Sander for concrete powder

A concrete and grinding machine technology, which is applied in the field of grinding devices, can solve the problems of low grinding efficiency, low grinding accuracy, and inability to produce powder, etc., and achieves high grinding efficiency, convenient operation, and rapid sample preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

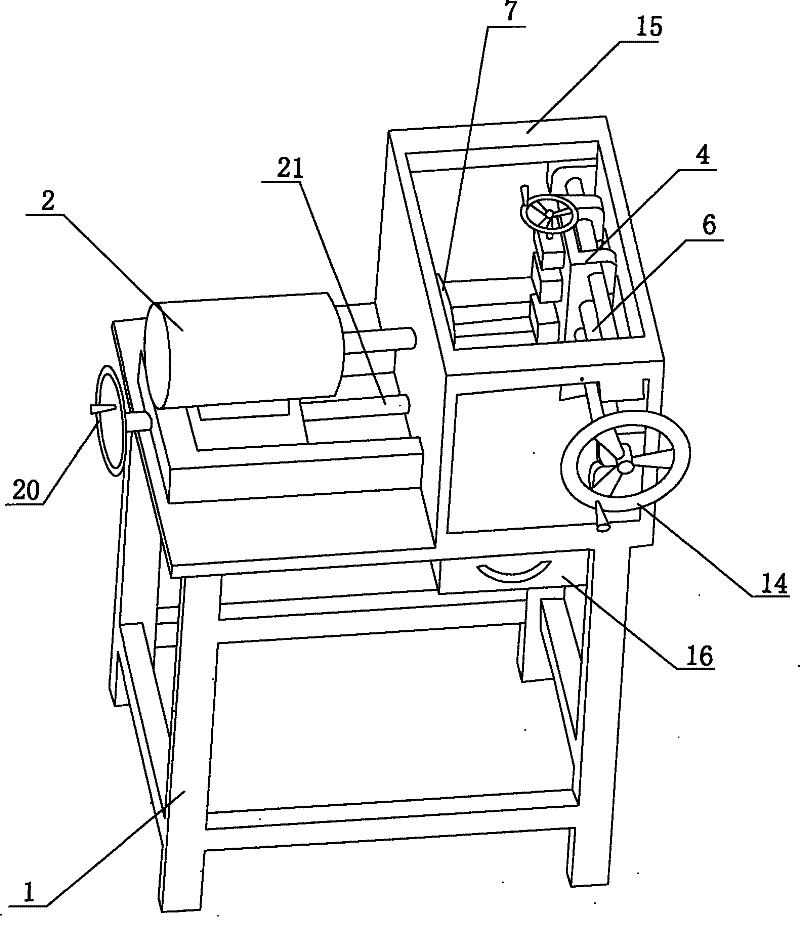

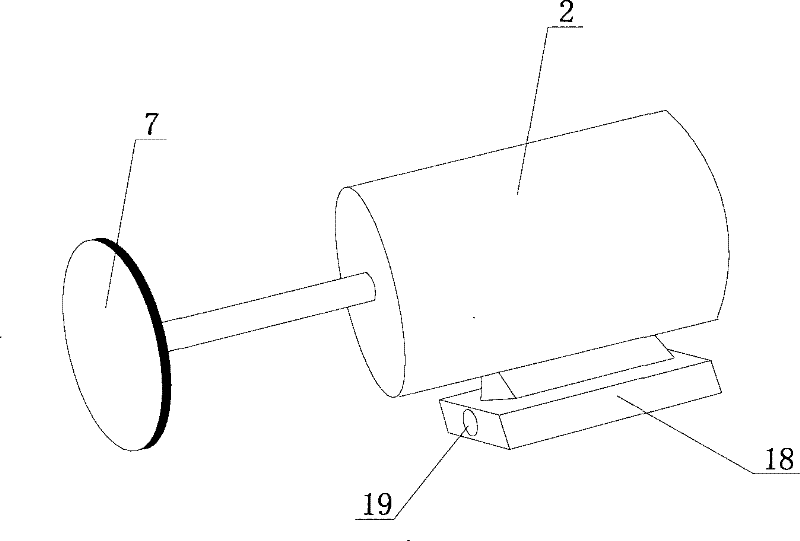

[0015] The grinding device comprises a support 1, on which a motor 2 is arranged, and a grinding sheet 7 is fixedly connected to the rotating shaft of the motor 2, and a test sample holding device 4 is arranged on the opposite side of the grinding sheet 7.

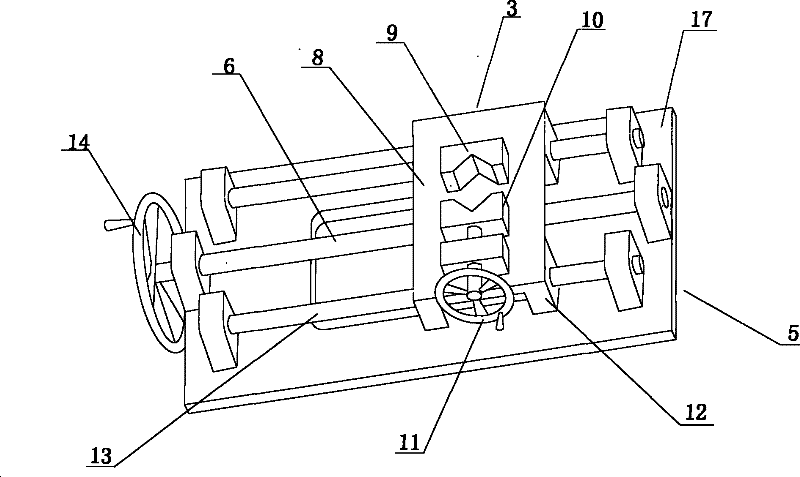

[0016] The clamping device 4 includes a clamping pliers 3 and a transmission mechanism 5 , the clamping pliers 3 are arranged on the transmission mechanism 5 and can slide along the transmission mechanism 5 . Clamping clamp 3 comprises clamping clamp support 8, and one side of clamping clamp support 8 is provided with guide rail frame 12, and the other side of clamping clamp support 8 is provided with fixed clamp 9, and the position relative to fixed clamp 9 is provided with movable clamp 10, The movable clamp 10 is connected with the clamping clamp handle 11, and the clamping clamp handle 11 drives the movable clamp 10 to move, and the distance between the fixed clamp 9 and the movable clamp 10 can be adjusted. Both the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com