Main bearing multi-layer sealing structure of complete section tunnel boring machine

A technology of tunnel boring machine and main bearing, which is applied in the direction of engine seal, tunnel, mechanical equipment, etc., can solve the problems of main bearing lubricating oil leakage, shield construction loss, mud water and slag entering, etc., to ensure safe service life , safe and reliable sealing protection, innovative and scientific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

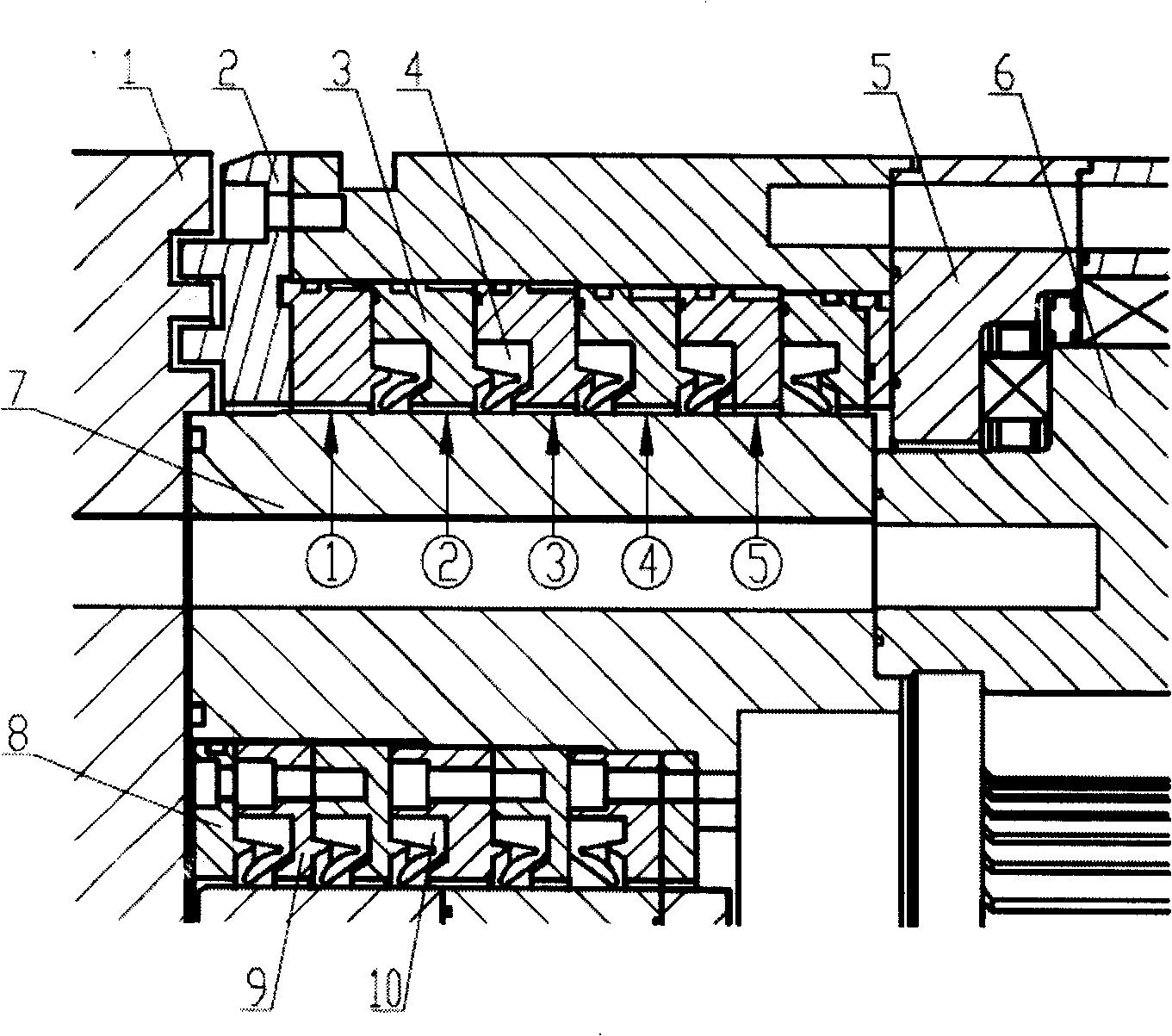

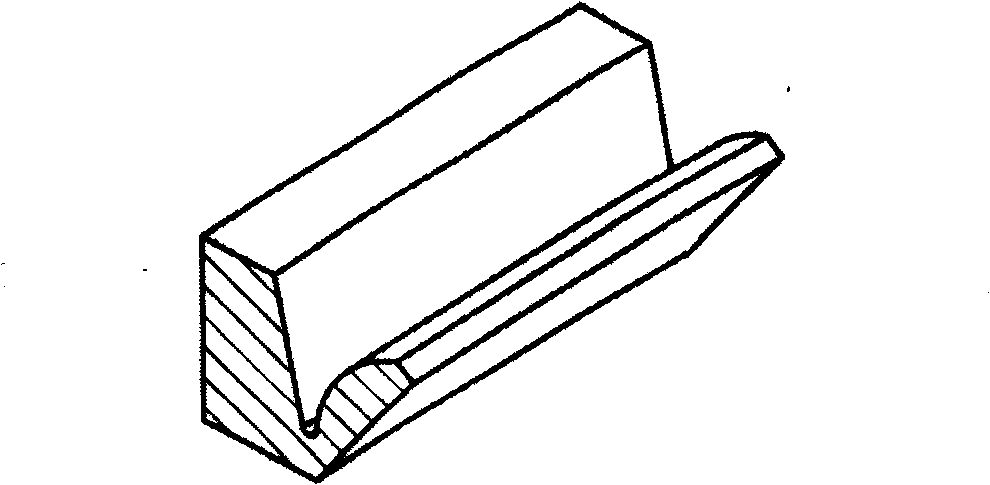

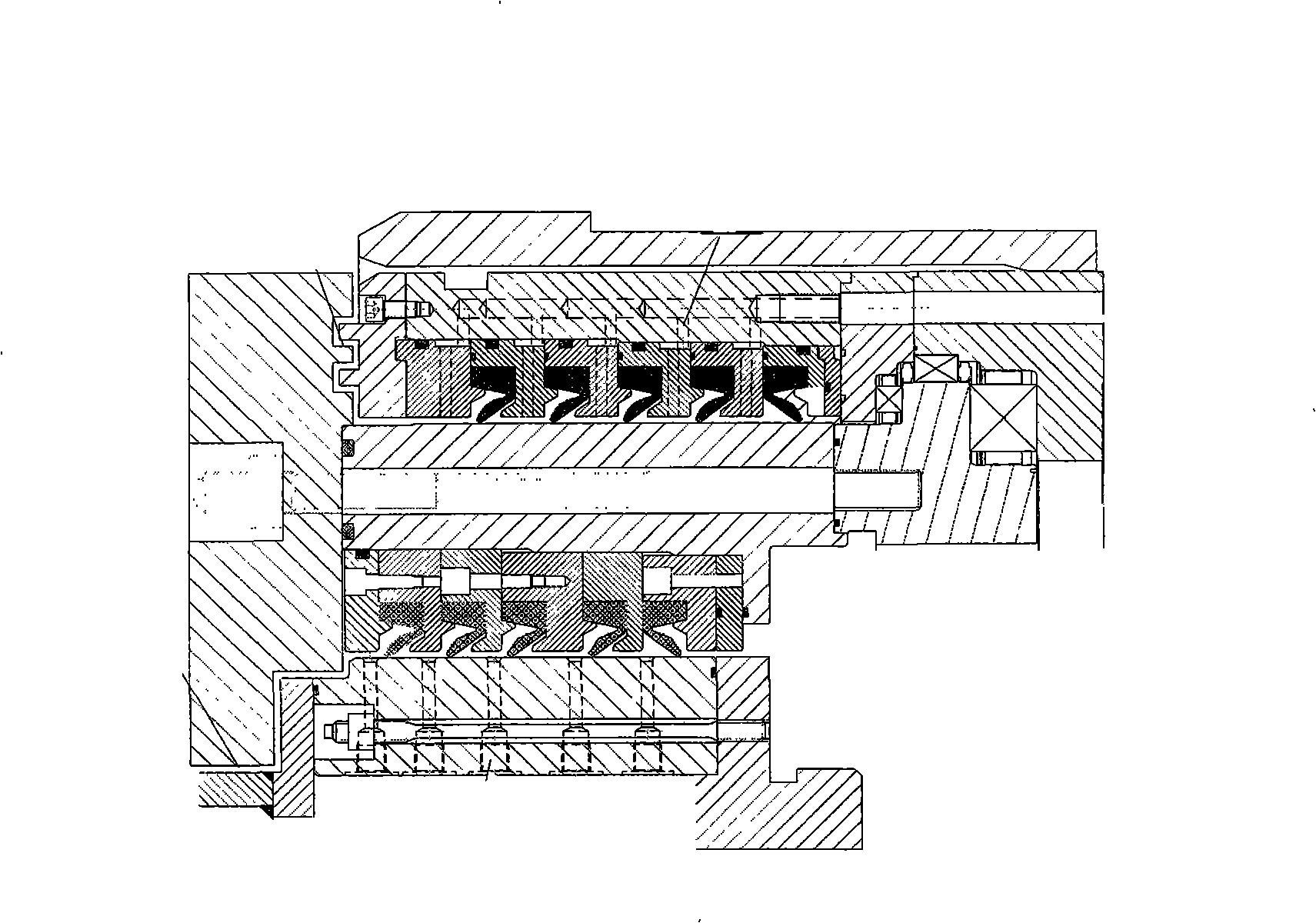

[0011] Referring to the accompanying drawings, the main bearing of the full-section tunnel boring machine has a multi-layer sealing structure. The whole device consists of a cutterhead support ring 1, an outer sealing ring pressure ring 2, an outer sealing ring spacer 3, a lip-shaped outer sealing ring 4, and an outer ring of the main bearing. 5. Main bearing inner gear ring 6, drum 7, inner sealing ring pressure ring 8, inner sealing ring spacer 9, lip-shaped inner sealing ring 10, the main bearing is divided into main bearing outer ring 5, main bearing The inner ring gear 6 is a drum 7 between the inner ring gear 6 of the main bearing and the supporting ring 1 of the cutter head, and there are three rows of cylindrical rollers between the inner and outer rings. The cutter head passes through the drum 7 and the inner ring gear 6 of the main bearing. The bolts are fastened and connected. When the pinion in the main drive drives the inner ring gear 6 of the main bearing to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com