Film and method of making film

A technology of blown film and cast film, applied in the field of film and its manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

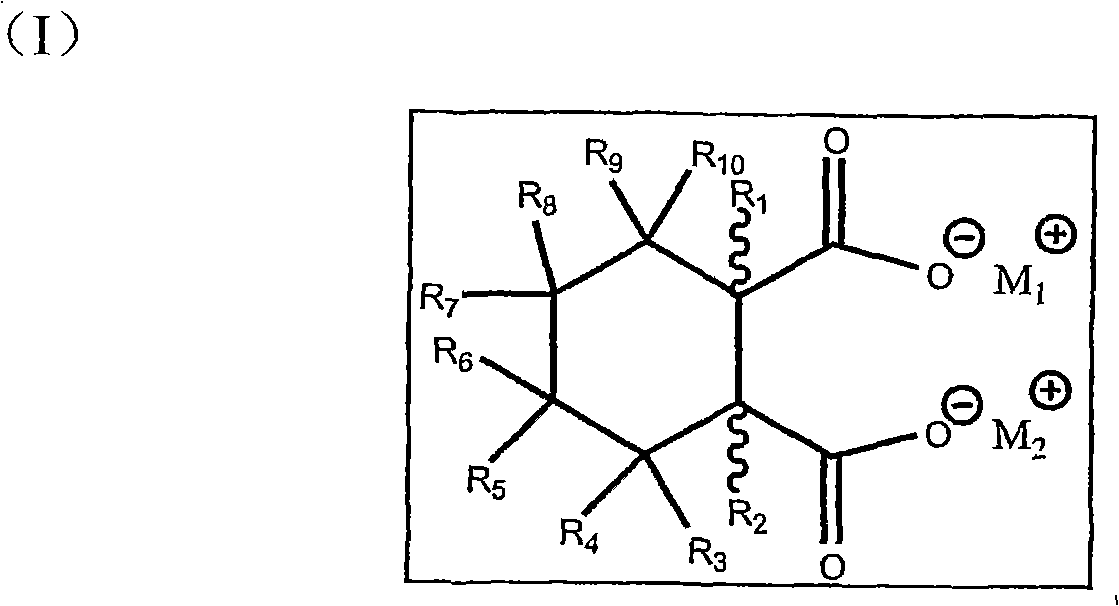

[0053] Calcium HHPA in LLDPE

[0054] To a linear low density polyethylene (LLDPE) common in the film industry with a density of 0.917 g / cm3 was applied 1000 ppm of the following mixture of HHPA calcium compounds:

[0055]

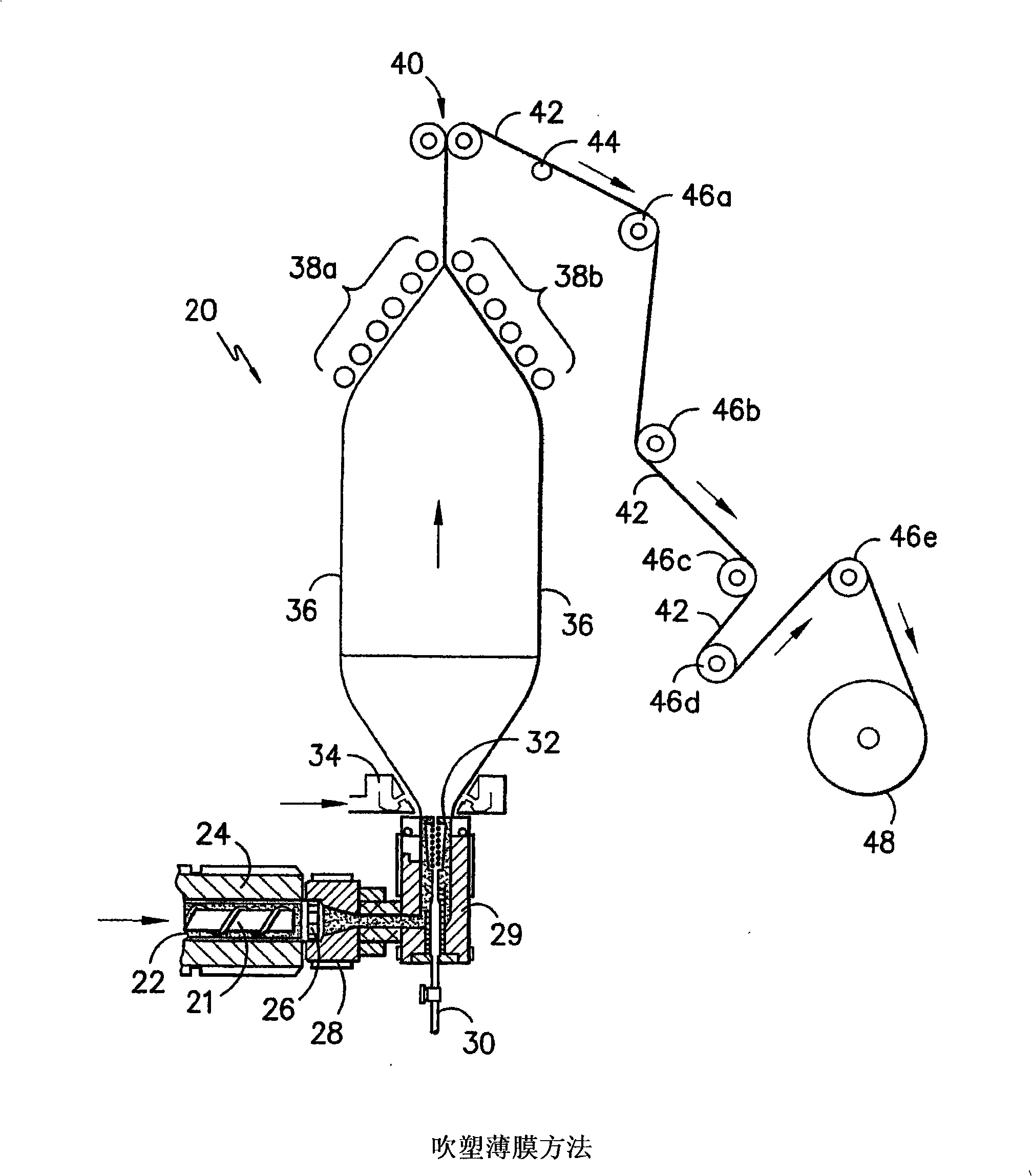

[0056] Also add above-mentioned compound and standard stabilizing package (500ppm 1010, 1000ppm Irgafos 168 and 800ppm zinc stearate). The resulting mixture was physically mixed, twin-screw compounded, and pelletized. The resulting composite resin was then fabricated into films with a thickness of 25 microns using standard blown film processes at a blow-up ratio of 2.5. The resulting film has the following properties:

[0057] Table I. Physical properties of LLDPE blown film

[0058] sample

yield stress

(psi)

breaking stress

(psi)

%Elongation

@break

1% Secant Die

Volume (psi)

Elmendorf

tear (g)

Falling Dart

strike (g)

ASTM

method

D882

D882

...

Embodiment 2

[0062] Example 2: Calcium HHPA in MDPE

[0063] Apply 1000ppm calcium HHPA and standard stabilization pack (500ppm 1010, 1000ppm Irgafos 168 and 800ppm zinc stearate). The resulting mixture was physically mixed, twin-screw compounded, and pelletized. The resulting composite resin was then fabricated into films with a thickness of 25 microns using standard blown film processes at a blow-up ratio of approximately 2.5.

[0064] The resulting film has the following properties:

[0065] Table III. Physical properties of MDPE blown film

[0066] sample

yield stress

(psi)

breaking stress

(psi)

%Elongation

@break

1% Secant Die

Volume (psi)

Elmendorf

tear (g)

Falling Dart

strike (g)

ASTM

method

D882

D882

D882

D882

D1922

D1709

control

2394 / 2466

3580 / 3027

476 / 589

45.2 / 48.3

43 / 331

76

Clarified

...

Embodiment 3

[0071] Calcium HHPA in various types of polyethylene

[0072] Add 1000ppm HHPA calcium to several types of polyethylene (PE) and standard stabilization packs (500ppm 1010, 1000ppm Irgafos 168 and 800ppm zinc stearate). The resulting mixture was physically mixed, single-screw compounded, and pelletized. The resulting composite resin was then fabricated into films with a thickness of 50 microns using standard blown film processes at a blow-up ratio of approximately 2.0. The resulting film has the following optical properties:

[0073] Table V. Optical properties of PE with different comonomer types and catalysts

[0074] resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com