Numerically-controlled cam grinder

A technology of cam grinder and bed, which is applied in the field of CNC cam grinder, can solve the problems of product qualification rate drop, low efficiency, complex manufacturing, etc., and achieve the effect of reducing the intermediate process of machine operation, improving production efficiency, and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

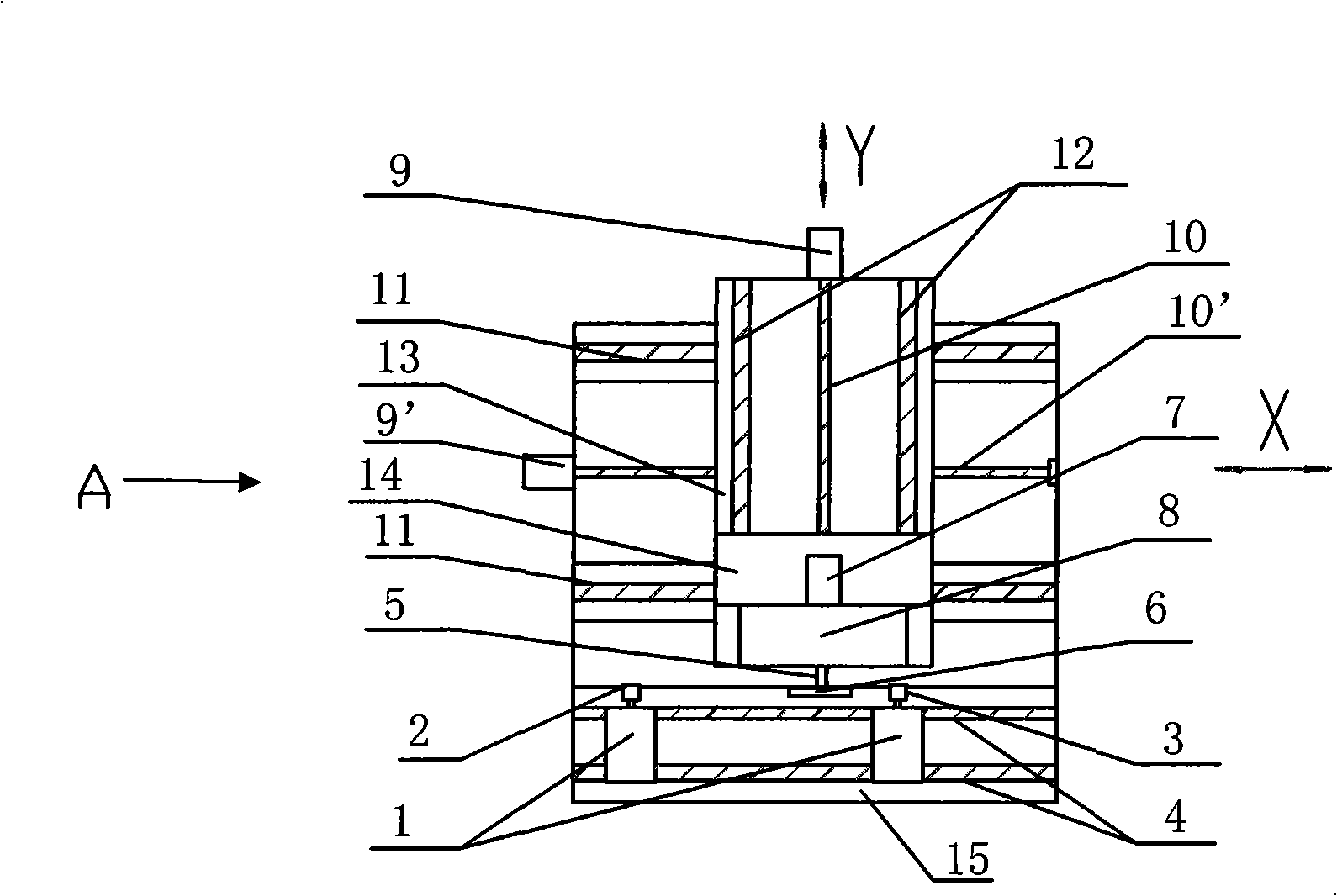

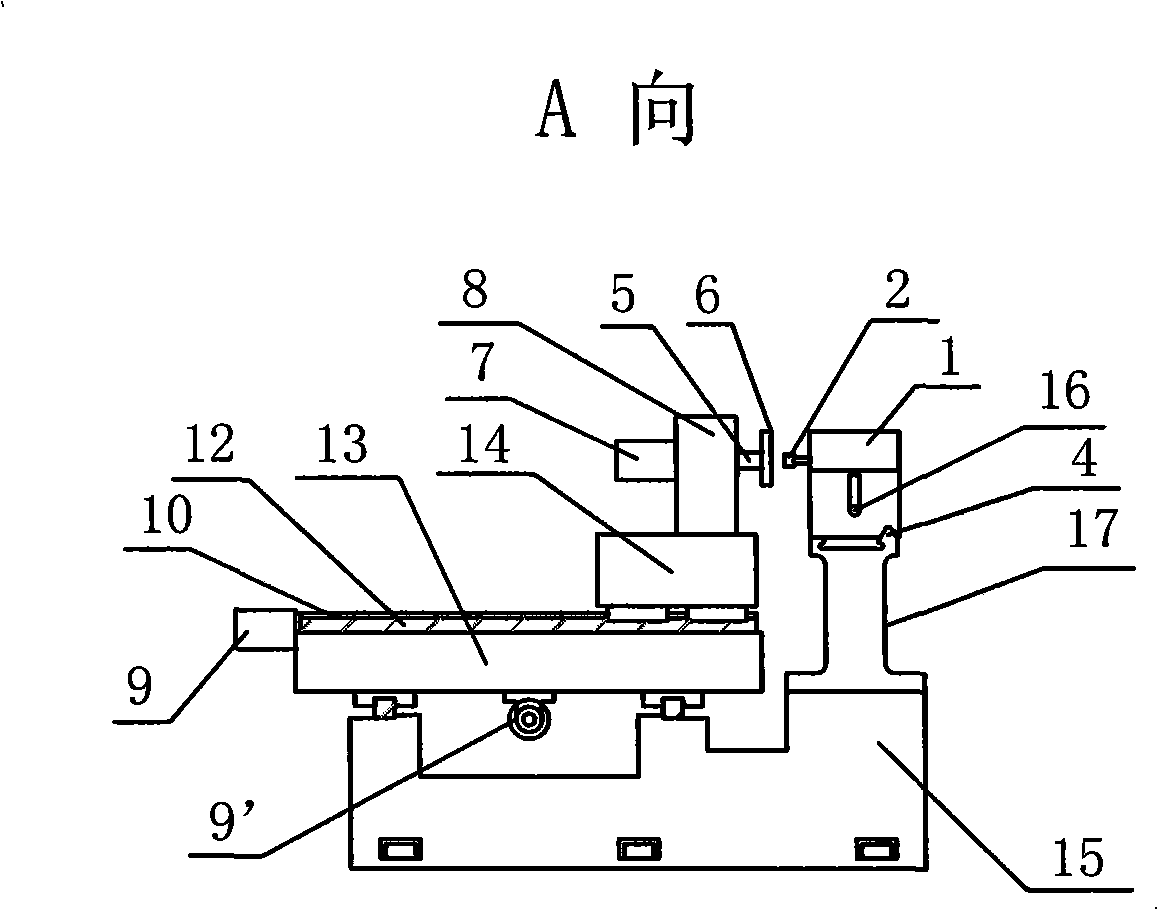

[0012] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , 2 As shown, a numerically controlled cam grinding machine includes a numerically controlled table, a bed 15, a workbench 14, a grinding wheel frame 1, etc., and a fine grinding head 2 and a rough grinding head are respectively installed on the transverse track 11 of the grinding wheel frame 17 on one side of the machine tool 3, two grinding wheel holders 1, the grinding wheel holder 1 is fixed on the grinding wheel holder seat 17 through positioning pins, and the position of the grinding wheel holder can be adjusted on the track as required, the grinding wheel holder seat is fixed on the machine tool, and the workbench is opposite to the grinding wheel holder seat Standing, and a horizontal sliding table is arranged under the workbench, on which there is a longitudinal guide rail matched with the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com