Extended refrigerated shelf life mashed potatoes

A technology for mashed potatoes and shelf life, applied in the fields of fruit and vegetable preservation, food science, food preservation, etc., can solve the problems of limited and poor taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

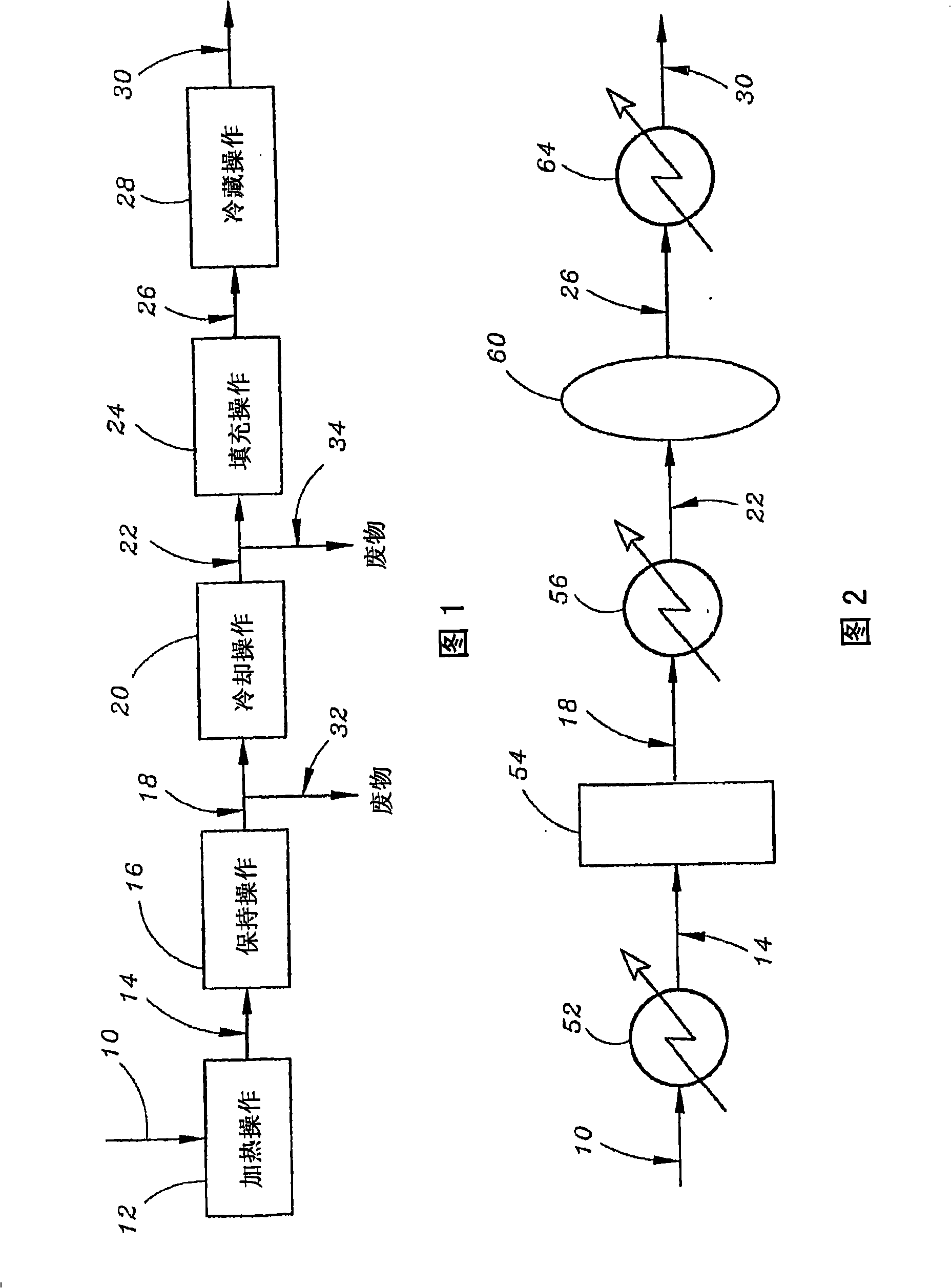

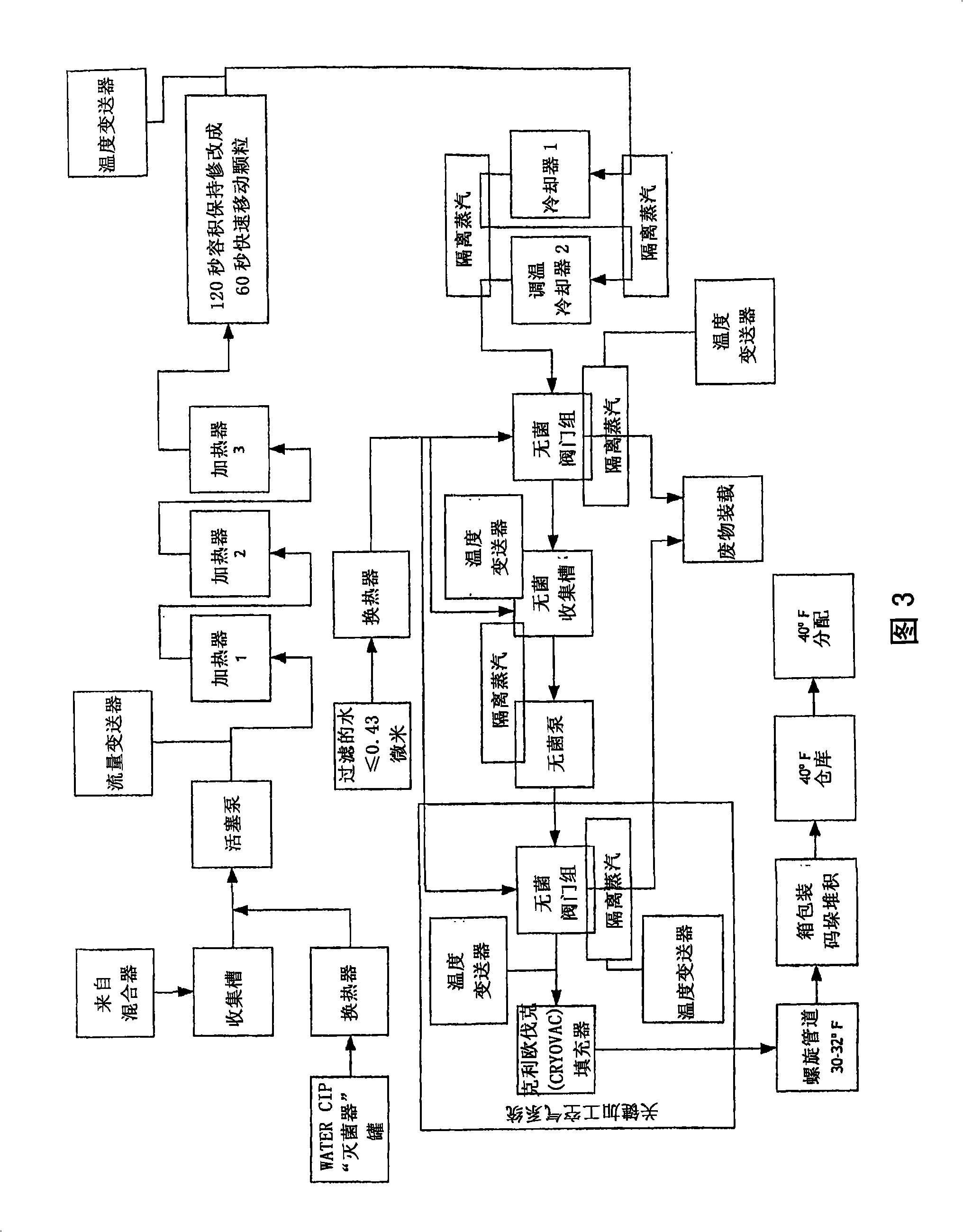

Method used

Image

Examples

Embodiment 1

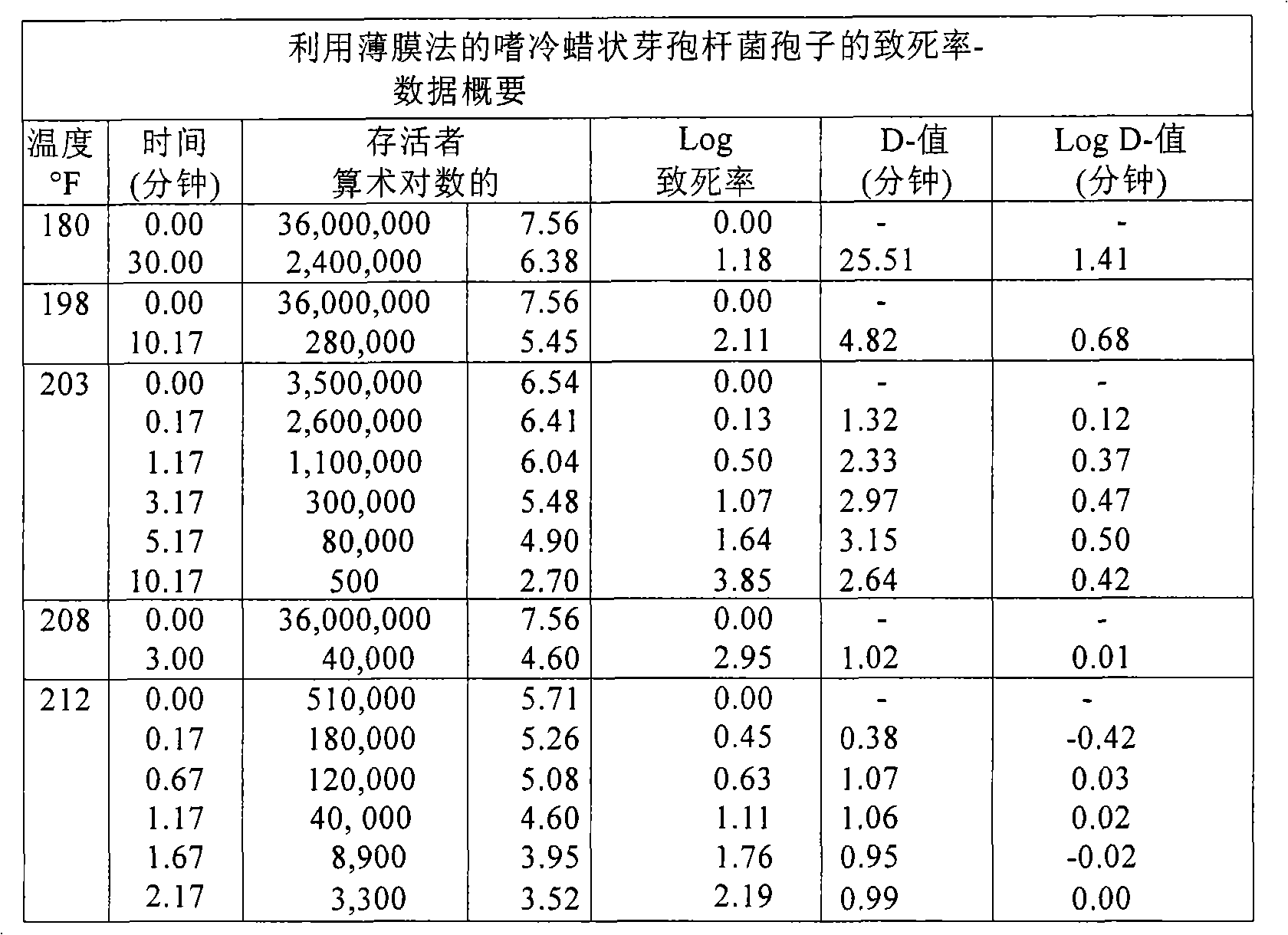

[0041] This example investigates the destruction of psychrophilic Bacillus cereus spores by varying the time and temperature at which mashed potato samples are heated.

[0042] For this work, four strains obtained from Dr. Larry Beuchat (University of Georgia) were used. Spores of four psychrophilic Bacillus cereus strains were prepared by spreading overnight cultures on Petri dishes on nutrient agar containing manganese sulfate (NAMS), incubated at 30°C for 4 days and analyzed using a sterile glass microscope. Slide collection. Multiple washes, vortexing, and ultrasonic baths were used to obtain a clean spore suspension with minimal clotting, and this was confirmed by microscopy.

[0043]Approximately equal numbers of the respective spore harvests were thoroughly mixed with mashed potatoes. Studies with inoculated mashed potatoes were conducted using 50 g of potatoes in an ultra-thin "read-through" layer measuring 6-3 / 4 inches by 9 inches in heat-sealed pouches made from Wh...

Embodiment 2

[0046] This example investigates the destruction of psychrophilic Bacillus cereus spores when a sample of mashed potatoes is heated to a temperature of approximately 212°F for one minute.

[0047] Four psychrophilic Bacillus cereus strains were reisolated from those used in Example 1 by streaking onto MYP agar and incubating at 86°F for 48h. Isolated colonies of the respective strains were transferred to brain heart infusion broth and incubated overnight at 86°F. 0.1 ml of the culture from each tube was plated onto nutrient agar (NAMS) supplemented with manganese sulfate to induce sporulation. After 4 days of incubation at 86°F, spores were removed, washed with 0.85% saline solution, centrifuged to remove vegetative cells, and vortexed with sterile glass beads to break up any spore clumps. The suspension was examined by phase contrast microscopy to ensure that there were no significant numbers of vegetative cells and no significant spore masses.

[0048] Combine equal volume...

Embodiment 3

[0054] This example determines the aerobic plate count (APC), mold count, and yeast count of a mash potato product inoculated with the same strain used in Example 1 heated to 213°F for 1 minute and then stored at 40°F for 147 days. The experiment was terminated after 147 days. Sample 1 and Sample 2 are duplicate samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com