Platform capable of accurately detecting position and using method thereof

An accurate and platform-based technology, applied in the field of industrial automatic inspection, achieves the effects of simple programming, low price, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

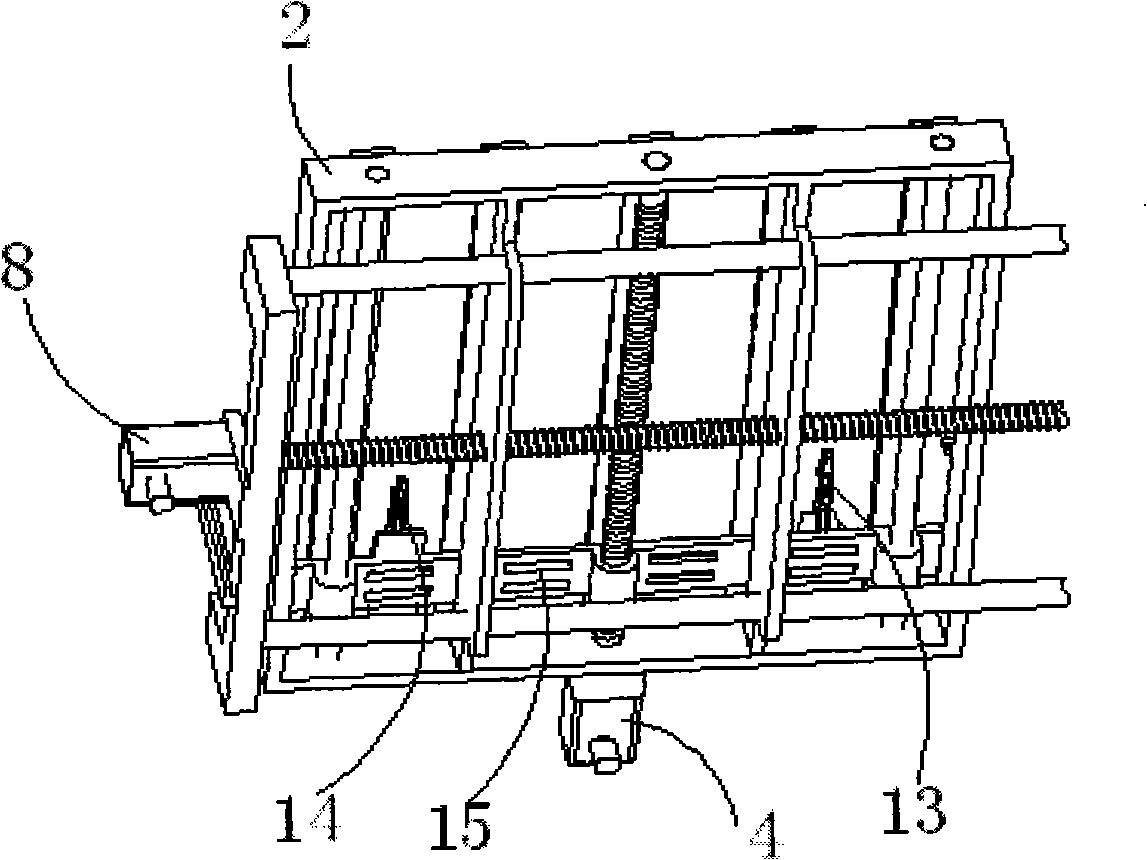

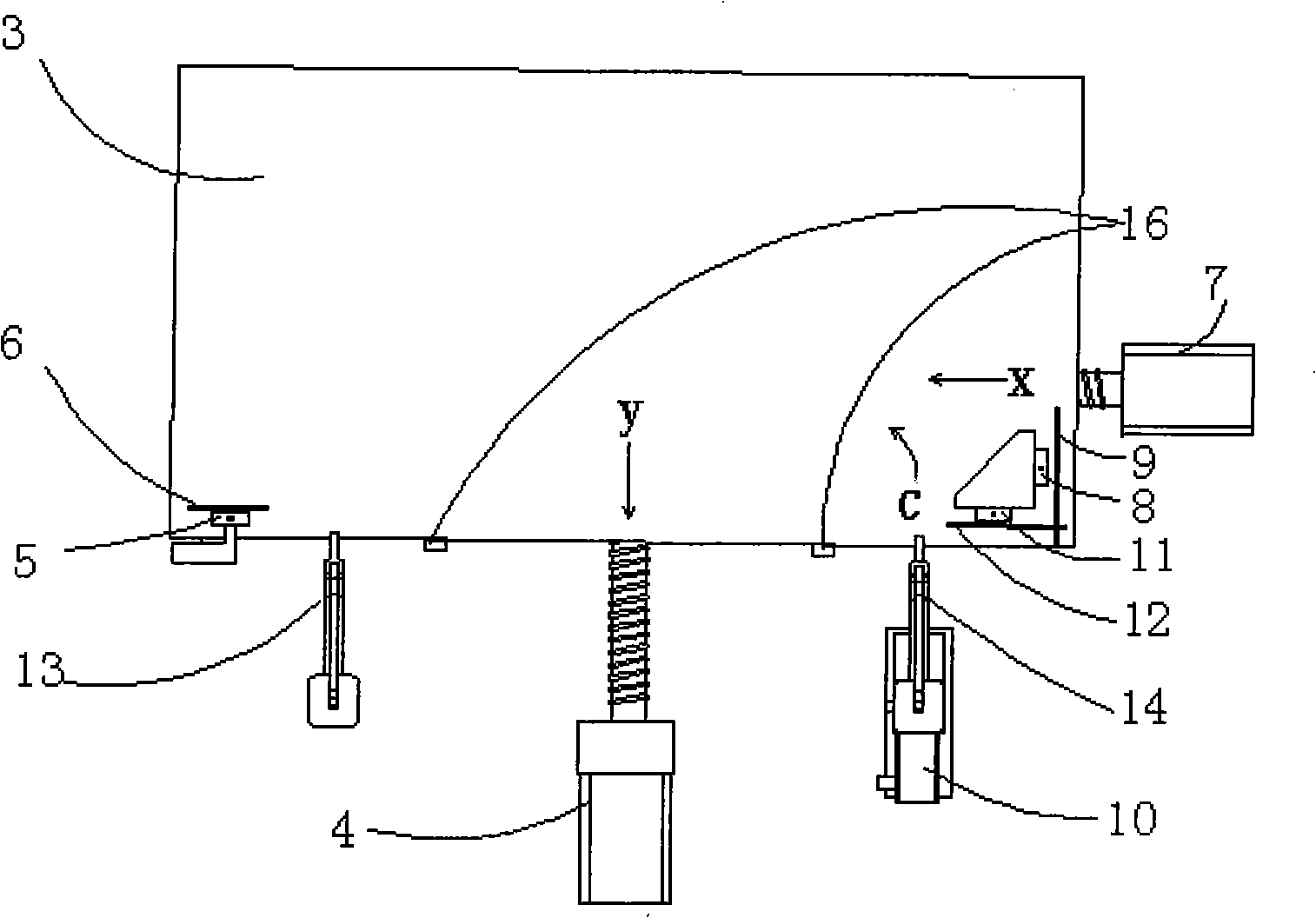

[0034] Embodiment 1: as figure 1 , 2 , 3, and 4, the present invention can accurately detect and locate plane lines. It includes a base 1 on which a mobile platform 2 that can move forward, backward, left, and right, carrying the workpiece 3 to be detected, is installed on the base 1. The workbench 2 includes a square frame, on which five strip-shaped plates form a table top, and the workbench 2 is installed on the base 1 through two sliding shafts so that it can move left and right, and the horizontal servo motor 7 drives the workbench 2 to move left and right through a screw; A workpiece clamping mechanism that is driven by a longitudinal servo motor 4 and can move back and forth is installed on the table 2. The fixed frame 15 of the workpiece clamping mechanism is installed in the square frame of the workbench 2 through two sliding shafts to move back and forth. The longitudinal servo motor 4 Drive the workpiece clamping mechanism to move back and forth through the lead sc...

Embodiment 2

[0035] Embodiment 2: The method of using a platform that can accurately detect and locate plane-like lines, such as image 3 Figure 4 shown, including the following steps:

[0036] (1) Start the equipment to power on the platform that can accurately detect and locate the plane lines so that each servo motor 4, 10, 7 is in the initial position;

[0037] (2) Place the workpiece 3 to be detected on the workbench, and close to the preliminary positioning baffle plate 16 of the workpiece. The offset direction and angle of the workpiece 3 are as follows: image 3 As shown, then start the cylinder clamps 13, 14 to clamp the workpiece 3 to realize the preliminary positioning of the workpiece;

[0038] (3) Start the detection and positioning scanning program, first start the longitudinal servo motor 4 to drive the workpiece clamping mechanism to move along the direction of the Y arrow, when the longitudinal color mark sensor 5 detects the longitudinal line mark 6, the longitudinal ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com