Biomass shaping fuel decoupling combustion device and combustion method thereof

A technology of briquetting fuel and combustion device, which is applied in the field of biomass briquetting fuel decoupling combustion device and its combustion, can solve the problems of weak combustion of volatile matter and semi-coke, high requirements on fuel fluidity, unfavorable semi-coke burnout, etc. , to achieve the effect of reducing the coupling relationship, reducing the pollutant content and improving the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

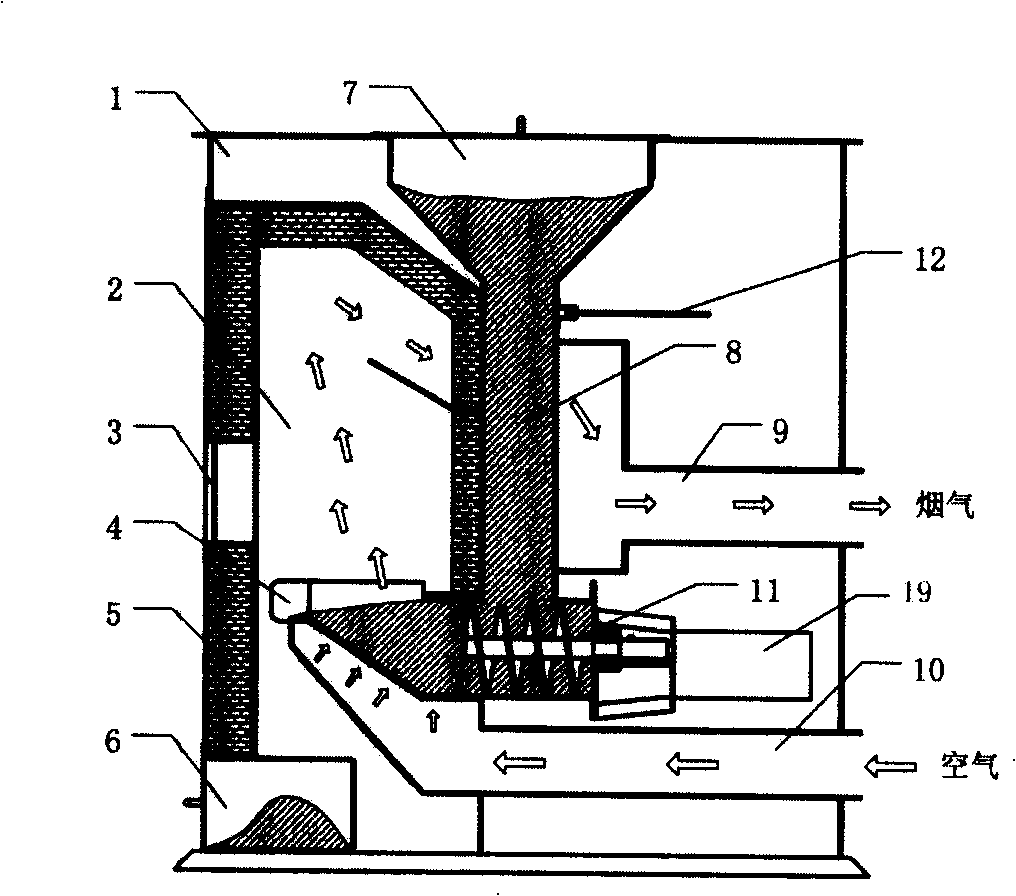

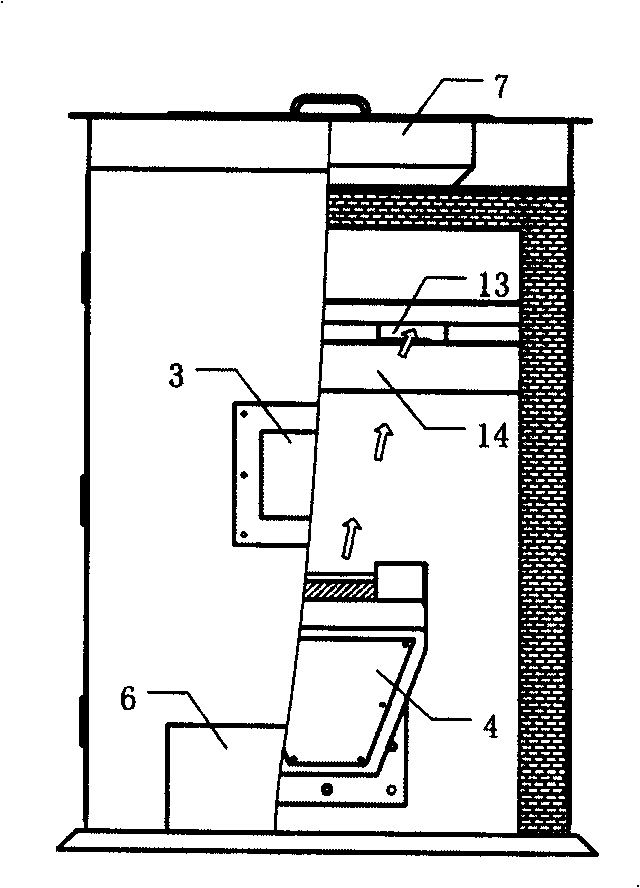

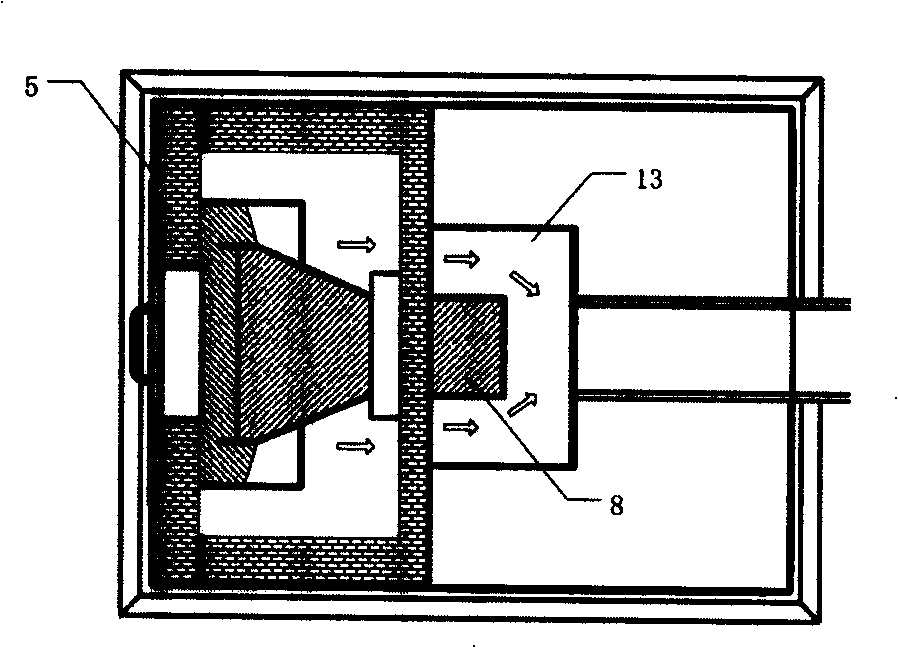

[0043] The biomass briquette fuel decoupling combustion device of this embodiment, as shown in Figure 1, includes: a vertical combustion furnace 1, a hopper 7 is arranged above the furnace body, and the lower part of the hopper 7 is connected to a pyrolysis chamber 8 with a rectangular cross section , the bottom of the pyrolysis chamber 8 is provided with a screw conveyor 11, and the lower part of the pyrolysis chamber communicates with the lower part of the combustion chamber 2, the combustion chamber 2 is adjacent to the pyrolysis chamber 8, and the lower part of the combustion chamber 2 is provided with Fire grate 4, an air duct 10 is provided below the fire grate 4, and the screw conveyor 11 transports the biomass molding fuel pyrolyzed in the pyrolysis chamber 8 to the fire grate 4, as shown in Figure 1, the combustion A flue gas deflector 14 is arranged above the interior of the chamber 2, and the upper part of the flue gas deflector 14 communicates with the flue gas inte...

Embodiment 2

[0051] The method for burning using the biomass briquette fuel decoupling combustion device in embodiment 1 comprises the steps:

[0052] (1) Biomass molding fuel enters the pyrolysis chamber 8 from the hopper 7, and the temperature in the pyrolysis chamber 8 can reach 300-800 °C by utilizing the heat in the combustion chamber 2 and the waste heat of the flue gas flowing through the flue gas interlayer 13 outside the pyrolysis chamber 8 °C, the biomass briquettes in the pyrolysis chamber 8 are slowly pyrolyzed under low temperature and oxygen-free conditions to generate volatiles and semi-coke;

[0053] (2) The biomass semi-coke produced by pyrolysis enters the upper surface 15 of the fire grate 4 under the conveyance of the screw conveyor 11, and contacts with the air sent in from the air chamber 17 below the fire grate 4 and the side air supply port 16 Combustion begins after the pyrolysis, and when the volatile matter generated by pyrolysis enters the combustion chamber 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com