LED synchronous rectifying circuit

A technology of LED circuit and synchronous rectification, which is applied in the direction of electric light source, electrical components, electroluminescent light source, etc., can solve the problems of low photoelectric conversion efficiency of LED, decrease of LED efficiency, large heat generation of LED, etc., so as to prolong life and reduce heat , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below.

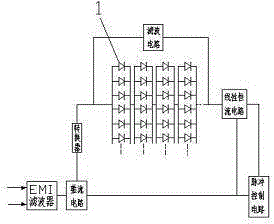

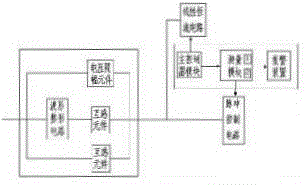

[0016] A LED synchronous rectification circuit, comprising an EMI filter, a rectification circuit, a converter, an LED circuit and a pulse control circuit, the output end of the EMI filter is connected to the rectification circuit, and the outlets of the rectification circuit are respectively connected to the converter and the The pulse control circuit is connected, the converter is connected in series with the LED circuit, the LED circuit is connected in series by several LED lamp groups, the LED lamp group is connected in parallel by several diodes, and a linear constant current is connected in series at the end of the LED circuit circuit, the linear constant current circuit is connected between the rectification circuit and the pulse control circuit.

[0017] Among them, the function of the EMI filter is to allow the frequency signal when the equipment is working normally to enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com