Planar automatic displacement control device

A technology of displacement control and control device, which is applied in the direction of conveyor control device, escalator, transportation and packaging, etc. It can solve the problems of no automatic displacement device, etc., and achieve the effect of high degree of automation, improved automation level and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

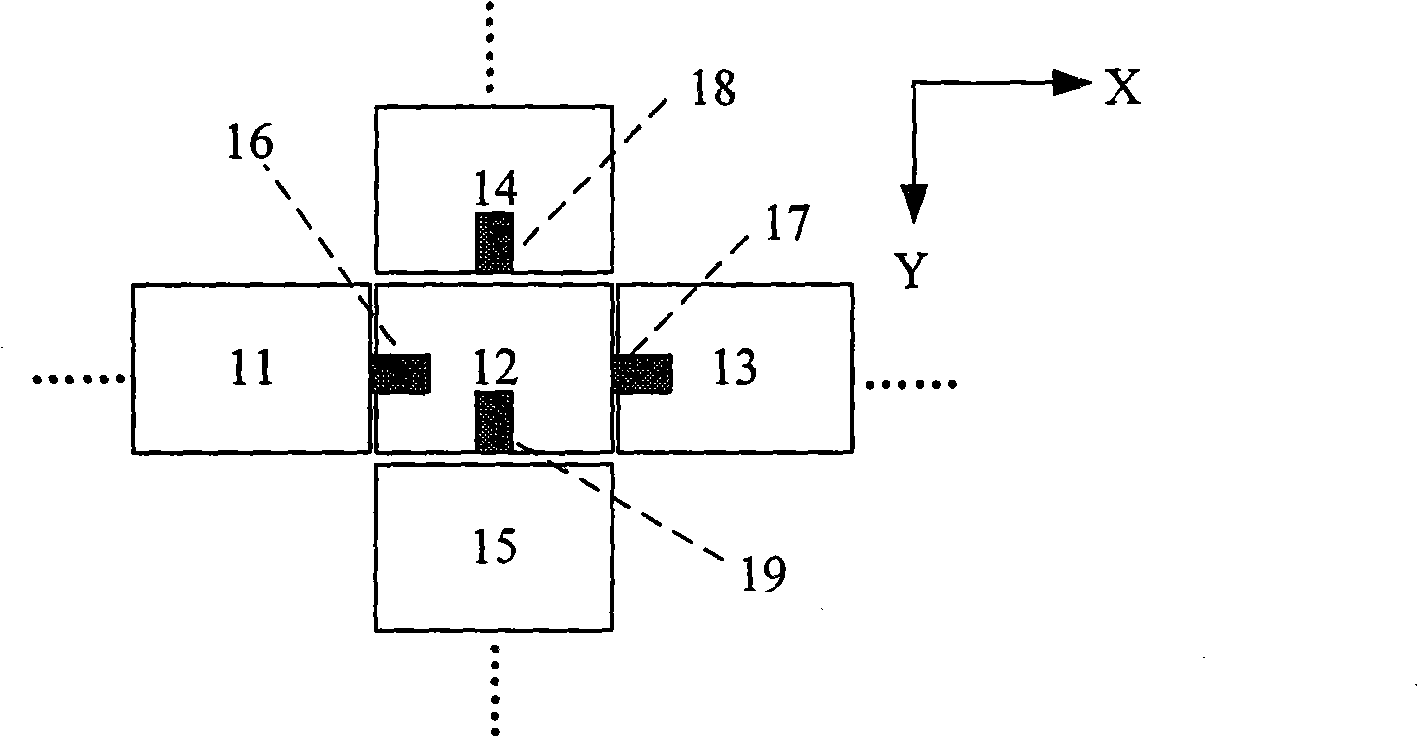

[0018] like figure 1 , 2 As shown, in the horizontal plane, the two conveyor belt systems are perpendicular to each other and placed in a cross-shaped angle, that is, placed in the X and Y directions, where the outer conveyor belt system x includes the inner conveyor belt system y inside. The two conveyor belt systems are composed of a driving device and a transmission device respectively. The driving device includes a motor and two supporting wheels driven by the motor, one of which is a driving pulley and the other is a driven pulley. The power generated by the motor can drive the supporting wheel to run. The supporting wheel drives the conveying device wound on it to generate cyclic displacement. The conveyor belt of the conveyor consists of a set of conveyor blocks of the same size and connectors between the conveyor blocks. The size of the teleport block is determined by the size of the axle in the respective direction. Two conveyor belt systems always have an overlapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com