on the liner 2, and the nozzle is installed in the concave platform at the upper end of the lower joint 4 5. The upper and lower ends of the disc spring 6 are respectively against the upper end surface of the inner cavity of the upper joint 1 and the upper end surface of the lower joint 4; sealing rings are installed between the upper joint 1, the liner 2, the shell 3 and the lower jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com