Large-sized synthetic assembled structure apron plate

An enclosure and assembly technology, applied to building components, building structures, walls, etc., can solve problems such as insufficient strength, melting, and single function, and achieve good sound absorption and sound insulation effects, high strength, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

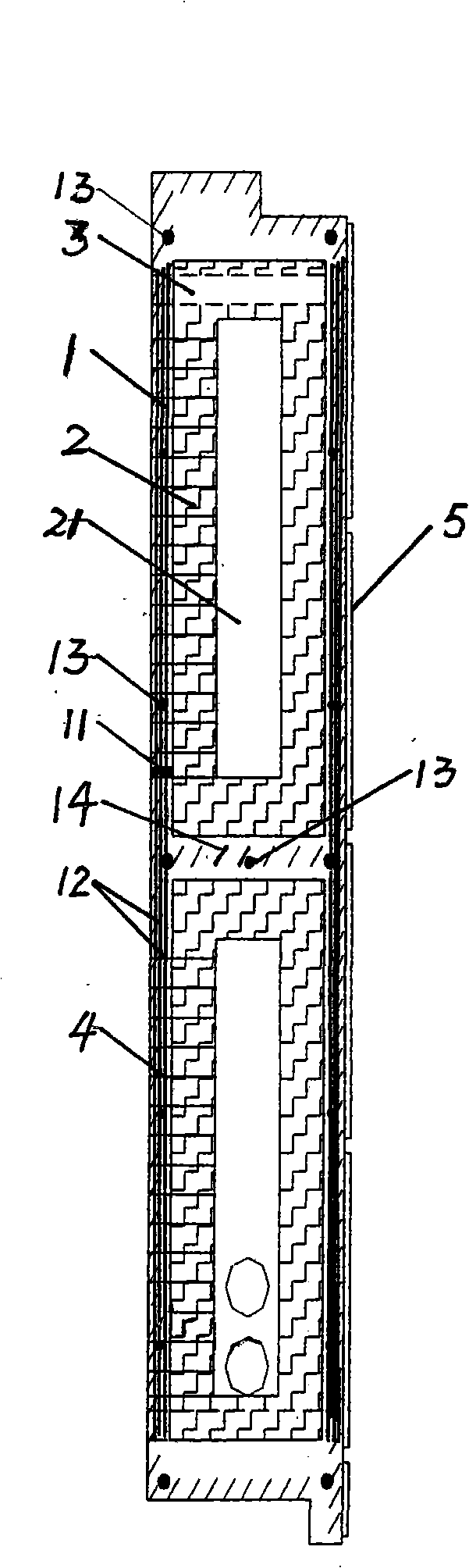

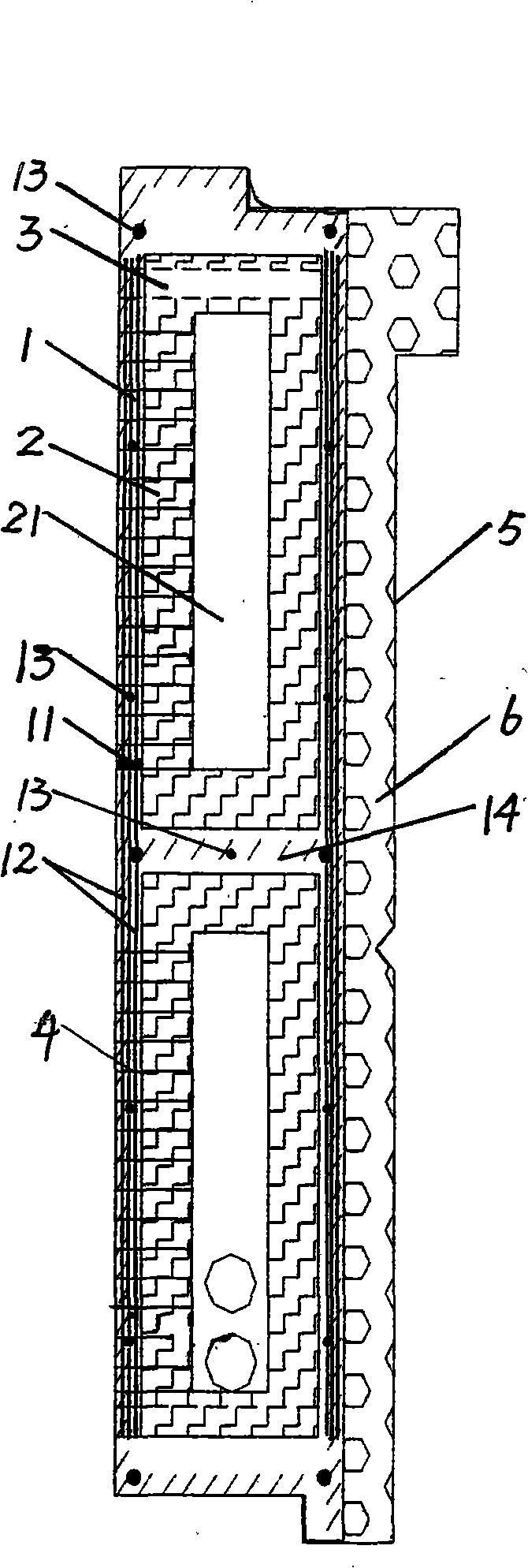

[0013] Embodiment 1, a large-scale composite assembled structure enclosure, including an outer protective casting layer 1 and a middle lightweight heat insulation filling layer 2, one outer side of the outer protective casting layer 1 is directly covered with a decorative layer 5, and the outer protective casting layer 1 is a pouring body of magnesium oxide, high-purity magnesium, ceramsite and water. The middle part of the pouring layer 1 is designed with a reinforced connecting frame 14, and a steel wire mesh 11 is laid in the pouring body. Both sides of the steel mesh 11 are covered with glass fiber cloth 12. Layer 1 and its reinforced connecting frame 14 are further provided with reinforced steel bars 13 at intervals.

[0014] The upper and lower end faces of the enclosure plate are L-shaped concave-convex openings, and reinforcement bars 13 are also placed in the L-shaped concave-convex openings, and connector bolts 3 are designed in the enclosure panels inside the L-shape...

Embodiment 2

[0016] Example 2, with reference to Example 1, the middle lightweight heat insulation filling layer 2 is a polystyrene foam filling layer, and one outer side of the outer protection casting layer 1 is covered with a metal decorative panel 5, and the outer protection casting layer 1 and the metal decoration The panels 5 are filled with polyurethane foam bonding insulation layer 6,

[0017] Explanation: In Example 1 and Example 2, the weight ratio of each component of the outer protective casting layer is 80-100 parts of magnesium oxide, 35-45 parts of high-purity magnesium, and 20-50 parts of ceramsite in 100 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com