Method for preparing thin type press key panel

A manufacturing method and thinning technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as increased steps or procedures, increased man-hours, increased button thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings:

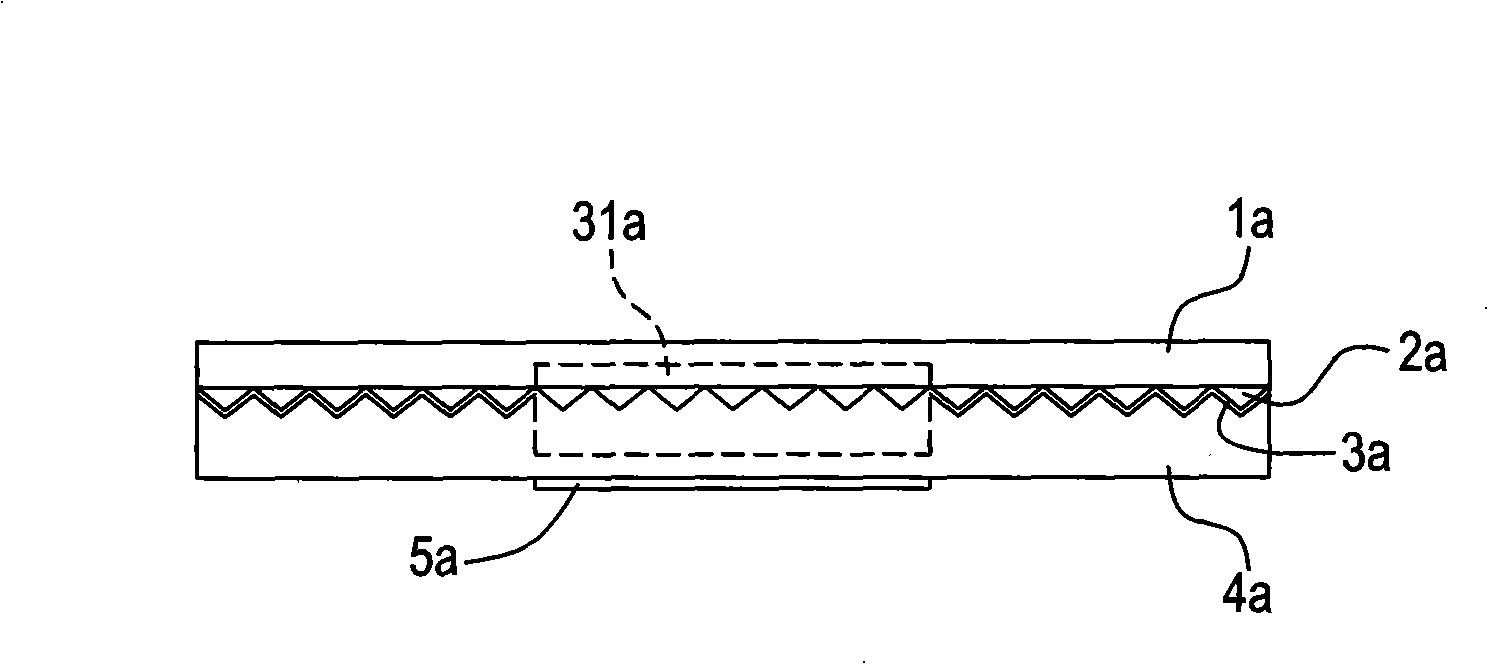

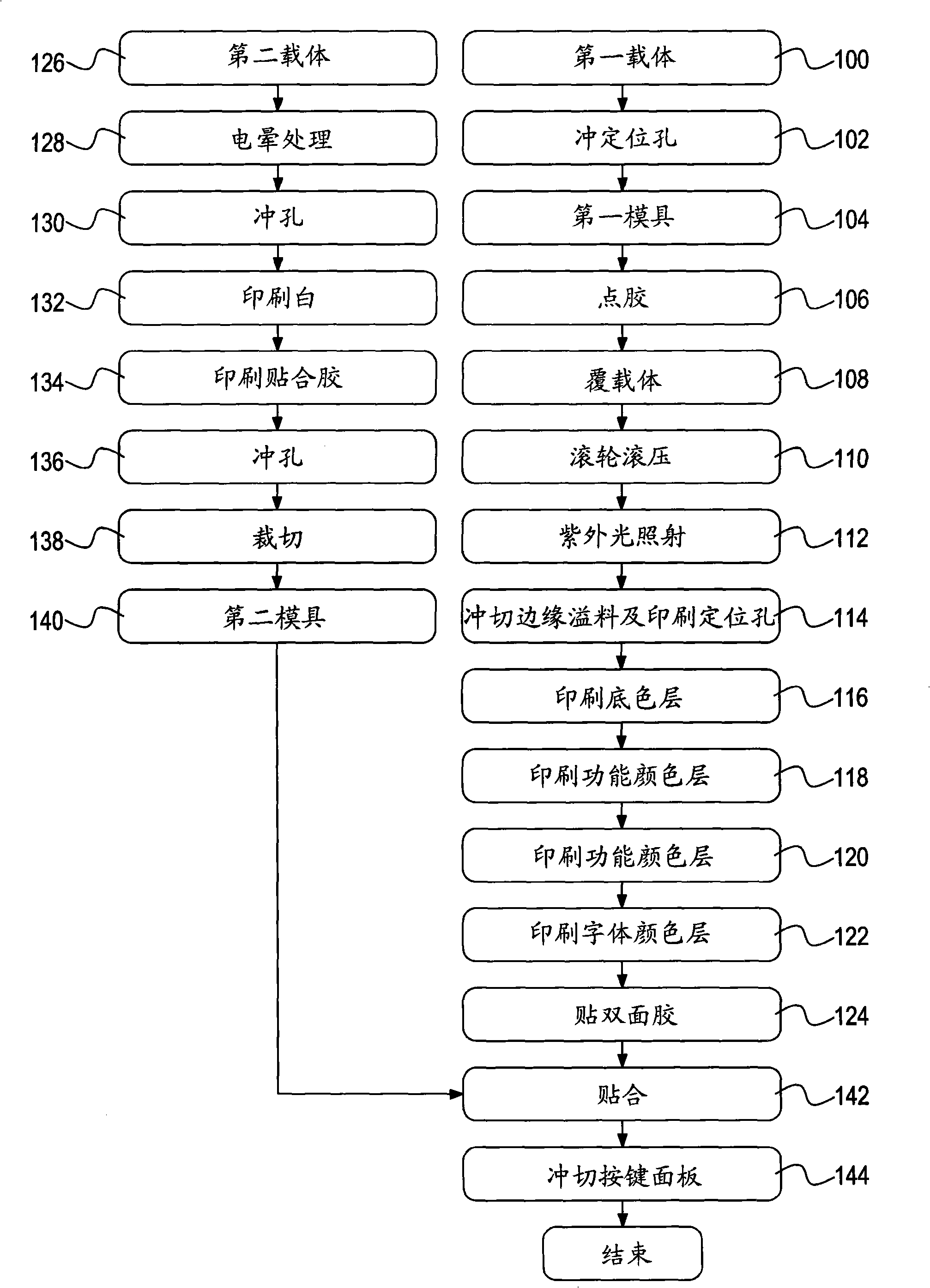

[0038] See Figure 2A , Is a schematic diagram of the manufacturing process of the first thin button of the present invention. The figure discloses a method for manufacturing a button structure with a pattern layer button. First, as in step 100, a carrier 2 made of a transparent material of a polycarbonate film (PC Film) is prepared.

[0039] Step 102, please refer to image 3 , Punch a positioning hole 21 on the surface of the first carrier 2, and the positioning hole 21 is used to provide the first carrier 2 to be positioned on the positioning post 13 of the first mold 1.

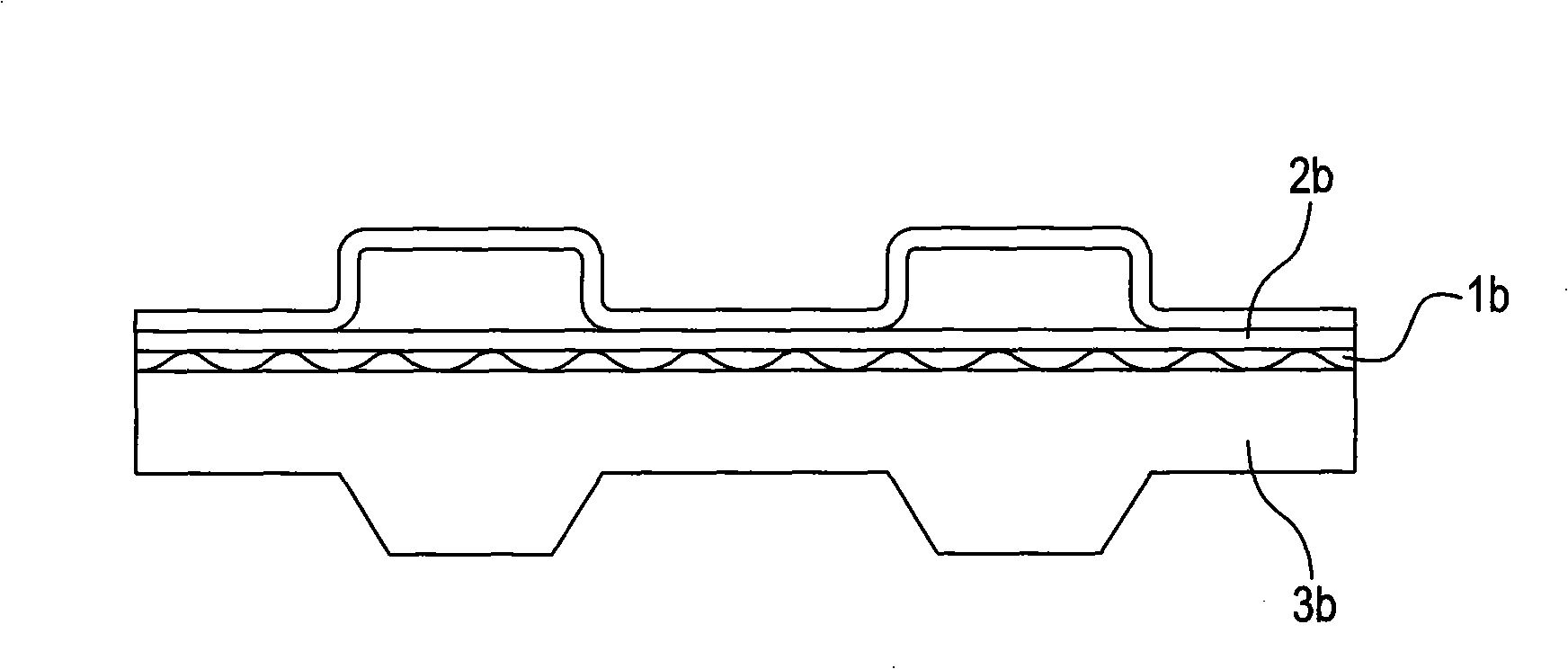

[0040] Step 104, please refer to Figure 4 , Equipped with a first mold 1, in the first mold 1 has a first mold cavity 11, the first mold cavity 11 has a plurality of second mold cavities 12, the second mold cavity 12 is used to shape the shape of the button, and The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com