Straightthrough type double glazing vacuum solar heat collection tube

A solar heat collection tube and double-layer glass technology, applied in the field of solar energy applications, can solve the problem of low heat collection efficiency, achieve good heat collection effect, avoid tube explosion, and reduce the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

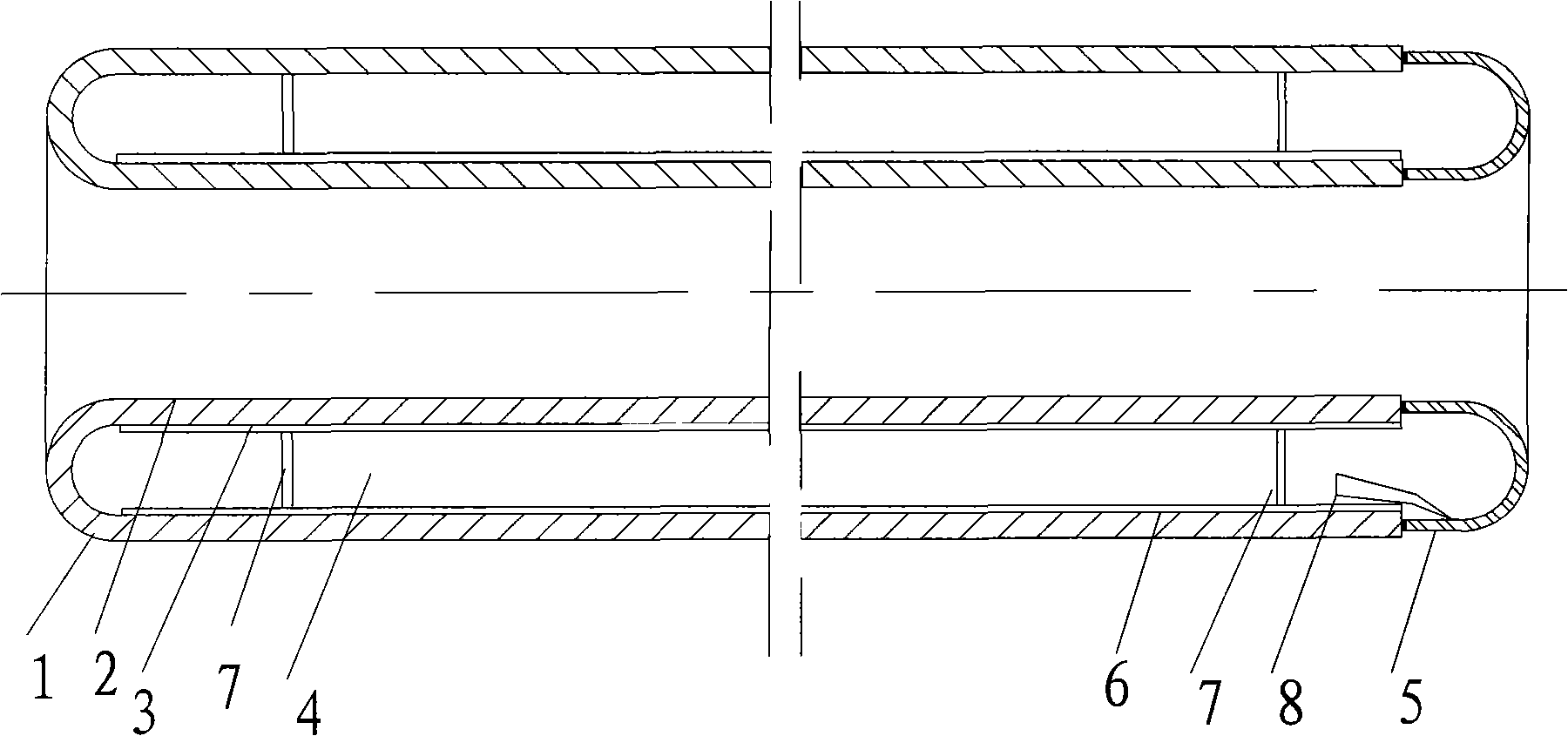

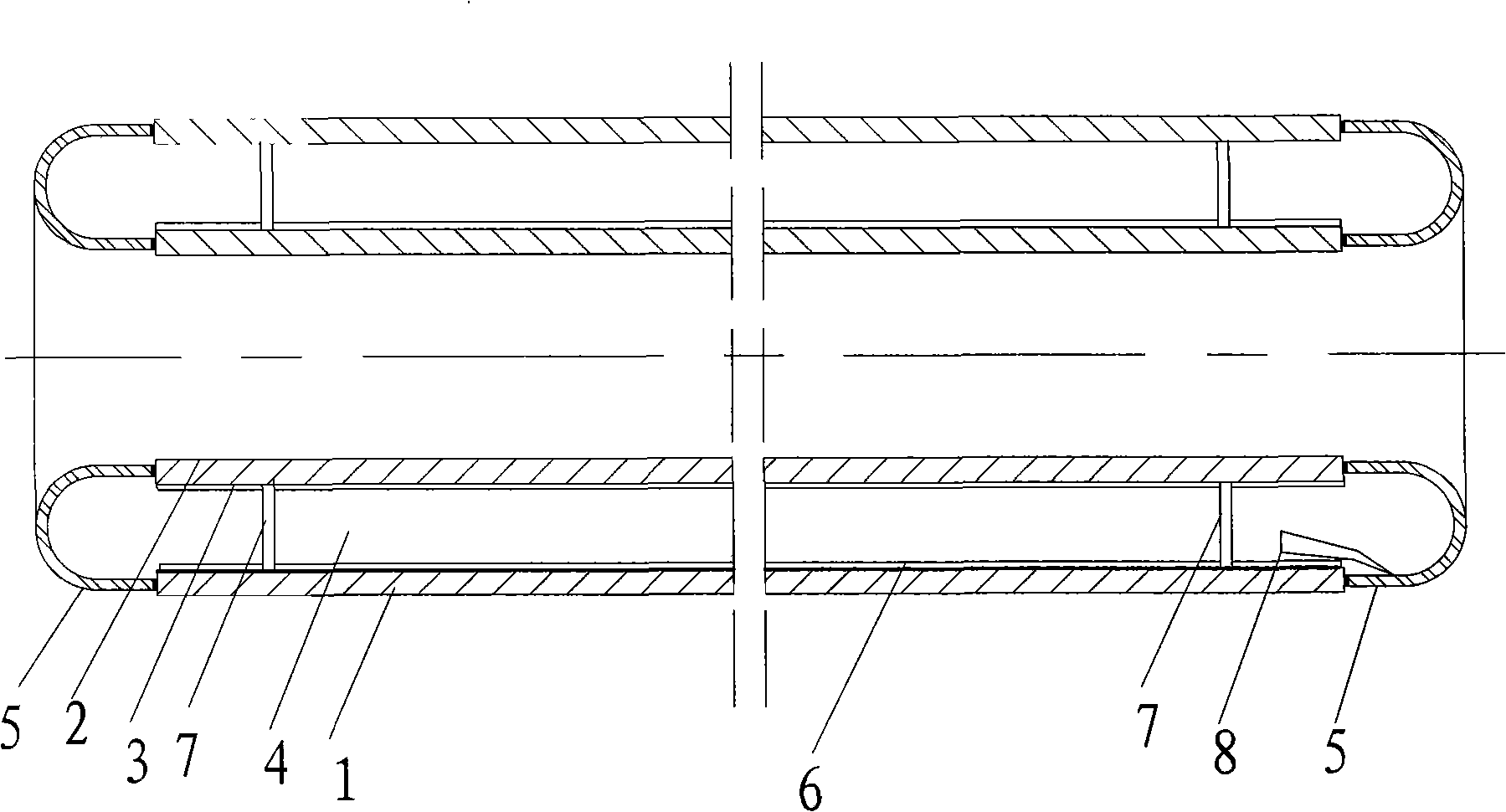

[0027] Such as figure 1 The straight-through double-glazed vacuum solar collector tube shown includes a glass outer tube 1 and a glass inner tube 2 arranged in the glass outer tube. The glass inner tube is open at both ends, and the outer surface of the glass inner tube is provided with solar energy selection The absorbent coating 3 has a vacuum space 4 between the glass inner tube and the glass outer tube, and a getter 8 can be placed in the vacuum space to ensure a better vacuum effect. A light-concentrating and reflecting element 6 is provided between the backlight surface of the glass inner tube and the glass outer tube, and an expansion joint 5 is arranged at one end of the straight-through double-glazed vacuum solar collector tube. The expansion joint 5 is shown in Fig. 5 , Figure 6 The section shown is a U-shaped annular expansion joint, which is made of elastic material, and the linear expansion coefficient of this material is 3×10 -6 m / m·℃ to 5×10 -6 between m / m·℃. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com