Coal-burning and coal-saving additive agent mixing/stirring conveyor

A coal-saving additive, mixing and stirring technology, which is used in mixers, mixers with rotary mixing devices, and dissolution, etc. problems, to achieve the effect of good coal saving, energy saving and emission reduction, and improving coal saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

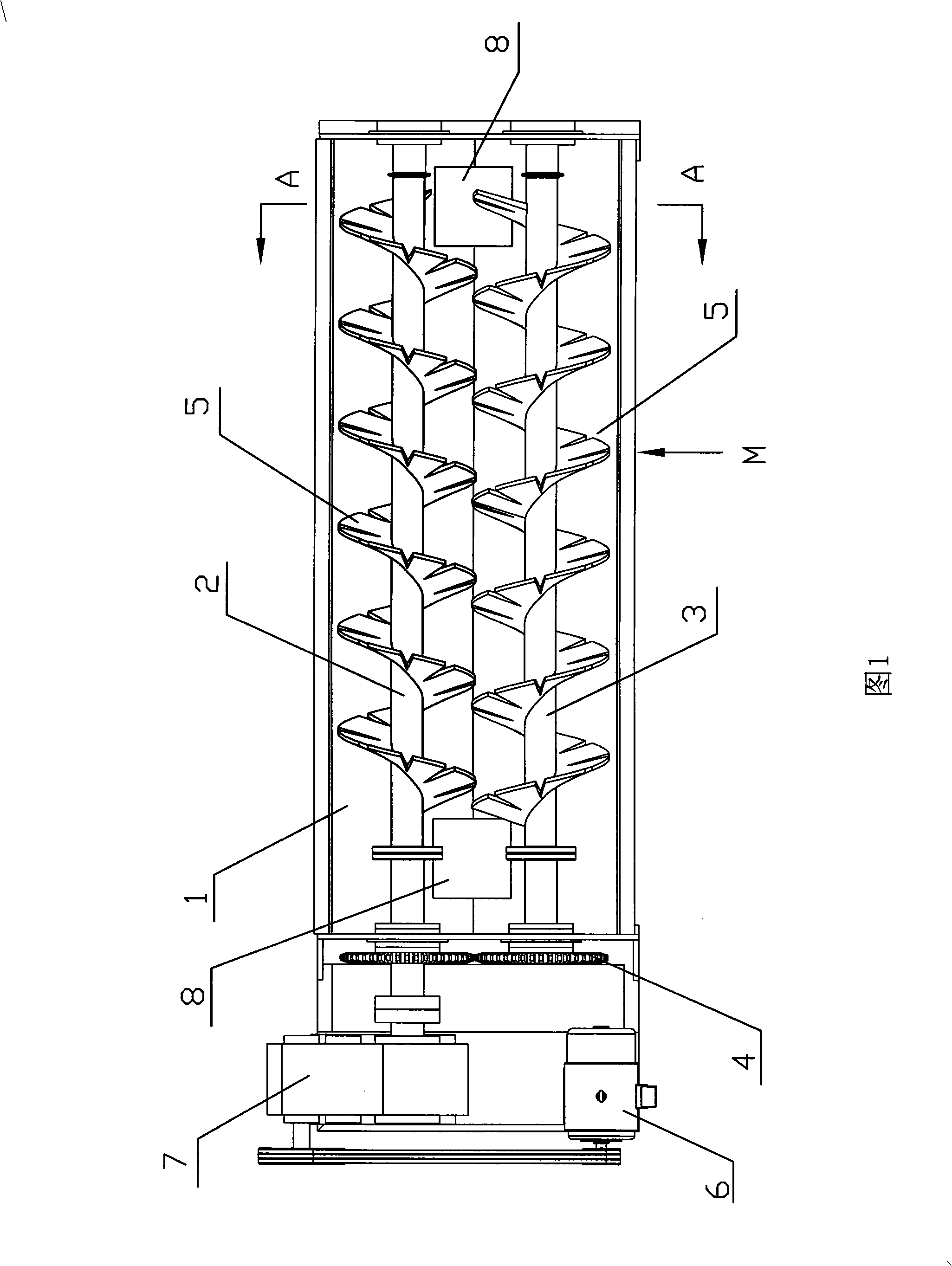

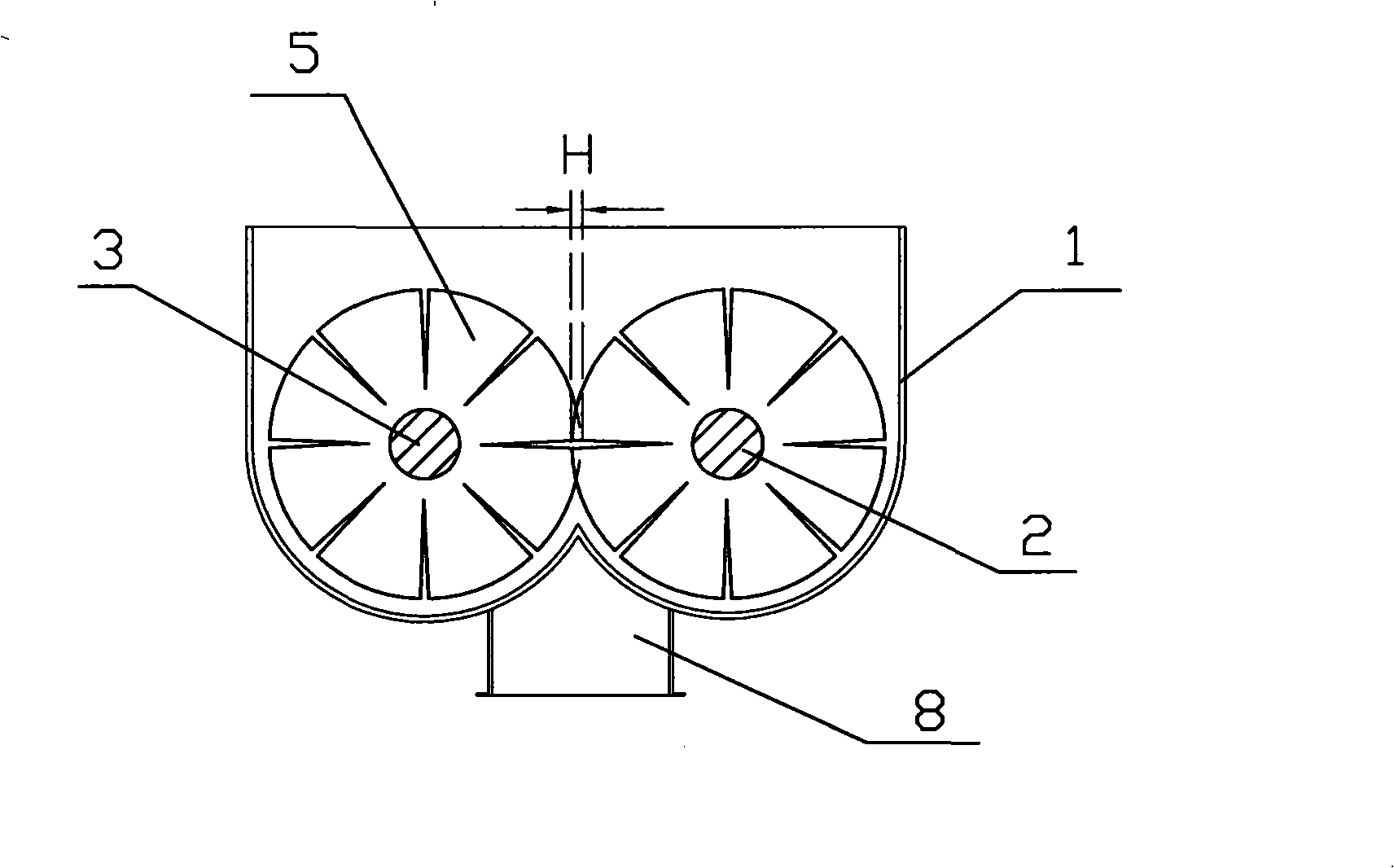

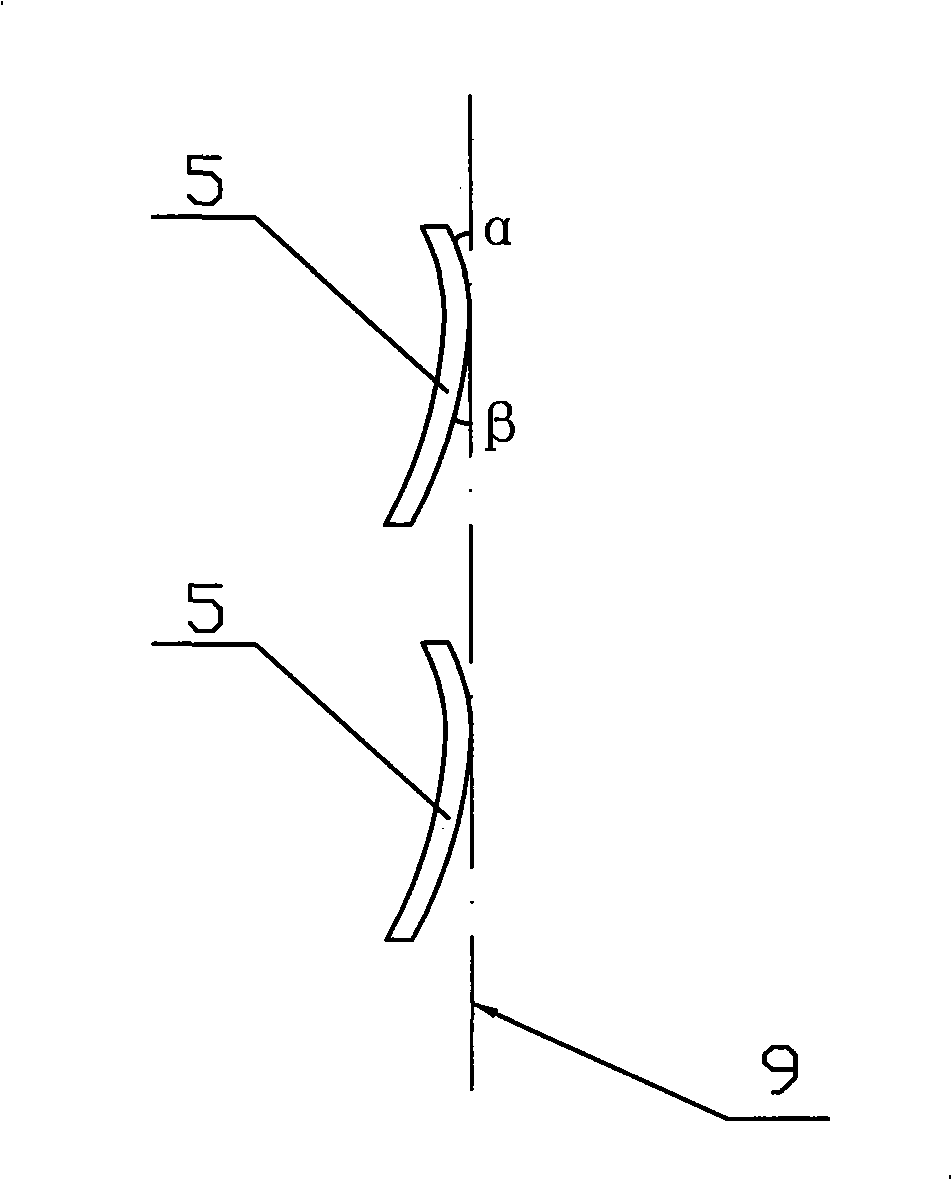

[0023] Embodiment 1: The coal-burning and coal-saving additive mixing and stirring conveyor of this embodiment, as shown in Figure 1, the shell is a tank body 1 arranged horizontally, the cross section of the tank body 1 is "W", and its bottom is double Arc-shaped, the main shaft 2 and the spoke shaft 3 parallel to each other are installed in the tank body 1 along the length direction of the tank body, and the ends of the two shafts are connected with a gear 4, and the two gears are meshed, and there are many blades 5 arranged in a helical line On the main shaft 2 and the spoke shaft 3, the spiraling directions of the two helices are opposite, and the outer edges of the blades on the main shaft 2 and the blades on the spoke shaft 3 have overlapping parts H in the axial direction, such as figure 2 As shown, eight blades 5 are distributed on every 360° helix 9 , the roots of all the blades 5 are connected and the tops are separated, and the roots of the blades form a continuous h...

Embodiment 2

[0026] Embodiment 2: the coal-burning and coal-saving additive mixing and stirring conveyor of this embodiment, as shown in Figure 4, Figure 5 As shown, the root and the top between the blade 5 and the blade are all separated, and there is a certain distance between the roots. The root of the blade forms a discontinuous helix 9 on the main shaft 2 and the spoke shaft 3 respectively, and every 360° of the helix Five blades 5 are distributed on the line 9 . Such as Figure 6 As shown, the leaf surface of each blade 5 is an "S"-shaped curved surface composed of two curved surfaces smoothly connected, and the angle γ formed between the tangent line of the outer edge of the curved surface and the helix 9 is 26°.

[0027] When this embodiment is in use, the tank body can be arranged horizontally. This embodiment is applicable to the original coal-fired conveyor belt, which is a large-scale coal-consuming unit set horizontally, to ensure that the original conveying direction and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com