Hydrogen engines and its burnt gas jet method

A gas injector and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of low gas charging efficiency and thermal efficiency of hydrogen engines, early combustion and tempering of carburetor engines, insufficient output power, etc. , to achieve the effect of solving the problems of early combustion and tempering, improving combustion and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

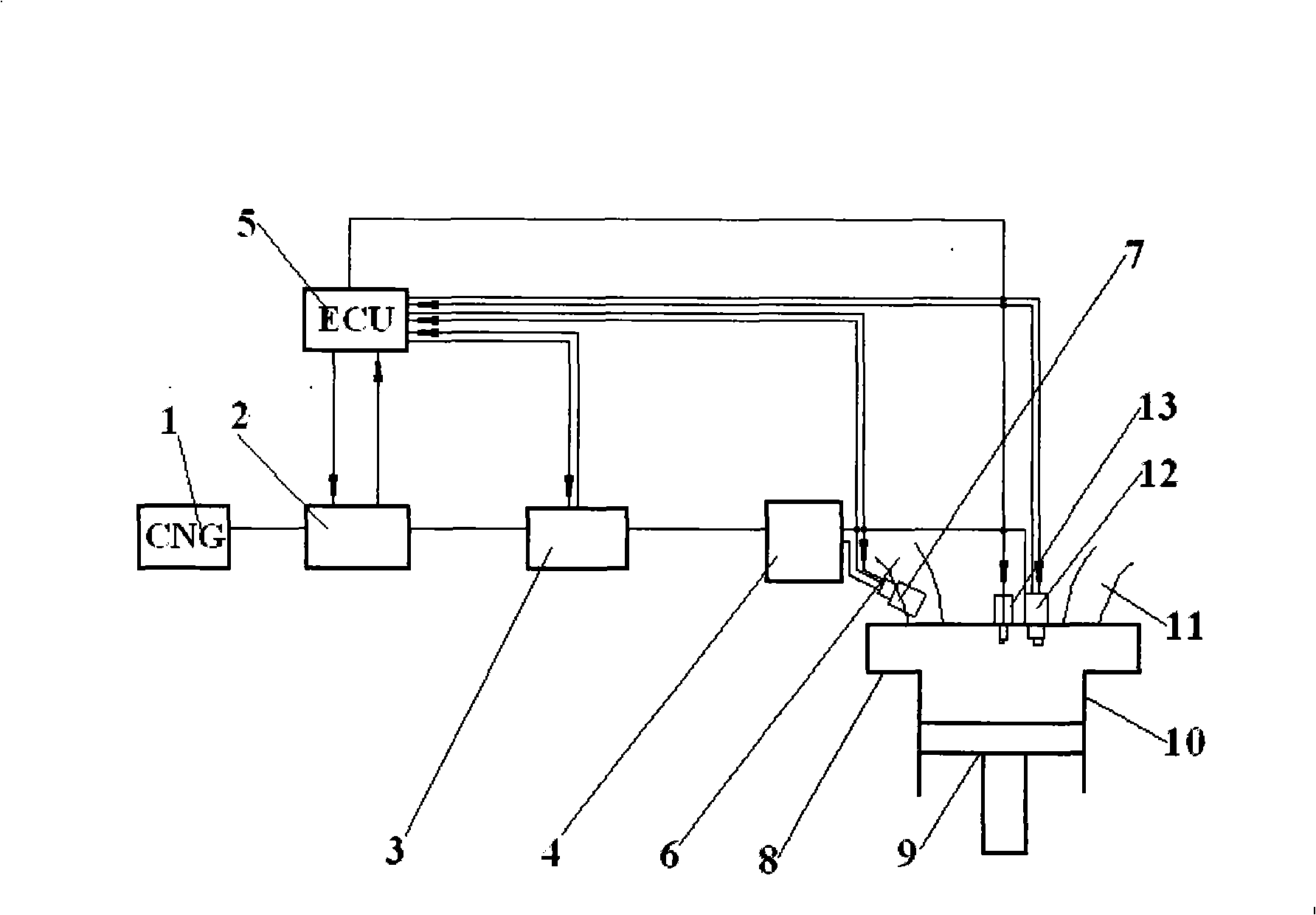

[0029] The gas injector described in the above technique includes an external mixing gas injector 7 for indirect injection and an internal mixing gas injector 12 for direct injection.

[0030] Direct injection and indirect injection are realized by these two different gas injectors. And according to the needs of actual working conditions, control the corresponding gas injectors to perform gas injection under different conditions, or stop the injection. The combination of the two gas injectors realizes the stated purpose of the invention.

Embodiment 2

[0032] The structure and installation method of the external mixed gas injector 7 described in the first embodiment is to communicate with the cylinder 10 through the connection port between the intake manifold 6 and the cylinder head 8 .

[0033] The external mixing gas injector 7 can use the 3.5bar KEIHIN second-generation CNG injector to realize the injection. The external mixing gas injector 7 mixes the hydrogen in the intake port and injects it into the cylinder 10 indirectly.

Embodiment 3

[0035] The structure and installation method of the internal mixed gas injector 12 described in the first embodiment: directly communicates with the cylinder 10 through the cylinder head 8, and is located in the central position of the cylinder head 8 next to the CNG special spark plug 13.

[0036] The internal mixture gas injector 12 injects hydrogen directly into the cylinder. Since the internal mixed gas injector 12 located in the center of the cylinder directly injects near the CNG special spark plug 13 (between the intake valve and the exhaust valve), the charging efficiency is improved and the power of the engine is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com