Method for cooperative reclaiming flyash and sludge in refuse incineration

A waste incineration fly ash and recycling technology, applied in the field of environmental engineering, can solve problems such as restrictions, heavy metals and other toxic substances exceeding the standard, and achieve the effect of avoiding the sticky zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Measure out 1000ml of raw sludge at room temperature, add 30g and 100g of fly ash respectively, and then add an appropriate amount of heavy metal stabilizer. The heavy metal stabilizer is composed of iron oxide, aluminum oxide, activated carbon and sodium phosphate in solid phase. Mix and stir for 20 minutes. , the pH is controlled at 11, and after washing, pressing and drying, a mixture of fly ash and sludge can be obtained.

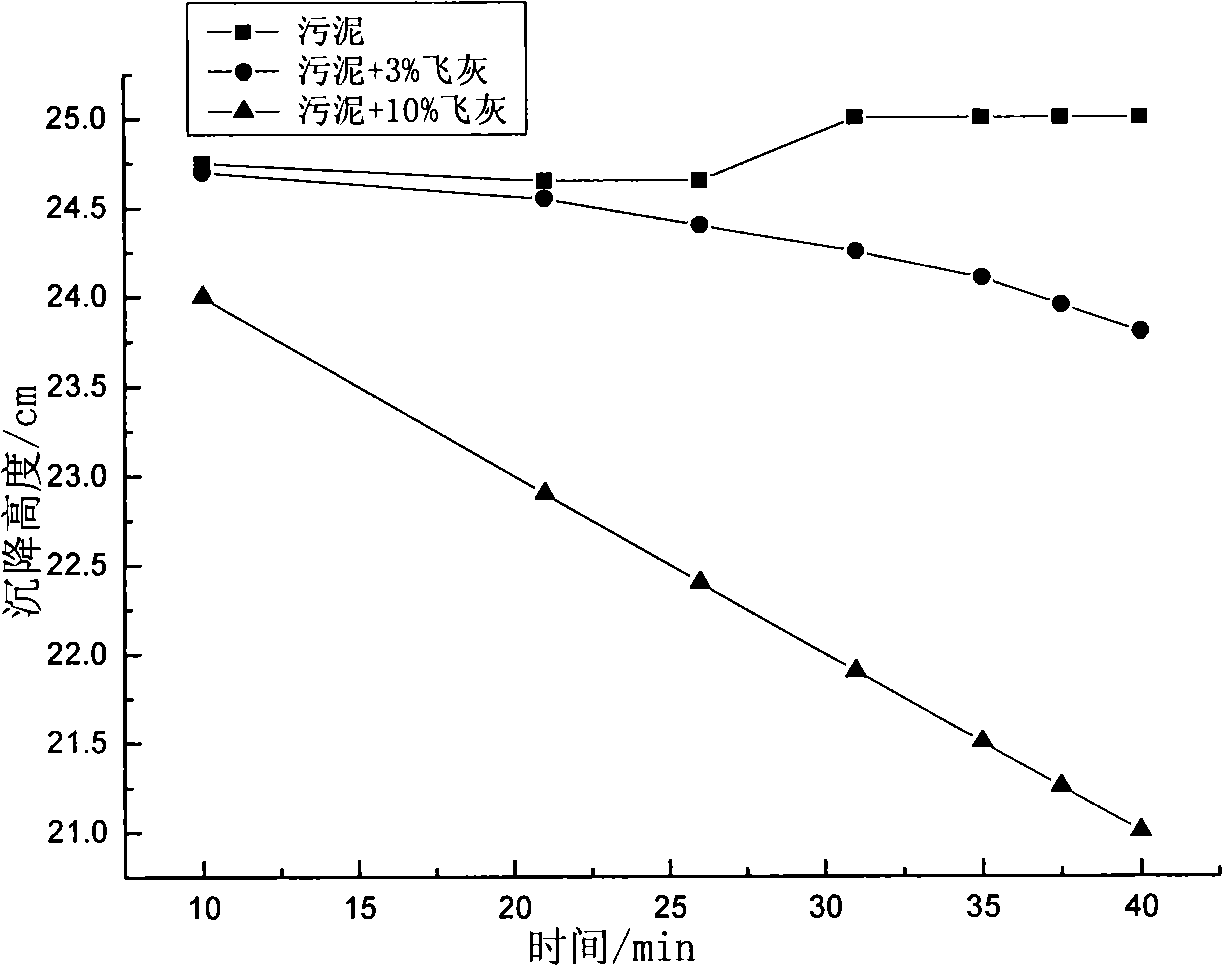

[0017] Fly ash has a great influence on the sedimentation performance and dewatering performance of sludge. The sludge without fly ash will expand after a period of time, and the water content will be reduced from 97% to 83% after a certain pressure filtration process; adding 3 The sludge with 10% and 10% fly ash has a certain improvement on the settling performance and the dehydration performance is greatly improved, and the moisture content of the mixture can be reduced to 60-75% after dehydration.

[0018] After stirring, the fly ash / sludge mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com