Method for processing acid mud in chimney smelting flue gas

A treatment method and technology for smelting flue gas, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of safety and environmental protection hidden dangers in production sites, corrosion of chimney liner, blocked pipes, etc. Achieve the effect of eliminating hidden safety and environmental protection hazards, solving pipeline acid accumulation, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

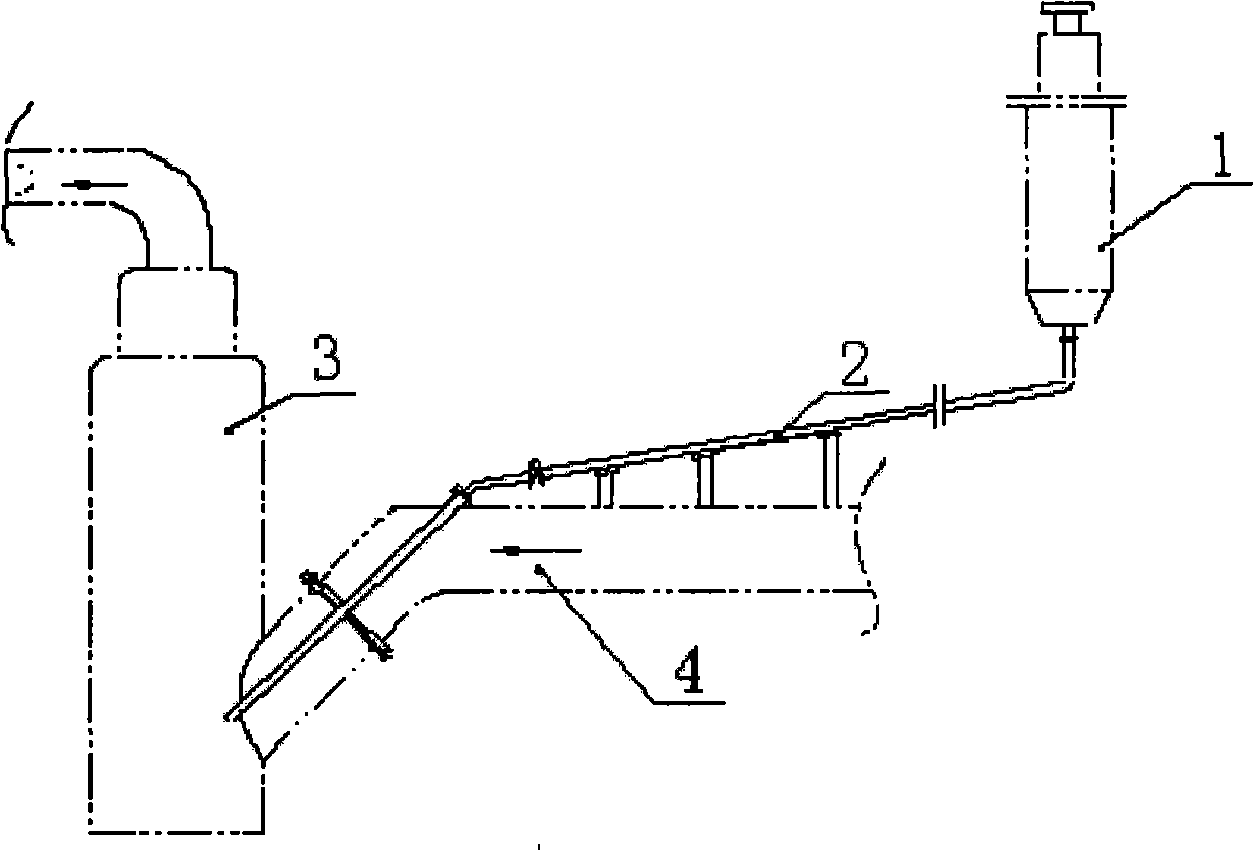

[0011] Connect the inclined pipe at the bottom of the smelting flue gas chimney, and directly enter the drying tower by adding a socket on the FRP pipe. The inclined pipe is made of CPVC, and the acid mud has good fluidity in it; the tail gas chimney and the drying tower form a certain pressure Poor, it is conducive to the flow of acid mud, use DN200CPVC (chlorinated polyvinyl chloride) pipe, enter the drying tower from the bottom of the chimney, install a butterfly valve before entering the tower to prevent excessive air leakage. The acid sludge is discharged into the drying tower for disposal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com