Novel direct-connected single-stage pump

A single-stage pump, direct-connection technology, applied in non-variable-capacity pumps, pumps, pump devices, etc., can solve the problems of high production cost, unsightly, difficult disassembly and movement, etc., to meet the requirements of use, easy to implement and use. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

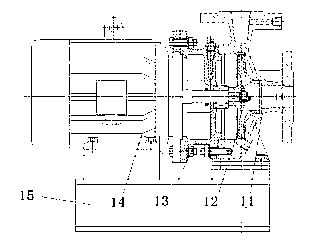

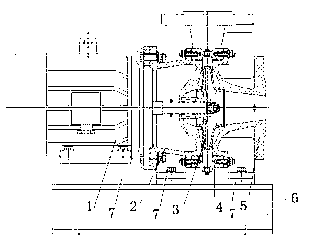

[0008] The figure includes a pump body, an impeller, a pump cover, a water inlet section, an extended shaft motor, and a base. The pump cover and the water inlet section are connected by studs, and the extended shaft motor is installed on one side of the pump cover. It is characterized in that: the pump cover, the water inlet section, and the feet under the extended shaft motor are all installed on a base.

[0009] The present invention is made up of pump body, impeller, pump cover, water inlet section, extended shaft motor, base, six parts. Casting feet are added to the water inlet section of the pump cover, and casting feet are removed from the pump body. The pump set is jointly supported by the motor feet, pump cover feet, and water inlet section feet. The pump body is connected by studs between the pump cover and the water inlet section, and the pump body can be rotated at any angle for assembly.

[0010] Moreover, the present invention is a front and rear door-opening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com