Integrated gasification combined cycle thermoelectric oil gas multi-production process for efficient clean region

A technology of integrated coal gasification and combined cycle, which is applied in the petroleum industry, combined combustion mitigation, and combustible gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

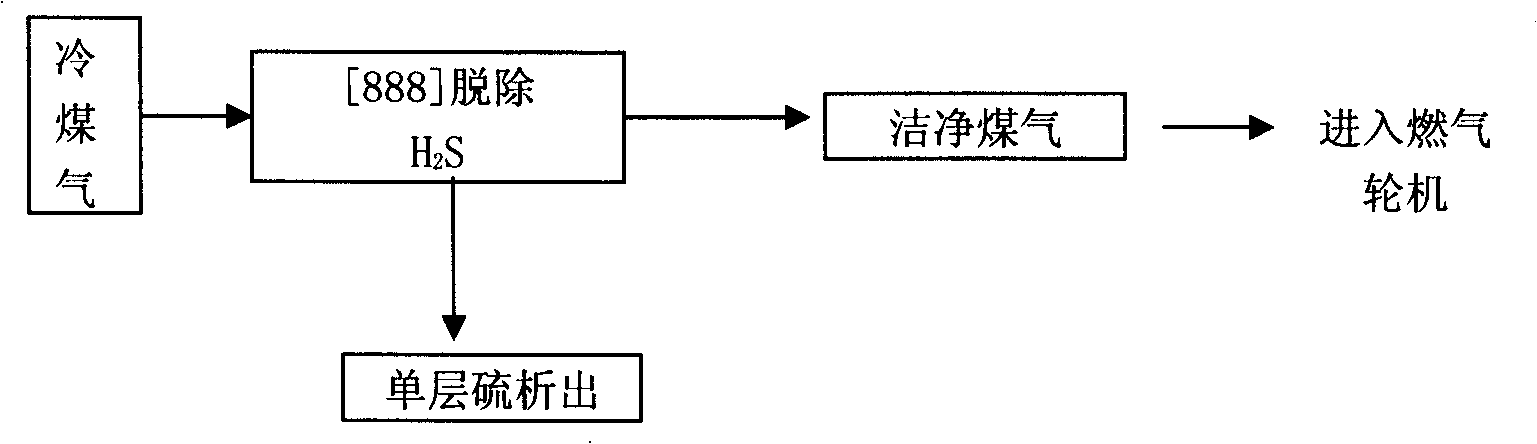

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0019] Project introduction: This invention combines some advantages of existing technologies at home and abroad in various parts, and the contributions of its team partners, aiming to form an efficient and clean area suitable for northern China as soon as possible Technology, in response to the calls of governments at all levels, improve the application of energy-saving technologies, make full use of limited coal resources, and completely change the current situation of high pollution and high emissions caused by direct coal-fired boilers. Complete the energy conservation and emission reduction tasks proposed by the State Council and governments at all levels as soon as possible.

[0020] The present invention is mainly developed by Shandong United Energy Technology Co., Ltd., and its joint research institutions are Jinan Design and Resea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com