Spacing telescoping mechanism using inverse parallelogram

A technology of anti-parallelogram and telescopic mechanism, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of high manufacturing process requirements, limited expansion range, and small application range, and achieve simple manufacturing process and large expansion range , the effect of simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with accompanying drawings.

[0026] The space telescopic mechanism utilizing the antiparallelogram is composed of multiple component units stacked in series, and each component unit includes upper and lower layers of intermediate frames. Figure 9 It is a schematic diagram of a space expansion and contraction mechanism using antiparallelogram formed by connecting two component units in series.

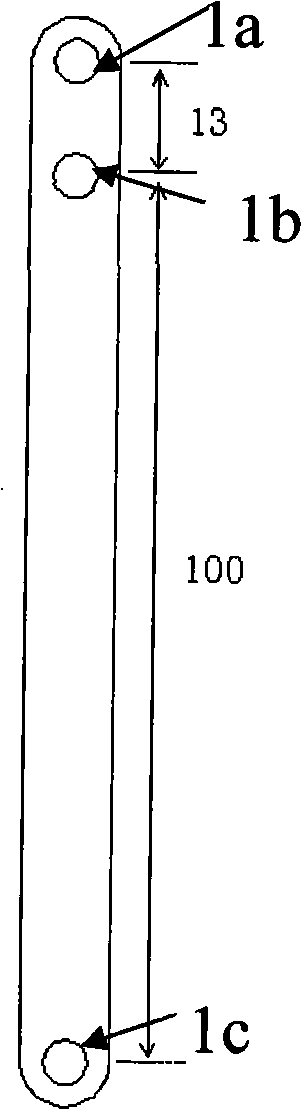

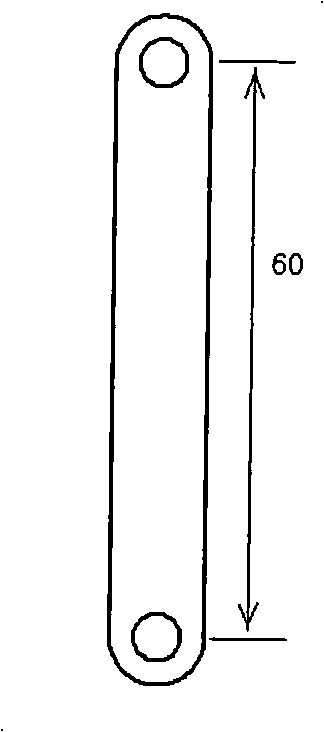

[0027] The first type of module unit, see figure 1 :

[0028] The upper intermediate frame is composed of three intermediate frame rods 6 connected end to end with pins, and each connected with the first rod 1 at the end and end joints, see figure 1 .

[0029] The lower intermediate frame is composed of three intermediate frame rods 6 connected end to end with pins, and connected with the third rod 3 at the end and end joints, see figure 1 .

[0030] A hole is respectively established at both ends of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com