Reflector lamp

A reflective lamp and reflective coating technology, which is applied in the direction of incandescent lamps, incandescent lamp parts, gas discharge lamp parts, etc., can solve the problems of high cost, high reflectivity, complex coating process of reflector lamps, etc., to prevent Effect of base side overheating, high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

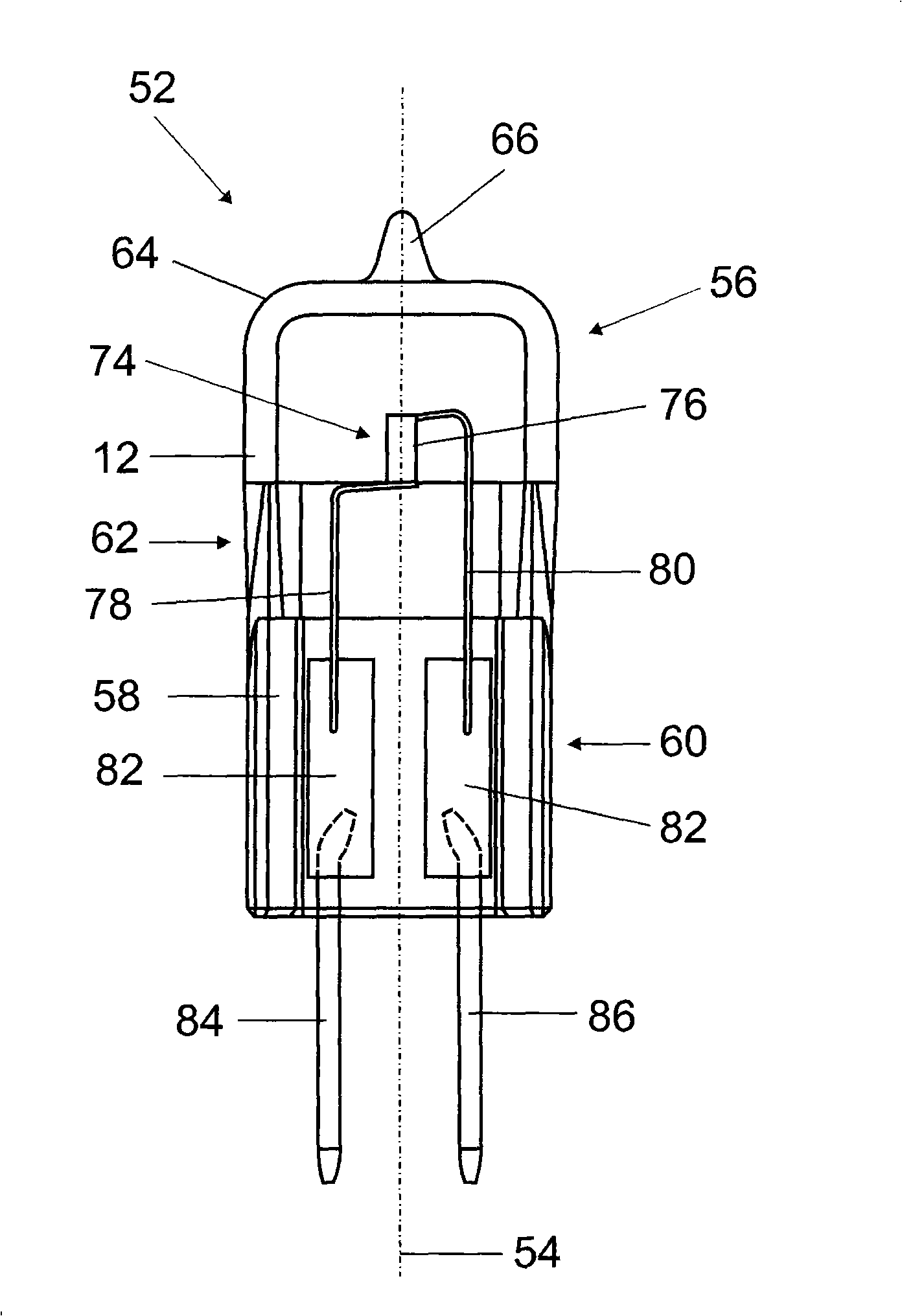

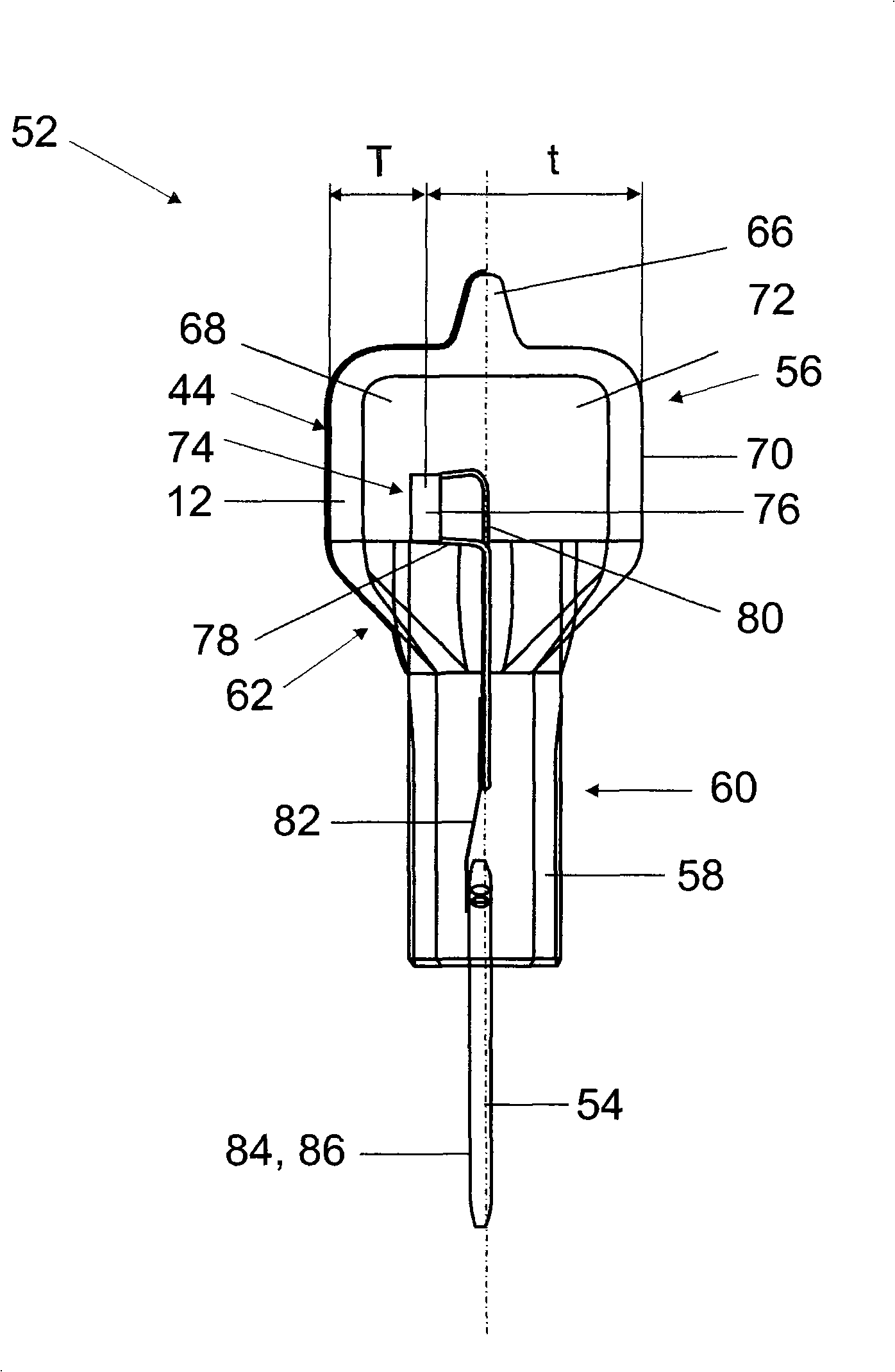

[0031] The invention is explained below with reference to halogen reflector lamps using low-voltage technology with lamp sockets on one side, which are used in large numbers, for example, in general lighting. However, as mentioned at the outset, the reflector lamp according to the invention is by no means limited to this lamp type.

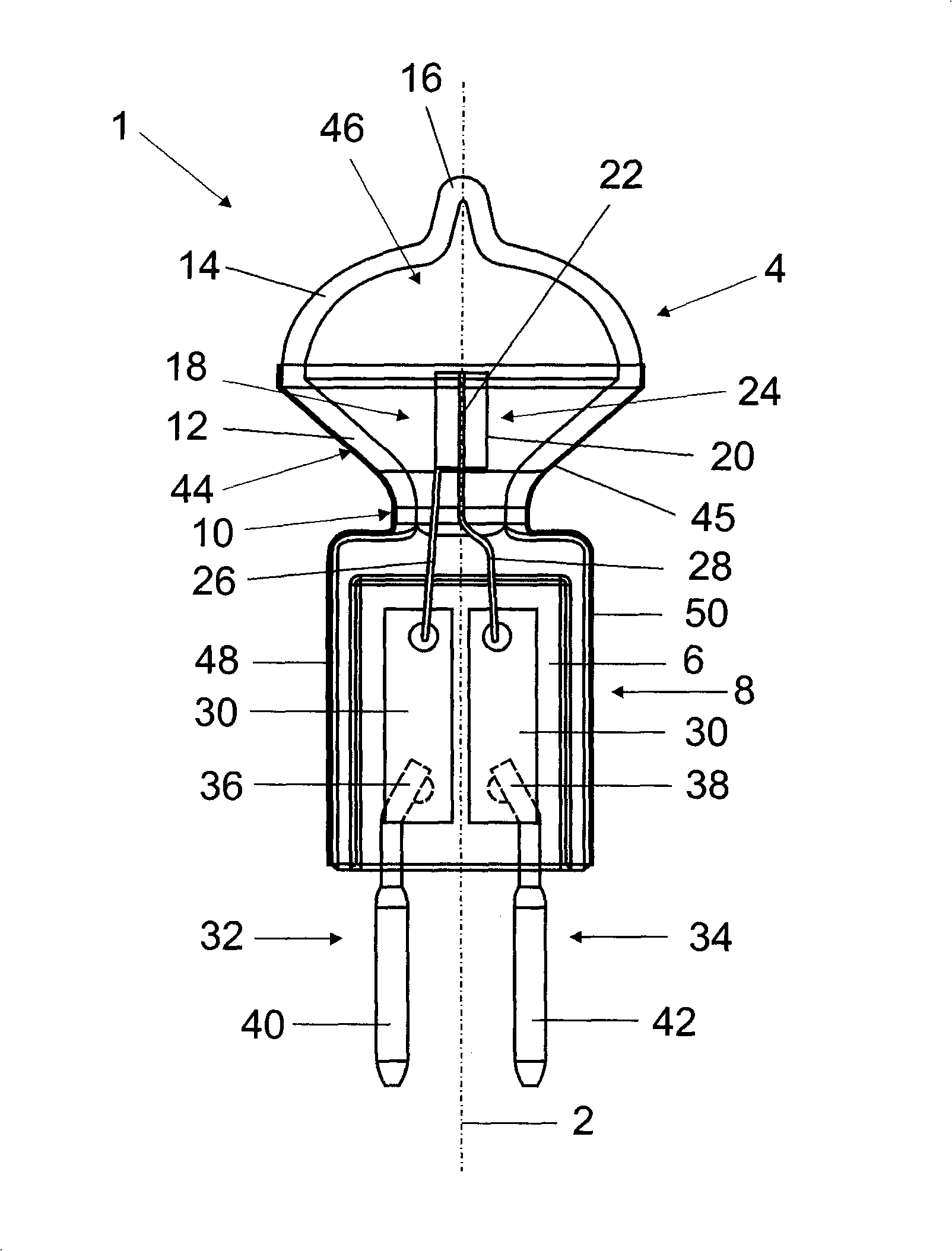

[0032] with the help of figure 1 First, a first exemplary embodiment of a reflector lamp according to the invention with an axial reflector is explained.

[0033] figure 1 Shown is a reflector lamp in the form of a low-pressure halogen reflector lamp 1 with a lamp vessel 4 made of quartz glass that is rotationally symmetrical about the lamp longitudinal axis 2 , in the lamp vessel 4 ( figure 1Middle) on the lower end section, a base 8 of type GY6.35 is formed via a shrink cap 6 , via which the halogen reflector lamp 1 can be inserted into a lampholder, not shown. The shrink cap 6 transitions via an approximately cylindrical lamp neck 10 into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com