Transmission mechanism of integral power shift hydraulic transmission for engineering machinery

A hydraulic transmission and power shifting technology, which is applied in the field of components of the integral power shifting hydraulic transmission, can solve the problems of complex transmission chain form and low transmission efficiency, and achieve fast backward easy, high transmission efficiency, and rapid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

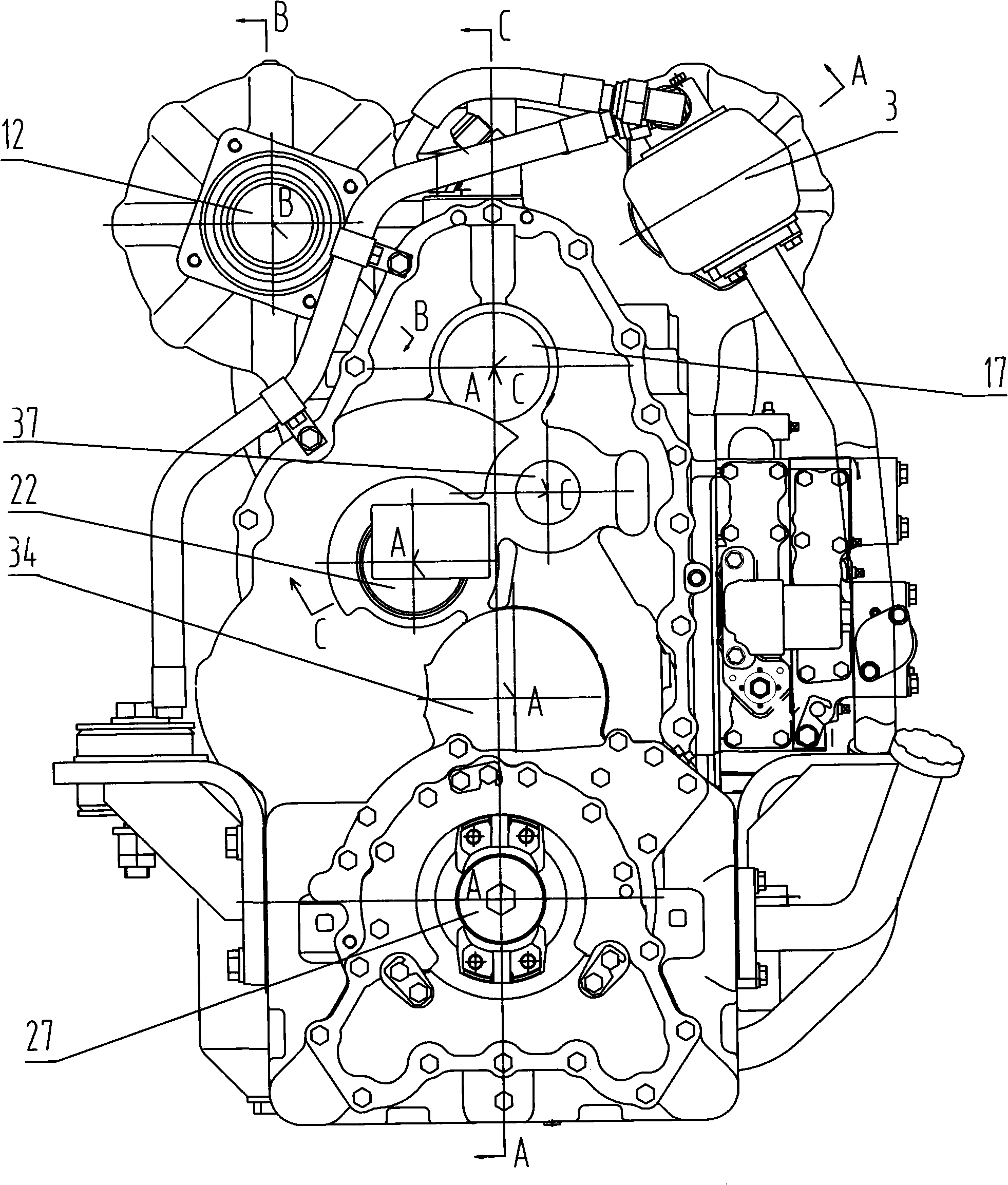

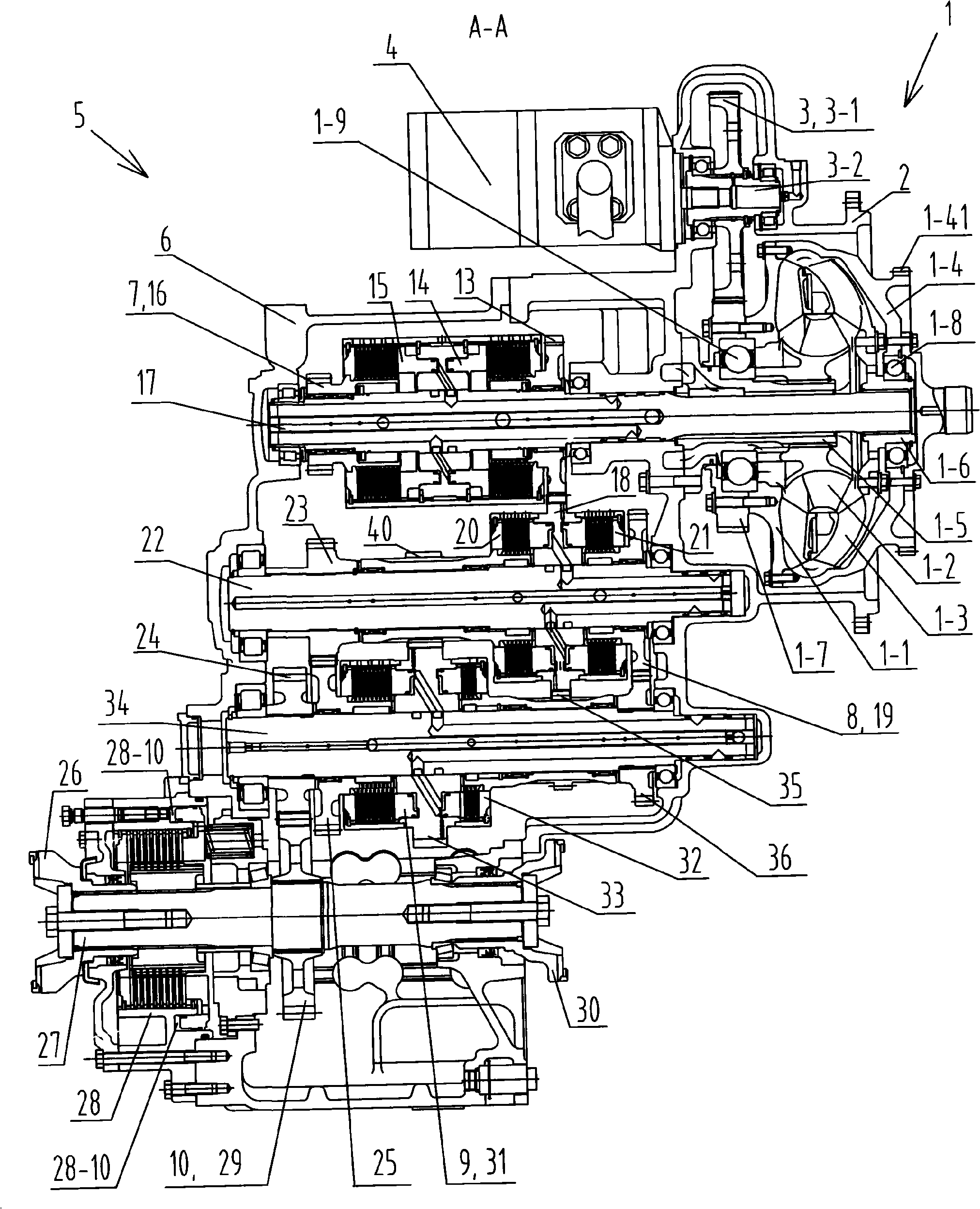

[0035] See figure 1 and figure 2 , The transmission mechanism of the integrated power shift hydraulic transmission of the present embodiment has a left box body 6, a right box body 2, a hydraulic torque converter 1 and a power shift fixed shaft transmission device 5. The left box body 6 is fixedly connected with the right box body 2 to form a box body.

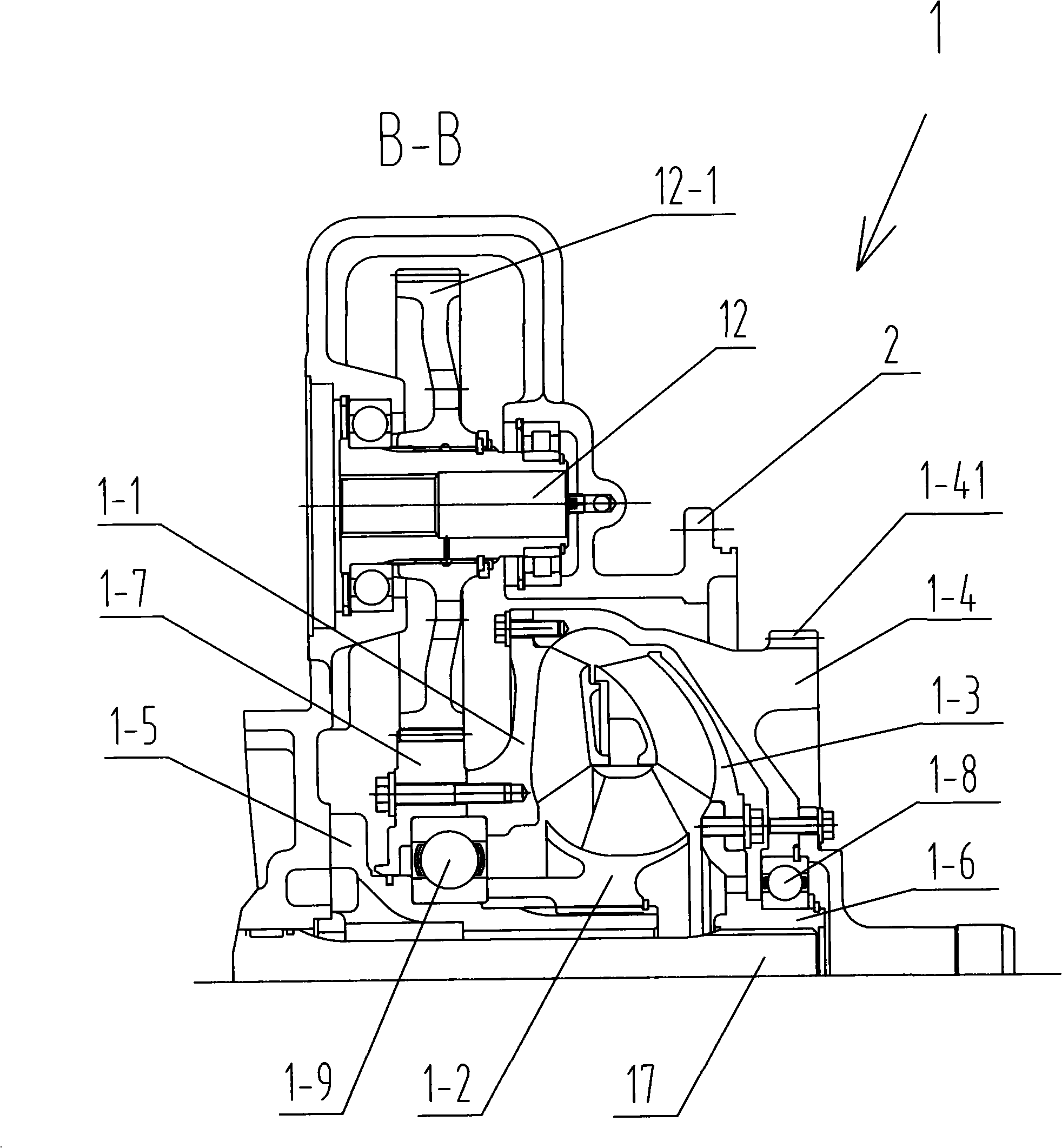

[0036] See figure 2 and image 3 , the hydraulic pitch changer 1 is a single-stage single-phase centripetal hydraulic pitch changer, which has a pump wheel 1-1, a guide wheel 1-2, a turbine 1-3, a pump casing 1-4, and a guide wheel seat 1- 5. Turbine seat 1-6, pump wheel gear 1-7, pump casing gear 1-41, first power take-off device 3, second power take-off device 12 and power output shaft 17. The power output shaft 17 is the same shaft as the input shaft 17 of the transmission 5 .

[0037] See figure 2 , image 3 and Figure 5 , the left end of the input shaft 17 is supported on the left case body 6 through a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com