Monitoring system for wire rope tension balancing cylinder and lifting load

A technology for balancing oil cylinders and monitoring systems, which is applied to elevators, lifting equipment in mines, transportation and packaging, etc., can solve problems such as hidden safety hazards and difficulty in maintaining the tension balance oil cylinder of hoist wire ropes, to prevent rope breakage and solve monitoring problems. Problems, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

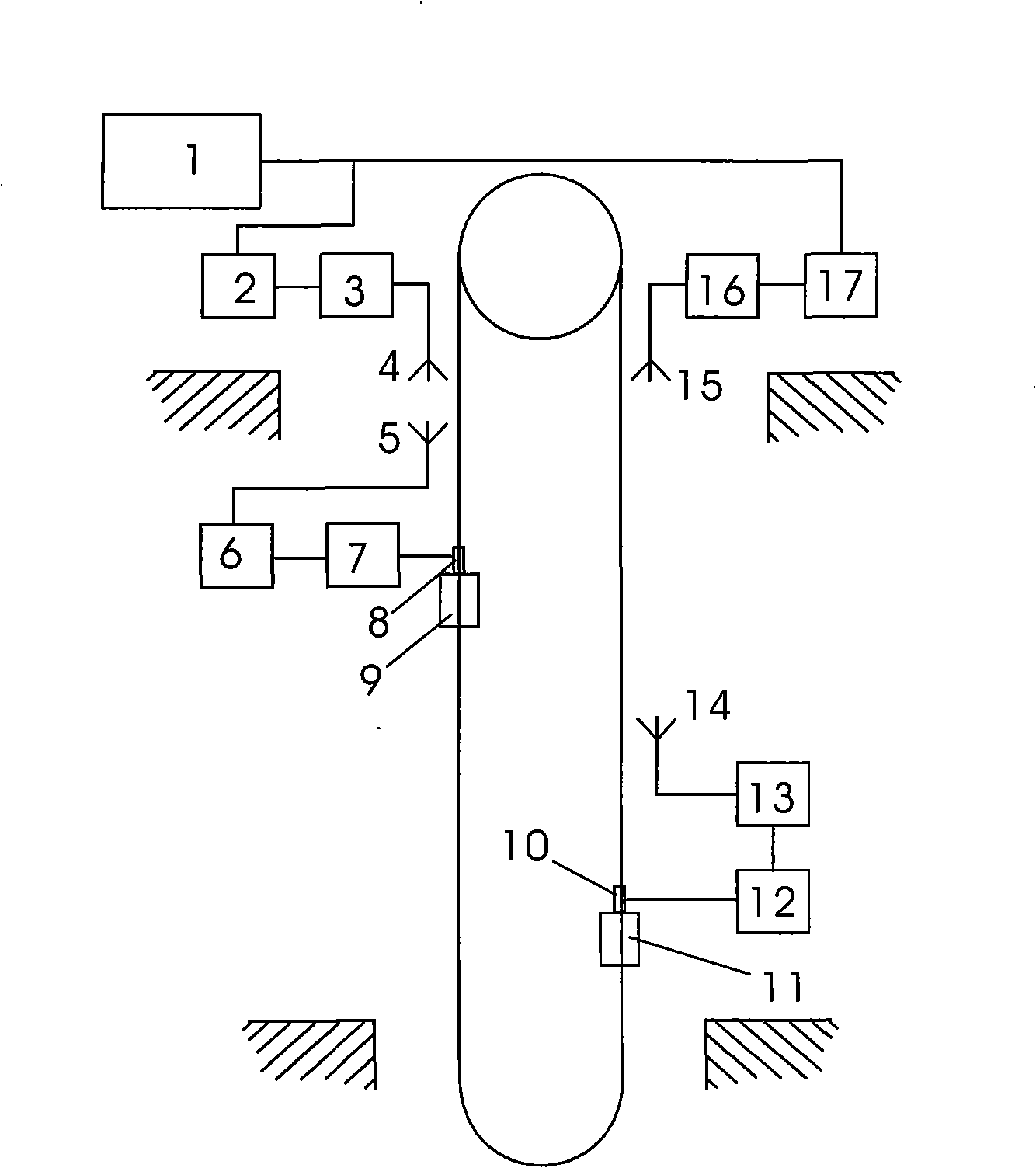

[0011] Now refer to the attached figure 1 , are described as follows in conjunction with the embodiments: the steel wire rope tension balance oil cylinder position and lifting load monitoring system according to the present invention involves a monitoring host computer 1, a main controller A2, a wireless signal receiver A3, a signal receiving antenna A4, and a signal transmitting antenna A5 , wireless signal transmitter A6, signal processor A7, displacement hydraulic sensor A8, lifting container A9, displacement hydraulic sensor B10, lifting container B11, signal processor B12, wireless signal transmitter B13, signal transmitting antenna B14, signal receiving antenna B15 , wireless signal receiver B16 and main controller B17. The main monitoring computer 1 is connected in parallel with the main controller A2 and the main controller B17, the main controller A2 is connected with a wireless signal receiver A3, and the wireless signal receiver A3 is connected with a signal receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com