Concrete and induration formed composite type pile and its manufacture method

A manufacturing method and a composite technology, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing replacement rate, increasing the number of piles, and increasing the diameter of the pile, achieving high economy, improving Pile side friction resistance and the effect of improving pile end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

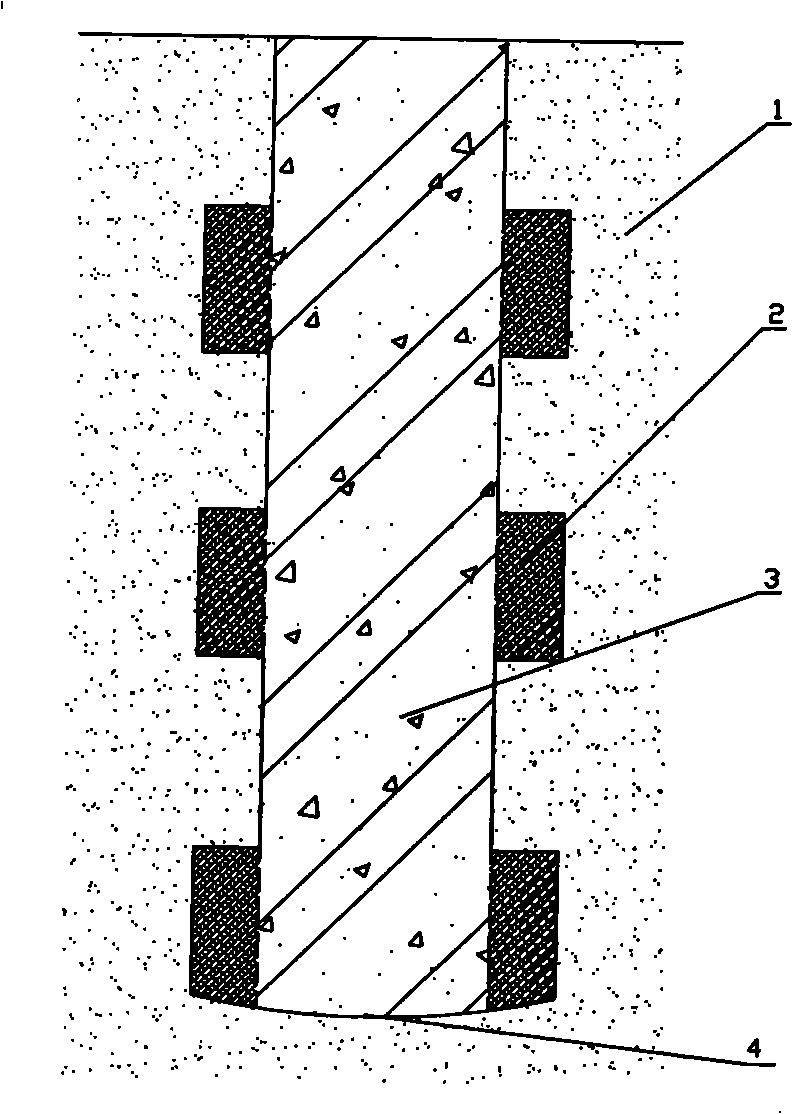

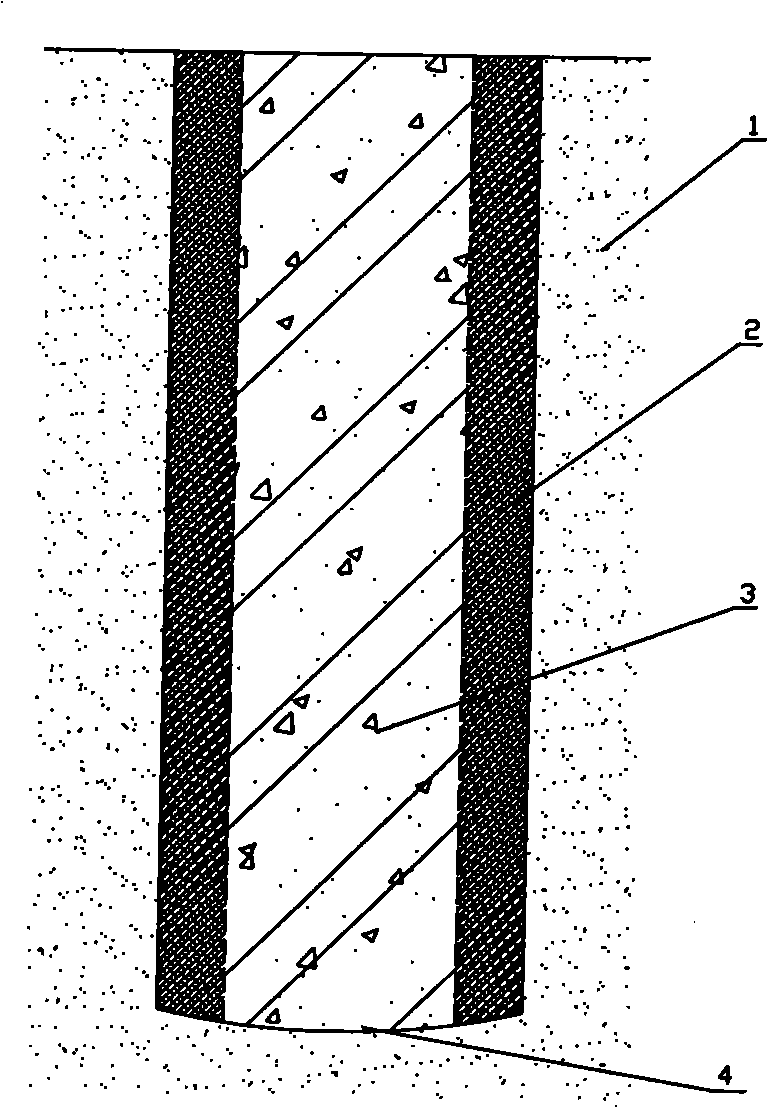

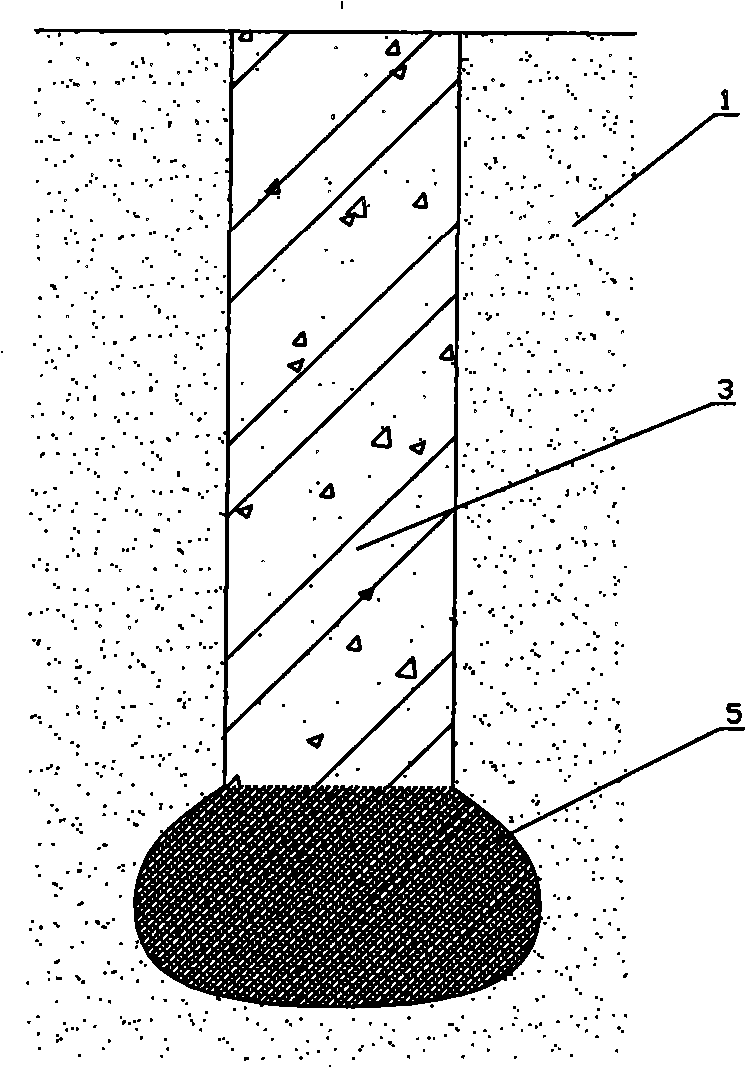

[0025] Such as figure 1 — Figure 5 Shown in, the composite pile body (CCG pile body) of multiple combinations provided by the present invention mainly consists of reinforced concrete or plain concrete pile body 3 and pile side consolidation bodies 2 of different shapes formed by pile side spray grouting and The pile bottom consolidation body 5 formed after the pile bottom spraying is completed by different combinations. In the figure 1 is the surrounding undisturbed soil, 2 is the pile side consolidation body of different shapes formed by the pile side spraying grouting, and 3 is reinforced concrete or Plain concrete pile body, 4 is the pile end without grouting at the bottom of the pile, and 5 is the consolidated body at the bottom of the pile formed after grouting at the bottom of the pile. figure 1 The composite pile body is composed of reinforced concrete or plain concrete pile body 3 and pile side consolidation body 2 distributed in sections, and the pile end 4 is not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com