Mixed field excitation type flux switch motor

A magnetic flux switching motor and hybrid excitation technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of competitive discount, complex motor structure, etc., and achieve easy development, high power density, and large torque output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

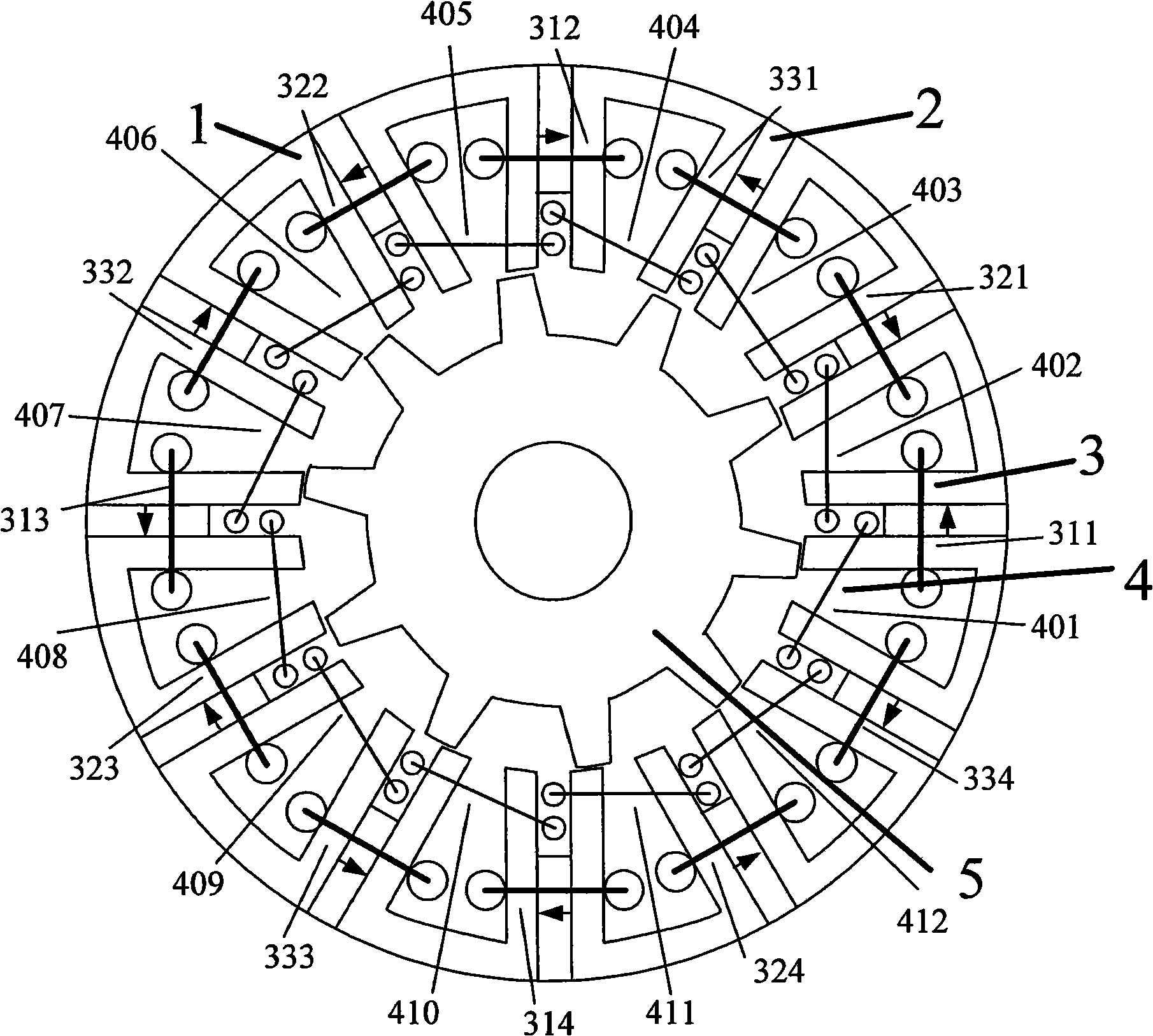

[0015] Such as figure 1 As shown, the hybrid excitation type magnetic flux switching motor of the present invention includes a stator core 1 and a rotor core 5, the rotor 5 is located inside the stator 1, both the stator 1 and the rotor 5 are salient pole structures, and the stator core part is composed of 12 U-shaped guides. Composed of a magnetic core, the stator 1 is provided with a three-phase concentrated winding 3, a single-phase excitation winding 4 and 12 permanent magnets 2;

[0016] The A-phase first winding coil 311 and the third winding coil 313 of the concentrated winding 3 are diametrically opposite, the second winding coil 312 and the fourth winding coil 314 are diametrically opposite, and each winding coil is sleeved in two adjacent winding coils in the stator 1 In the slot of the U-shaped iron core, and the above four winding coils are sequentially connected end to end in series; a permanent magnet 2 is arranged between two adjacent U-shaped magnetic conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com