Coating technique of edge sealing strip with high brightness and highly wear resistant and equipment thereof

A technology of coating equipment and coating process, which is applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc., can solve problems such as inability to achieve, poor brightness of edge strips, affecting the surface finish of edge strips, etc. , to achieve the effect of improving flatness and smoothness, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The coating process of high-brightness and high wear-resistant edge banding is as follows: the first step is to preheat the prepared edge banding substrate; the second step is to enter the preheated substrate through the conveyor belt In the coating chamber of the coating equipment, in the coating chamber after vacuum and static elimination, the substrate is first coated with a layer of UV varnish by the coating rubber roller rotating clockwise, and then coated by the coating roller rotating counterclockwise The cloth rubber roller is coated with another layer of UV varnish.

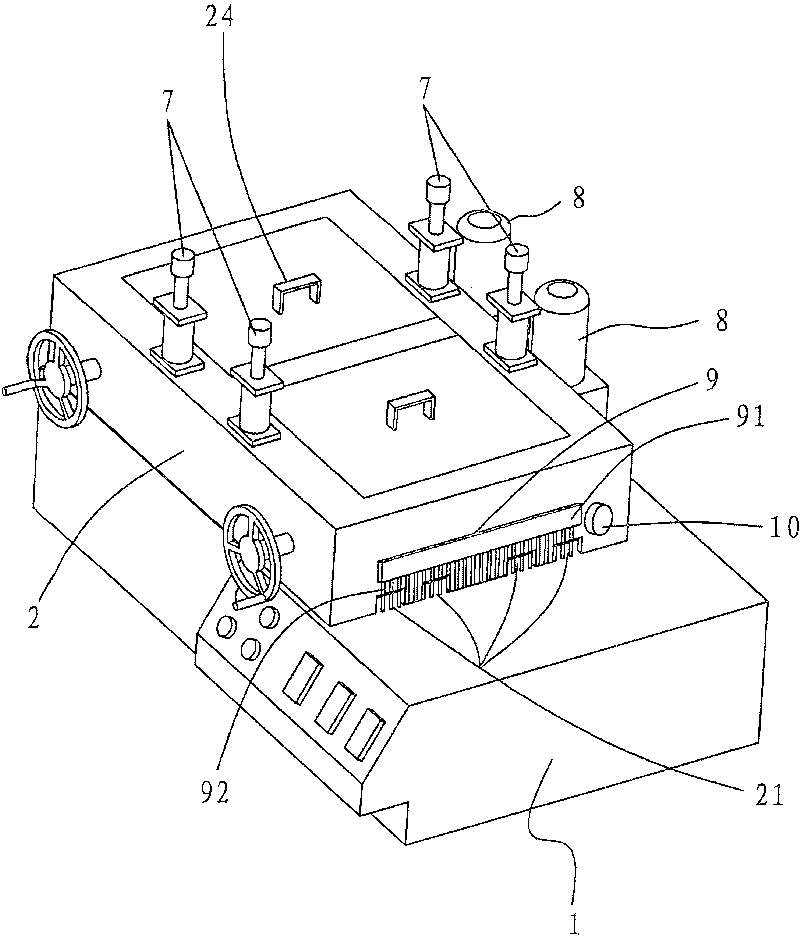

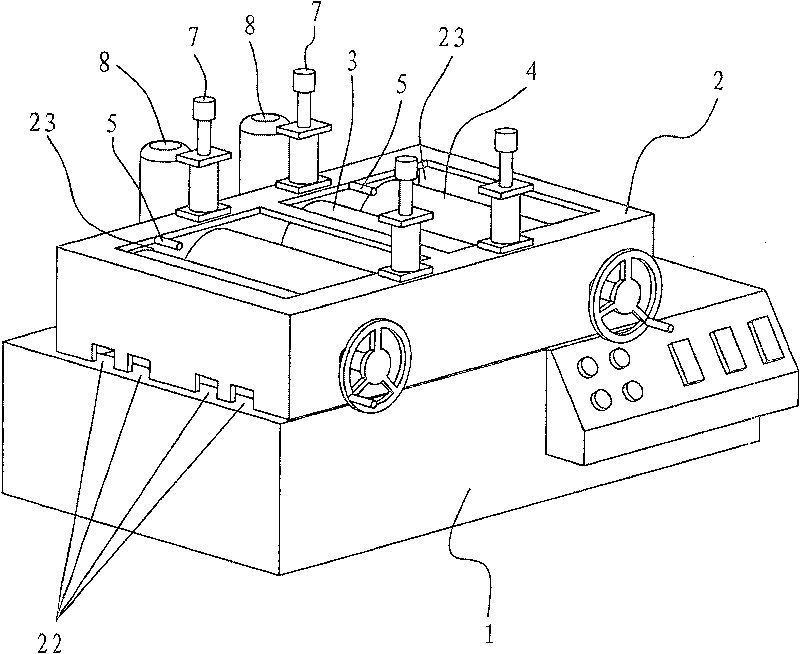

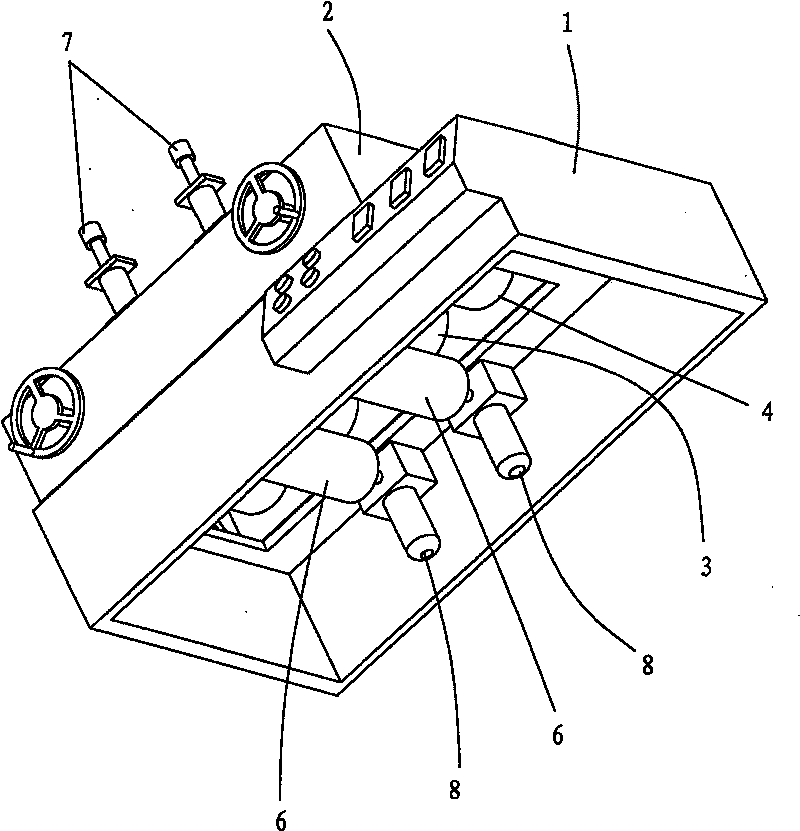

[0015] See figure 1 , 2 , 3, the coating equipment for coating high-brightness, high-wear-resistant edge banding includes a box body 1 and a coating chamber 2, the coating chamber 2 is arranged on the box body 1, and the coating chamber 2 is equipped with There are two coating rubber rollers 3, and each coating rubber roller 3 is equipped with a fixed amount roller 4, and the gap between the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com