Post-grouting cast-in-place thin-wall pipe pile with grouting pipeline being reserved and construction method

A technology of thin-walled pipe piles and grouting pipes, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of weakening pile end resistance, weakening pile side resistance, and affecting bearing capacity, so as to improve pile end resistance , improve the carrying capacity, and facilitate popularization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

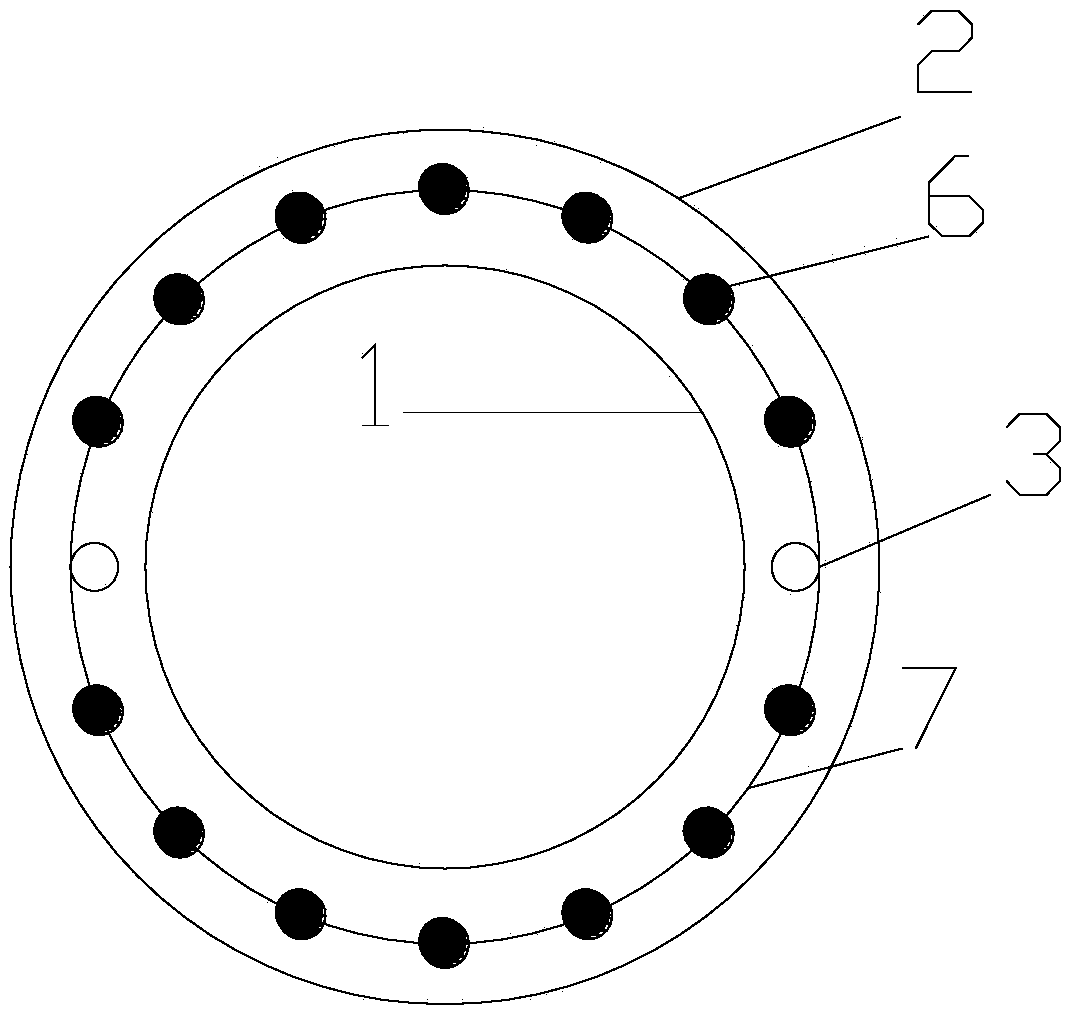

[0032] Such as Figure 1 to Figure 4 As shown, the post-grouting cast-in-place thin-walled pipe pile of the reserved grouting pipeline improves the performance of the cast-in-place thin-walled pipe pile, so that it has the post-grouting function of the pile end and pile side, and increases responses such as necking, The ability to solve engineering problems such as broken piles and insufficient bearing capacity. The post-grouting cast-in-place thin-walled pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com