Method for covering aluminum oxide coating on honeycomb shaped wire mesh carrier

A technology of honeycomb metal and aluminum oxide coating, which is applied in the direction of chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst carriers, etc. The layer preparation process is complicated and other problems, and the process is simple, and the effect of improving thermal shock resistance and mechanical vibration resistance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

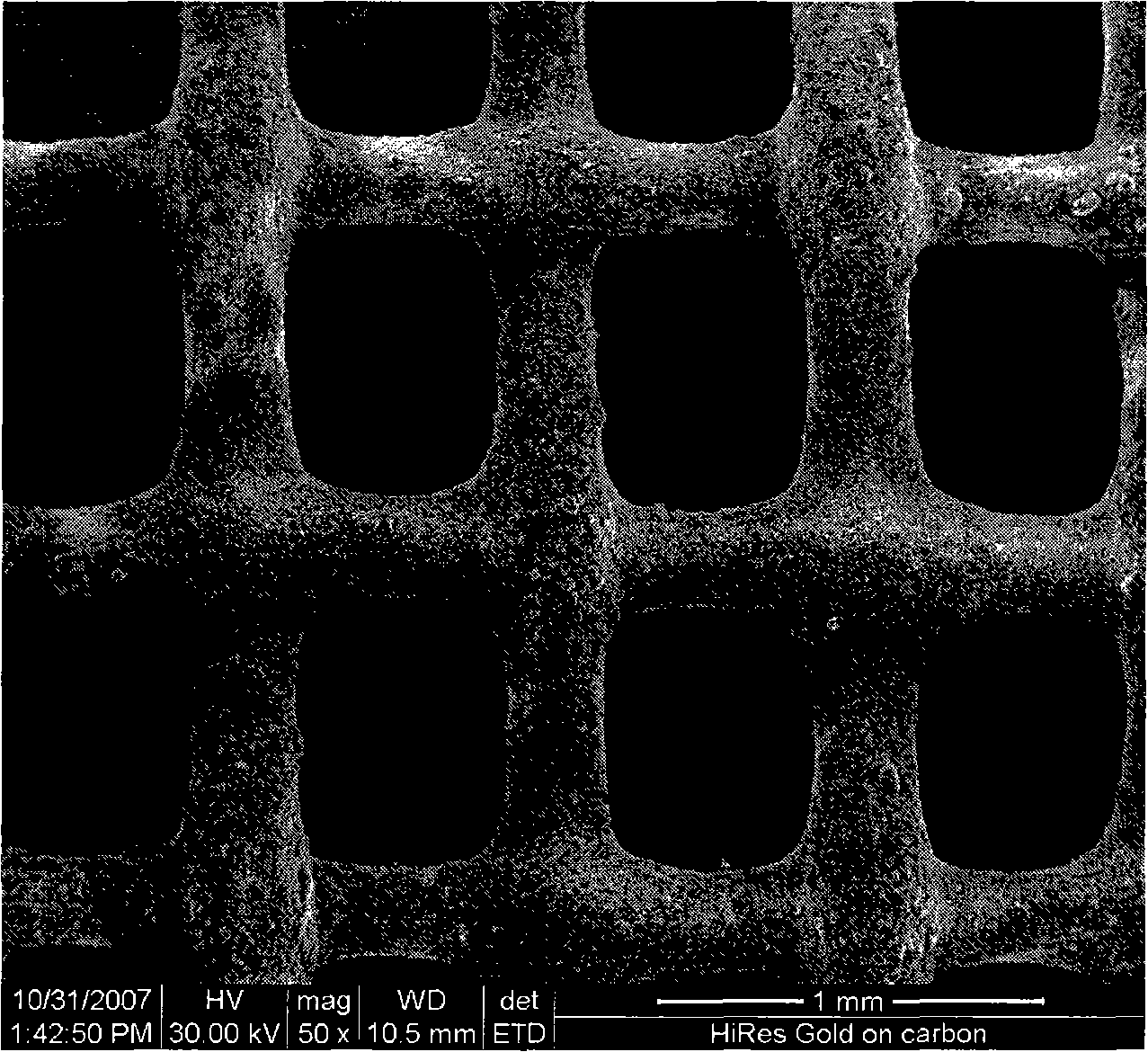

[0035] Embodiment 1: select the honeycomb carrier specification of the aluminum-containing stainless steel wire mesh (30 orders, wire diameter 0.3mm) of 0Fe25Cr5Al to be

[0036] In the first step, the honeycomb wire mesh carrier is immersed in 10% sulfuric acid solution, soaked for 5 minutes under ultrasonic conditions, rinsed with deionized water after taking it out, and then dried at 100°C for 5 hours;

[0037] In the second step, add 8g of γ-Al to 184ml of absolute ethanol which is constantly stirring 2 o 3 powder (5-10μm in particle size) and 0.8g aluminum powder (4-5μm in particle size), then add 4ml of 1.016g / L polyacrylic acid ethanol solution and 12ml of 3g / L aluminum isopropoxide ethanol solution, the total volume of the slurry 200ml. After stirring for 30 minutes, sonicate in an ultrasonic oscillator for 30 minutes;

[0038] The third step is to apply a voltage of 10V to the slurry for 5h while stirring, and the electrodes used are stainless steel electrodes; ...

Embodiment 2

[0042] Embodiment 2: select the aluminum-containing stainless steel wire mesh (30 orders, wire diameter 0.3mm) of 0Fe25Cr5Al for use. The honeycomb carrier specification is

[0043] In the first step, the honeycomb wire mesh carrier is immersed in a sulfuric acid solution, soaked for 5 minutes under ultrasonic conditions, rinsed with deionized water after taking it out, and then dried at 100°C for 8 hours;

[0044] In the second step, add 8g of γ-Al to 184ml of absolute ethanol which is constantly stirring 2 o 3 powder (5-10μm in particle size) and 2.0g aluminum powder (4-5μm in particle size), then add 4ml of 1.016g / L polyacrylic acid ethanol solution and 12ml of 3g / L aluminum isopropoxide ethanol solution, the total volume of the slurry 200ml. After stirring for 30 minutes, sonicate in an ultrasonic oscillator for 30 minutes;

[0045] The third step is to apply a voltage of 20V to the slurry for 5h while stirring, and the electrodes used are stainless steel electrodes; ...

Embodiment 3

[0049] Embodiment 3: select the aluminum-containing stainless steel wire mesh (30 orders, wire diameter 0.3mm) of 0Fe25Cr5Al for use. The honeycomb carrier specification is

[0050] In the first step, the honeycomb wire mesh carrier is immersed in sulfuric acid solution, soaked under ultrasonic conditions for 10 minutes, taken out, rinsed with deionized water, and then dried at 100°C for 8 hours;

[0051] In the second step, add 8.0g of γ-Al to 184ml of absolute ethanol which is constantly stirring 2 o 3 powder (5-10 μm in particle size) and 8.0 g of aluminum powder (4-5 μm in particle size), then add 4 ml of 1.016 g / L polyacrylic acid ethanol solution and 12 ml of 3 g / L aluminum isopropoxide ethanol solution, the total amount of slurry The volume is 200ml. After stirring for 30 minutes, sonicate in an ultrasonic oscillator for 30 minutes;

[0052] The third step is to add 10V voltage to the slurry for 5 hours while stirring, and the electrodes used are stainless steel el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com