Test bench wafer suction disc device

A suction cup, Taiwan crystal technology, applied in the field of test bench wafer suction cup devices, can solve the problems of increasing the test cost, increasing the wafer test time, etc., to reduce the test cost, fix and unload the wafer conveniently, and shorten the test time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

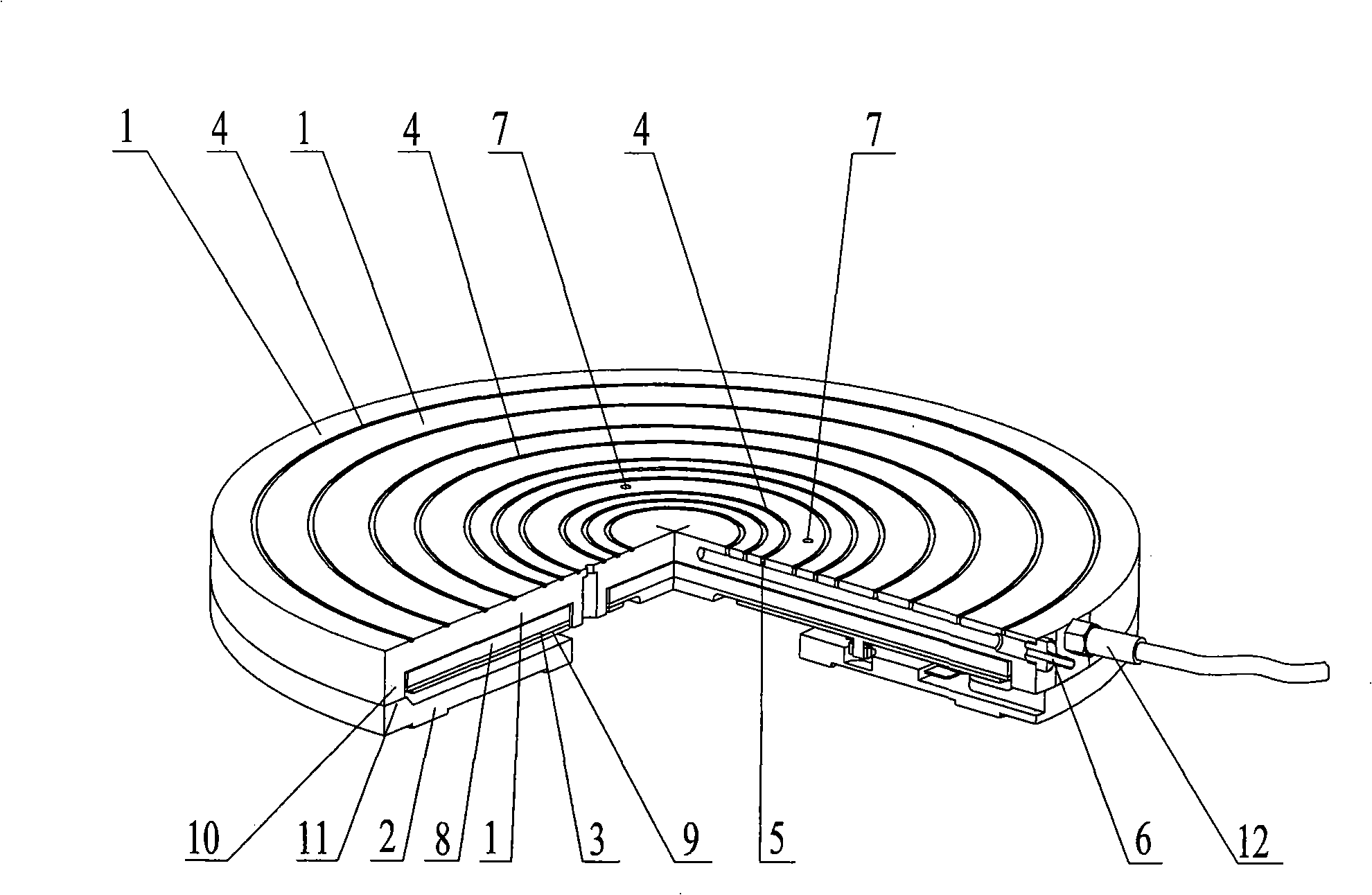

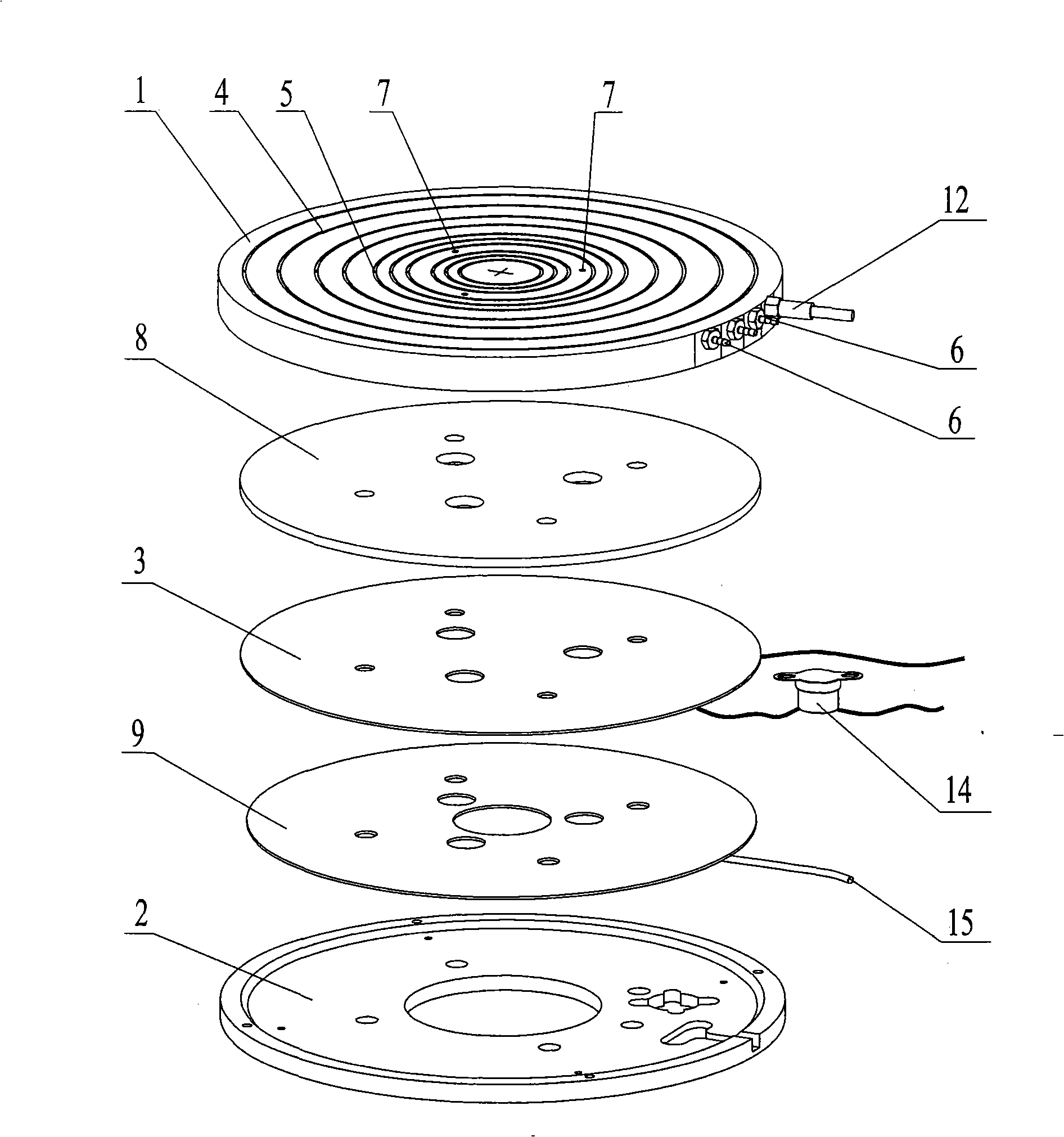

[0010] As shown in the figure: the heater 3 arranged between the negative pressure suction cup 1 and the heat insulation disk 2 is provided with a number of negative pressure air grooves 4 on the upper surface of the negative pressure suction cup 1, and the negative pressure suction cup 1 is provided with a The negative pressure air hole 5 connected to the air groove 4 is provided with a negative pressure air pipe joint 6 on the negative pressure suction cup 1, and the negative pressure air pipe joint 6 communicates with the negative pressure air hole 5. The discharge hole 7 of the suction cup 1, the heater 3 and the insulation tray 2.

[0011] The negative pressure air groove 4 is a concentric circular groove formed on the upper surface of the negative pressure suction cup 1 . There are three or more discharge holes 7, which are evenly arranged between two ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com