Hollow fiber compound film, preparation and application

A fiber composite and hollow technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high energy consumption, long process flow, complicated refining system, etc., and achieve simple preparation process and rich raw material sources. , the effect of high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

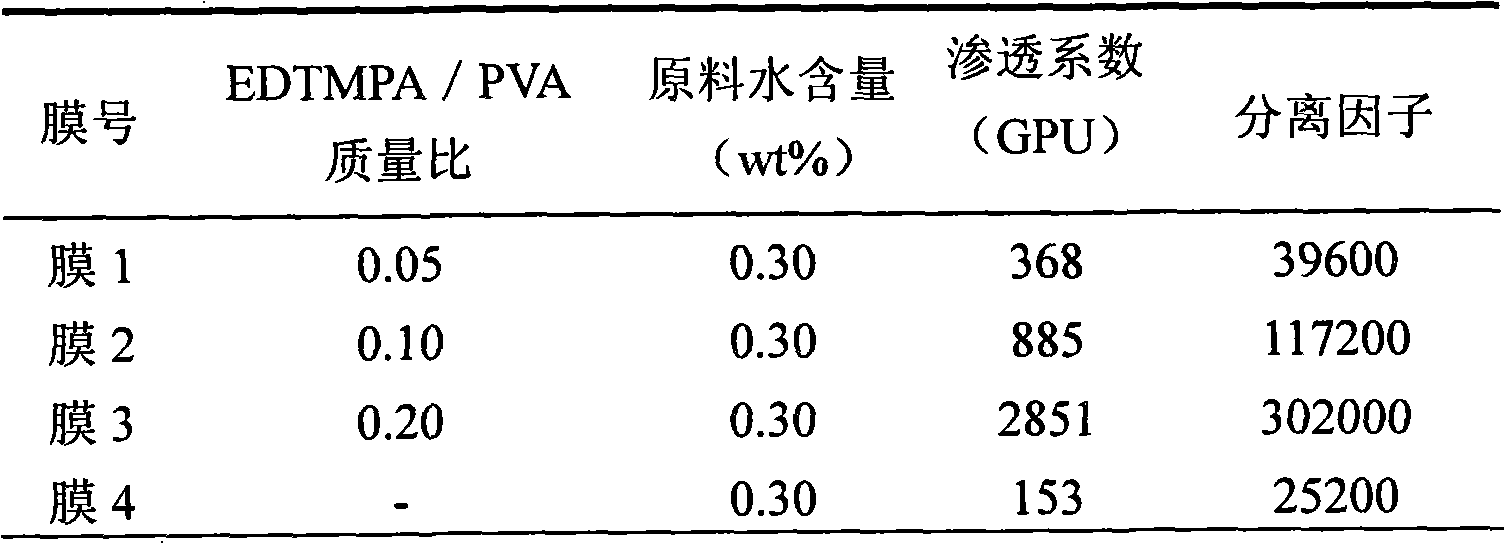

Embodiment 1

[0015] The preparation of embodiment 1 PVA-EDTMPA / PS hollow fiber composite membrane (membrane 1)

[0016] Weigh 5.0g of polyvinyl alcohol with a degree of polymerization of 1750±50 and 95g of deionized water into a three-necked flask, heat in a constant temperature water bath at 90°C, and dissolve for 1.5h while stirring at 900r / min. After completely dissolving, it is lowered to 25° C. to prepare an aqueous solution of polyvinyl alcohol with a mass concentration of 5%. Add 0.25 g of EDTMPA to the polyvinyl alcohol aqueous solution under the condition of stirring at 900 r / min, stir for 2 hours and mix evenly, filter the membrane-forming liquid through a screen to remove impurities, and then let stand for defoaming. Then the polysulfone (PS) hollow fiber support layer was soaked in the foam-free casting solution for 10 minutes, and dried at 20-25° C. for 12 hours to obtain a PVA-EDTMPA / PS hollow fiber composite membrane (membrane 1).

[0017] The prepared film 1 is subjected t...

Embodiment 2

[0018] The preparation of embodiment 2 PVA-EDTMPA / PS hollow fiber composite membrane (membrane 2)

[0019] Weigh 5.0g of polyvinyl alcohol with a degree of polymerization of 1750±50 and 95g of deionized water into a three-necked flask, heat in a constant temperature water bath at 90°C, and dissolve for 1.5h while stirring at 900r / min. After completely dissolving, it is lowered to 25° C. to prepare an aqueous solution of polyvinyl alcohol with a mass concentration of 5%. Add 0.5 g of EDTMPA to the aqueous solution of polyvinyl alcohol under stirring at 900 r / min, stir for 2 hours and mix evenly, filter the membrane-forming solution through a sieve to remove impurities, and then let stand for defoaming. Then the polysulfone (PS) hollow fiber support layer was soaked in the foam-free casting solution for 10 minutes, and dried at 20-25° C. for 12 hours to obtain a PVA-EDTMPA / PS hollow fiber composite membrane (membrane 2).

[0020] The prepared film 1 is subjected to scanning ele...

Embodiment 3

[0021] The preparation of embodiment 3 PVA-EDTMPA / PS hollow fiber composite membrane (membrane 3)

[0022] Weigh 5.0g of polyvinyl alcohol with a degree of polymerization of 1750±50 and 95g of deionized water into a three-necked flask, heat in a constant temperature water bath at 90°C, and dissolve for 1.5h while stirring at 900r / min. After completely dissolving, it is lowered to 25° C. to prepare an aqueous solution of polyvinyl alcohol with a mass concentration of 5%. Add 1.0 g of EDTMPA to the polyvinyl alcohol aqueous solution under stirring at 900 r / min, stir for 2 hours and mix evenly, filter the membrane-forming solution through a screen to remove impurities, and then let stand for defoaming. Then the polysulfone (PS) hollow fiber support layer was soaked in the foam-free casting solution for 10 minutes, and dried at 20-25° C. for 12 hours to obtain a PVA-EDTMPA / PS hollow fiber composite membrane (membrane 1).

[0023] The prepared film 1 is subjected to scanning elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com