Auxiliary robot for wireless detecting and controlling assembly line product manufacture

A product manufacturing and assembly line technology, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve the problems of product quality hidden dangers and the inability to actually understand the nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be described below according to the accompanying drawings

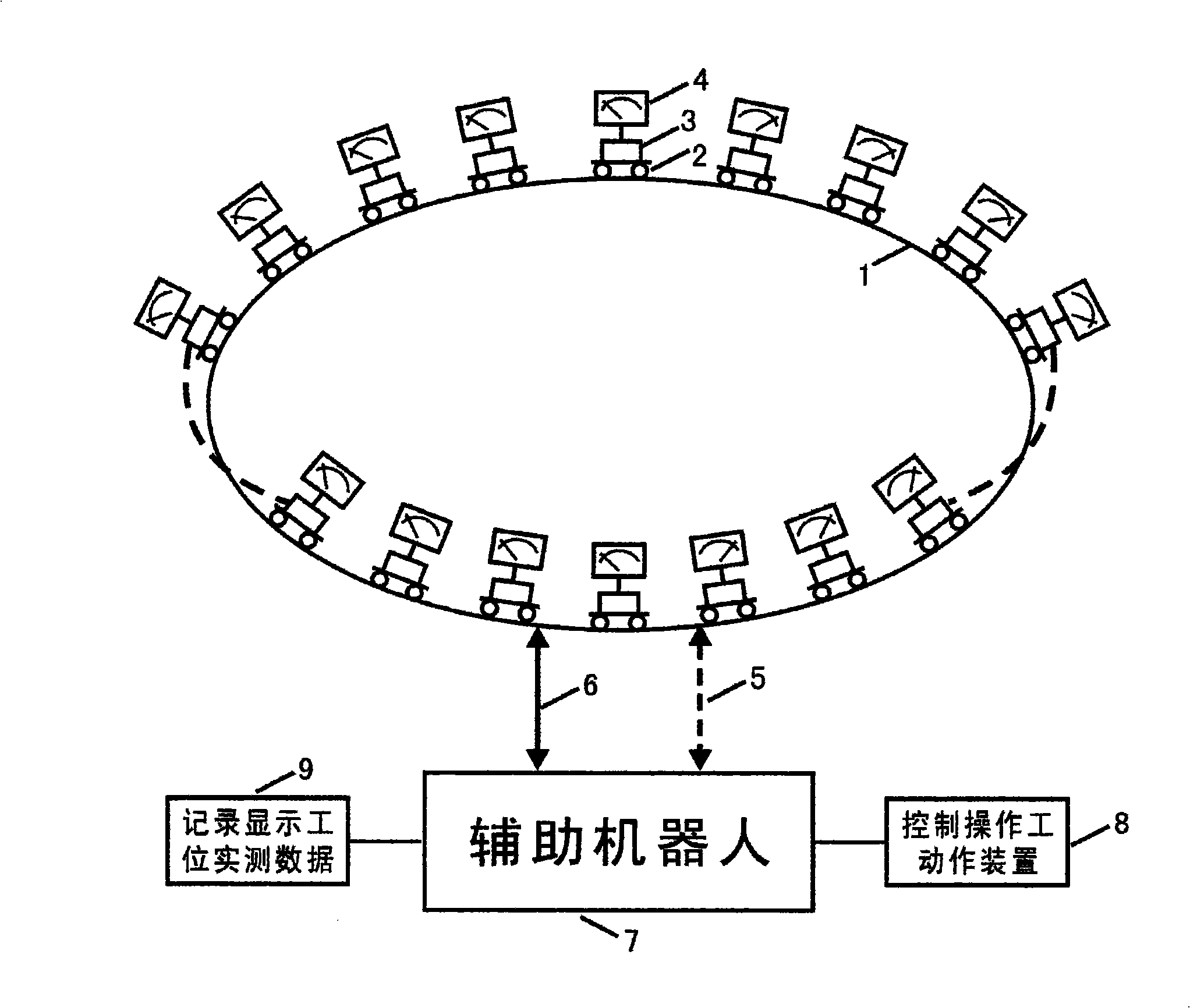

[0022] Such as figure 1 Shown is an assisting robot system according to the present invention, which is formed as follows. Reference number 1 is the track of the entire assembly line. Generally, there are more than 40 stations. Reference number 2 is a station trolley. The trolley is a 4-wheel rail car. The upper part of the rail car is the assembly line product platform. Reference number 3 is large-scale Production of assembly line products, such as: automobiles, washing machines, refrigerators, air conditioners, electric motors, televisions, etc. Reference number 4 is equipment such as sensors for detecting products, wireless transmitting and receiving devices for microelectronic controllers, and the like. Reference number 5 is a wireless signal medium, and its medium can be infrared rays, electromagnetic waves, lasers, etc. Reference number 6 is the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com