A rotor for DC electromotor

A DC motor and rotor technology, applied in the field of motor manufacturing, can solve the problems of increasing harmful additional dynamic loads, decreasing motor efficiency, and uneven rotation speed, achieving obvious power saving effects, reducing additional resistance loads, and overcoming low torque. zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

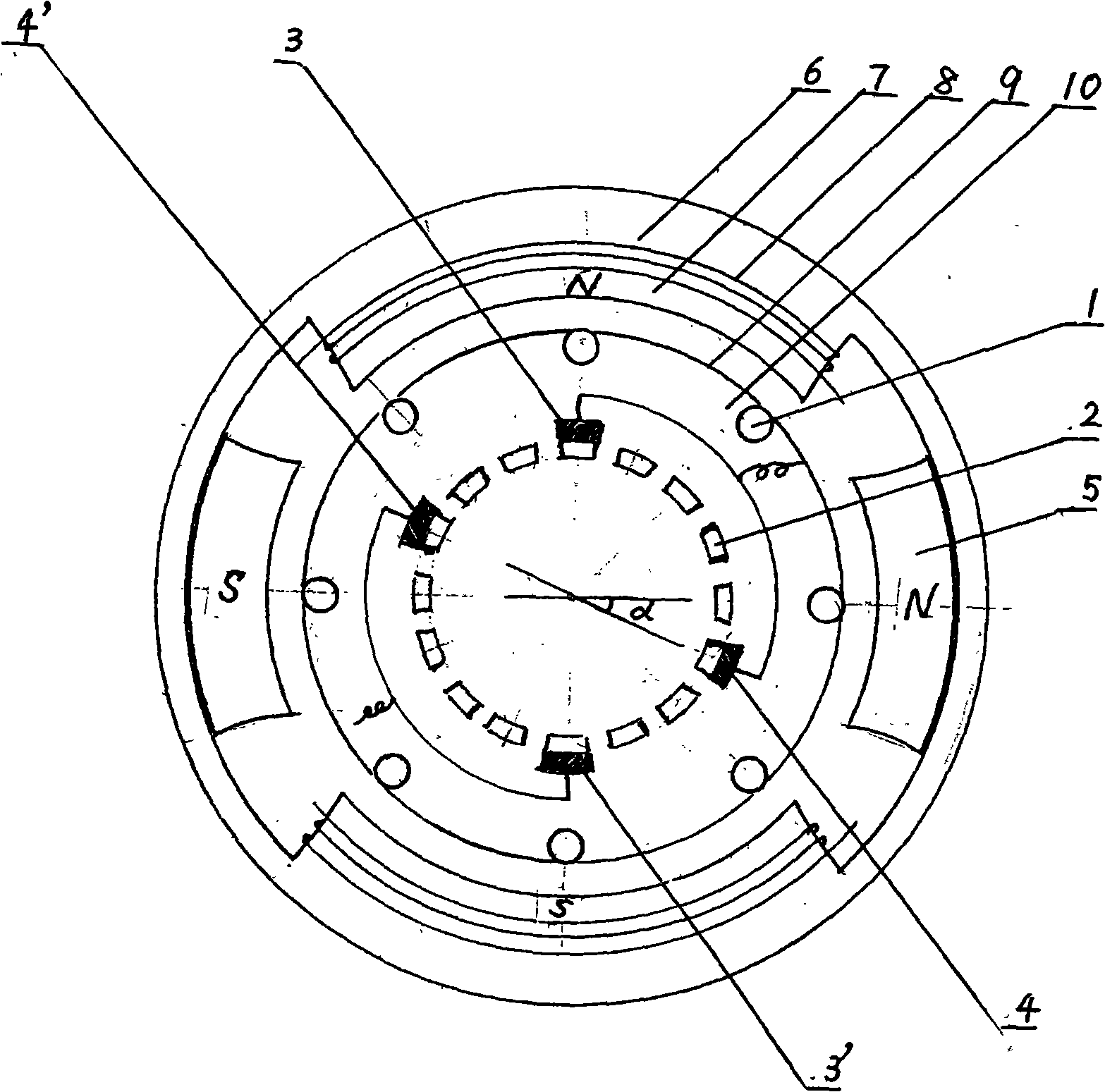

[0008] The present invention is mainly composed of a rotor core 10, a coil 1 with a current commutation piece 2, a pair of commutation carbon brushes 3, 3' placed on the current commutation piece 2, and a pair of passing carbon brushes 4, 4', etc. , one reversing carbon brush 3 is connected with the adjacent passing carbon brush 4, and the other reversing carbon brush 3' is connected with another adjacent passing carbon brush 4'; the straight line of the reversing carbon brush 3, 3' The angle between the straight line passing through the adjacent carbon brushes 4, 4' is 91°-95° in the clockwise direction.

[0009] The rotor 9 of the above-mentioned structure is matched with the stator 6 formed by the stator core 7, the permanent magnet 5 and the winding 8. When used on an electric car, the speed per hour can be changed from the original average to the same under the condition of the vehicle condition, road condition, load and battery capacity. 30KM, the highest 40KM, increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com