Feed liquid backswing agitating device

A stirring device and material-liquid technology, which is applied in mixers with rotary stirring devices, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of short circuit of liquid flow, strong impact force of materials, leakage failure, etc. Achieve the effect of simple device structure, less power consumption and less operation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

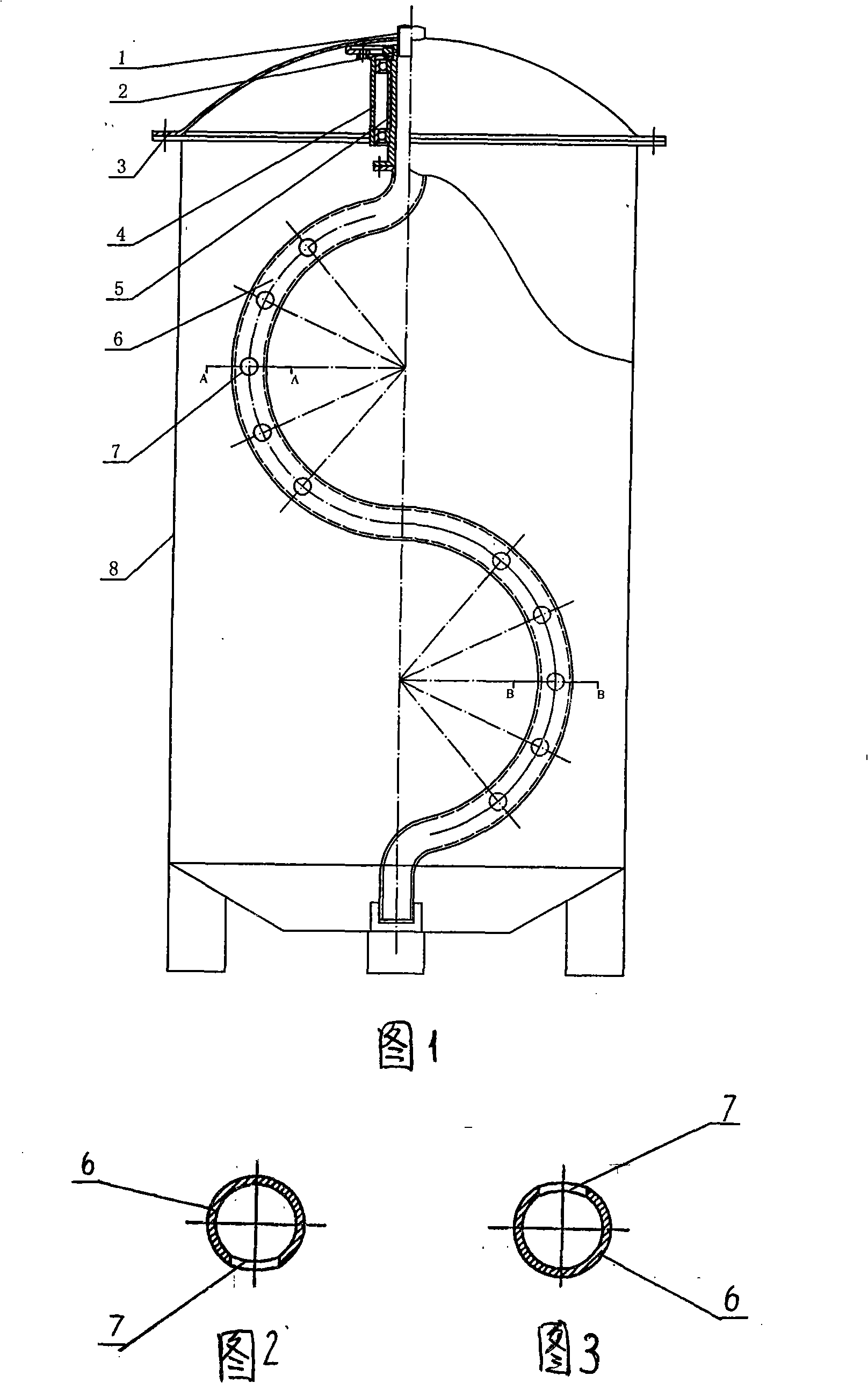

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The material liquid recoil stirring device includes a fermenter upper cover 3, a fermenter main body 8 and a bearing assembly 4, and an S-shaped tubular agitator 6 is installed in the cavity formed by the fermenter upper cover 3 and the fermenter main body 8; The casing 5 is fixed on the outer side of the upper pipe wall of the S-shaped tubular agitator 6, and is assembled in the bearing assembly 4; the feed port 1 is installed on the center of the upper cover 3 of the fermentation tank, and the feed port 1 and the S The 6 tube holes of the S-type tubular agitator are connected; on the upper half and the lower half of the S-type tubular agitator 6, there are respectively orifices 7 on the opposite side walls, and the centerline of the orifice 7 is in line with the S-shaped tubular agitator. The vertical plane of device 6 is at an angle of 90°. A sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com