High-performance fat-soluble antioxidant fat-soluble tea-polyphenol and preparation method thereof

A fat-soluble tea polyphenol and a technology for tea polyphenols, which are applied in the field of high-performance antioxidant fat-soluble tea polyphenols and their preparation, can solve the problems of affecting esterification reaction, suboptimal antioxidant performance, reduced antioxidant performance, etc. problem, to achieve the effect of long induction time, excellent anti-lipid peroxidation performance, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1 fatty acid chloride preparation

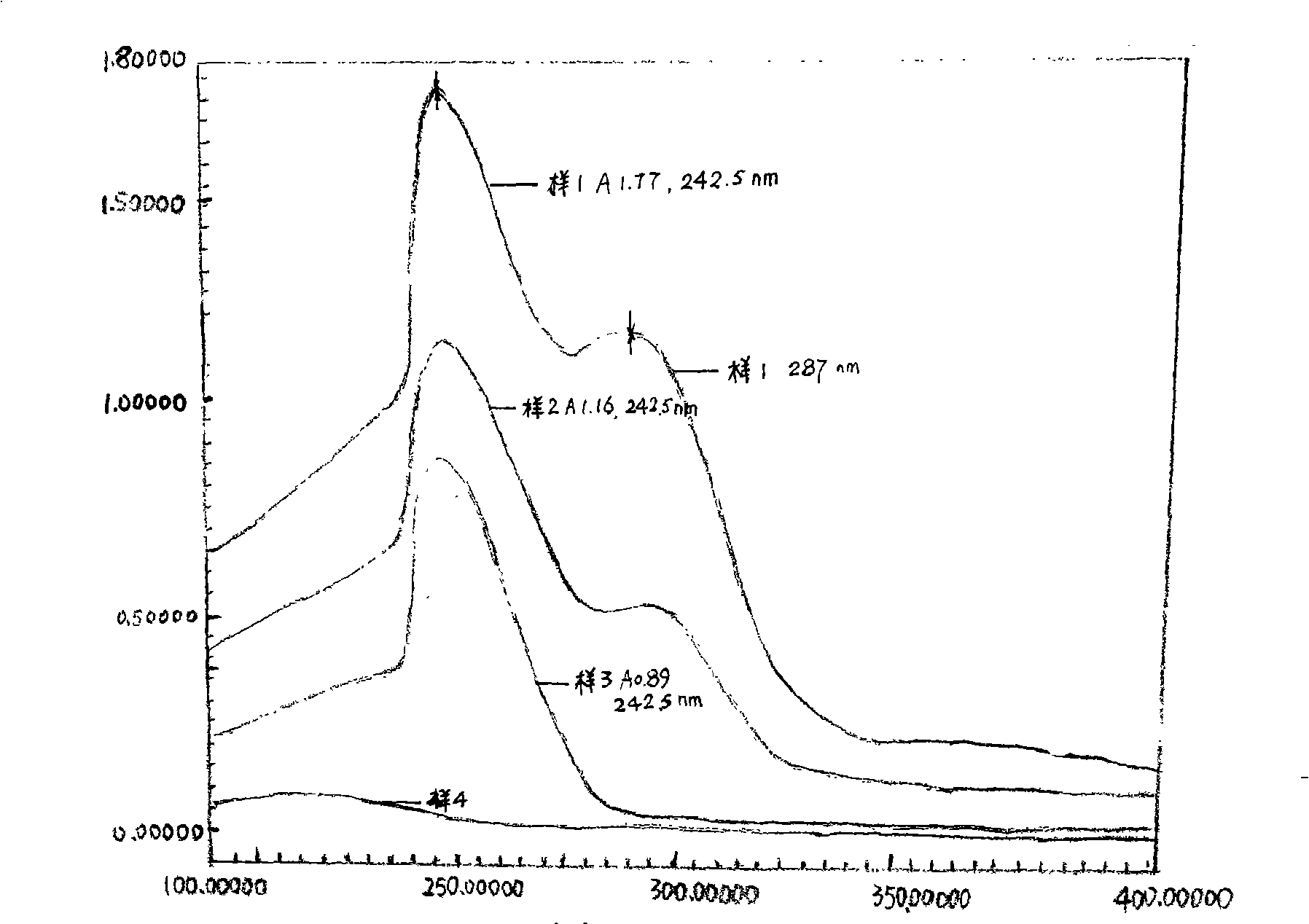

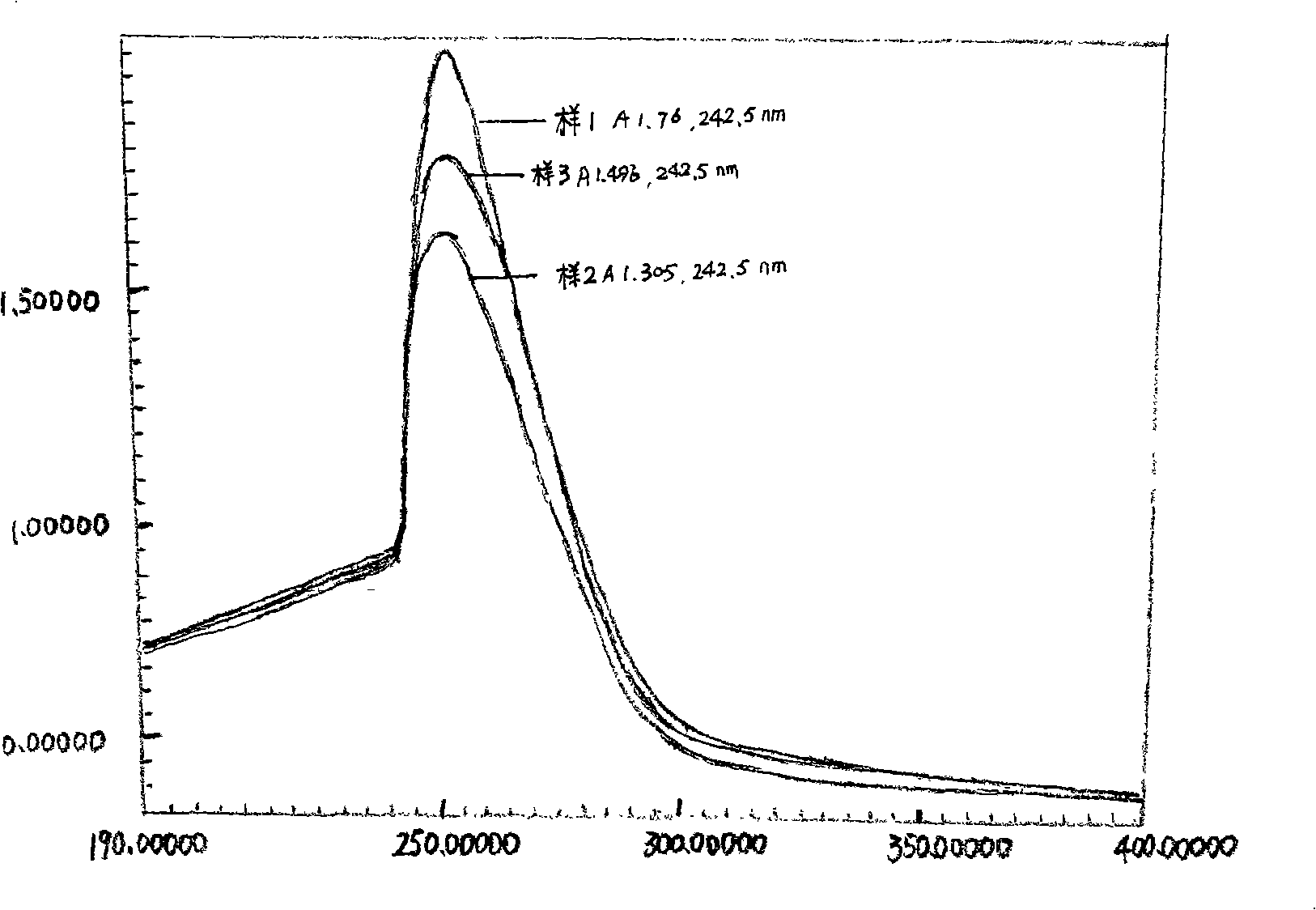

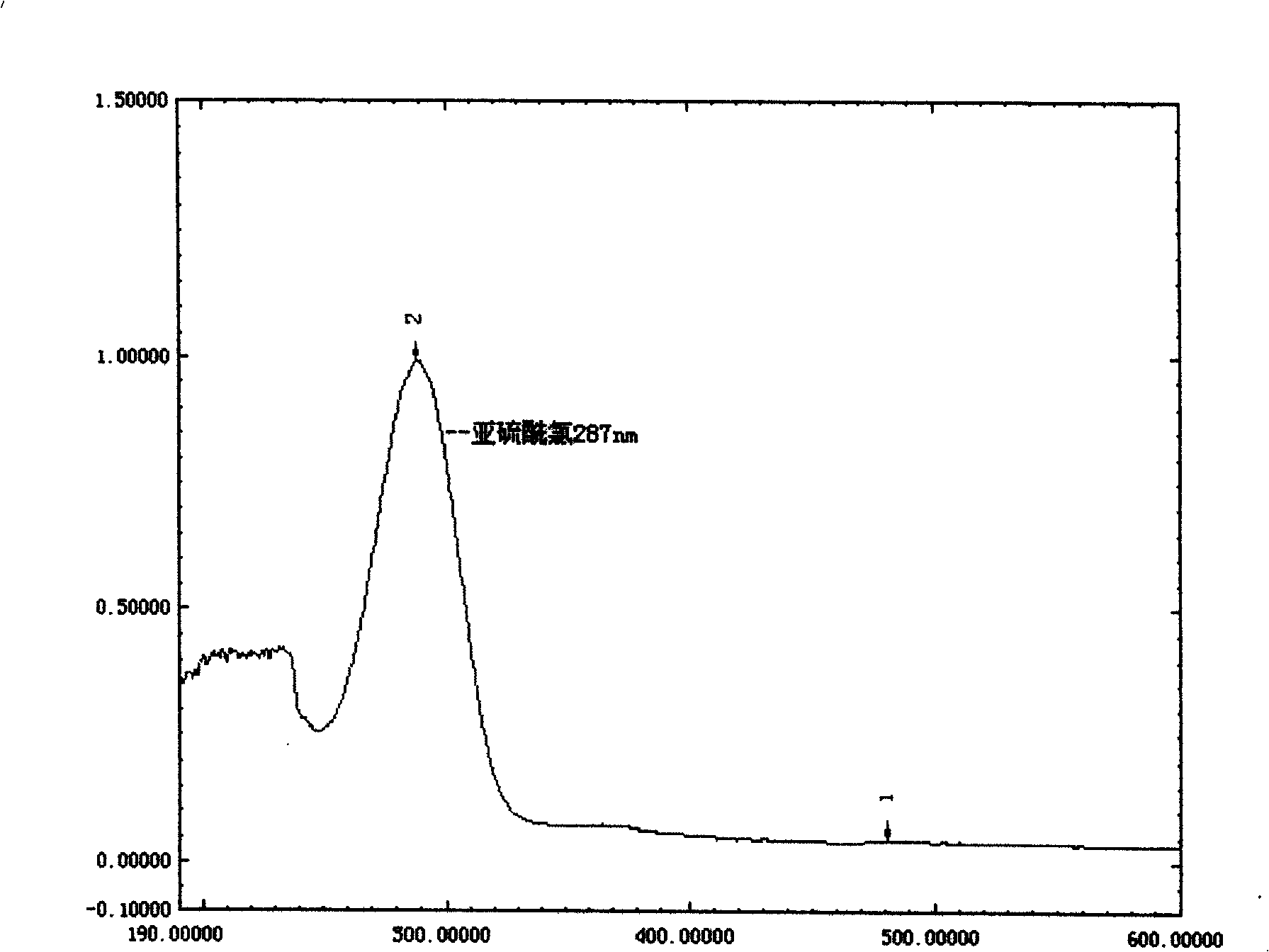

[0098]Weigh 104 grams (0.4mol) of palmitic acid, put it in a 250ml three-necked bottle (with stirring, feeding port, condenser)*, and then add 36ml (0.49mol) of thionyl chloride. Repeatedly raise and lower the temperature between 20°C and 50°C, while stirring the reaction until no bubbles are generated, add 0.62ml (0.08mol) N,N-dimethylformamide after cooling, and then repeatedly rise and fall between 20°C and 50°C Temperature, stir the reaction until no bubbles are generated, and there is no solid after cooling, and the temperature is raised and lowered repeatedly about 5 to 8 times. The reaction solution was scanned by UV (400nm-200nm), and there was no thionyl chloride peak at around 280nm**.

[0099] Weigh 10 grams (0.0245 mol) of raw material tea polyphenols (total polyphenol content 70%), add appropriate amount of 400 ethyl acetate and stir, add 7.2 grams (0.086 mol) of sodium bicarbonate, (add in 4 times) gradually ...

Embodiment 2

[0103] Embodiment 2 preparation of fat-soluble tea polyphenols

[0104] The acylating agent is prepared as above.

[0105] Weigh 10 grams (0.0245mol) of raw material tea polyphenols (total polyphenol content 95%), add an appropriate amount of 400 g ethyl acetate and stir, add 9.26 grams (0.11mol) of sodium acetate, (add in 4 times) gradually add the palmitoyl chloride prepared above 18.95ml (0.061mol), while insulated and stirred at 32°C for 9 hours, then added 200ml of dilute hydrochloric acid for shaking, left to stand, and separated into layers. Separate, wash the organic layer twice with water, concentrate the organic layer in vacuo, recover ethyl acetate to dryness, add 90% ethanol solution, put it in a separatory funnel, and extract twice 80ml×2 times with petroleum ether, separate the ethanol layer, vacuum Concentrate, recover ethanol, and dry to obtain a solid product, which is light brown to light yellow powder.

[0106] Raw materials: palmitoyl chloride: sodium bic...

Embodiment 3

[0107] Embodiment 3 preparation of fat-soluble tea polyphenols

[0108] The acylating agent is prepared as above.

[0109] Weigh 10 grams (0.0245mol) of raw material tea polyphenols (total polyphenol content 40%), add appropriate amount of 400 ethyl acetate and stir, add 8.23 grams (0.098mol) of sodium bicarbonate, (add in 4 times) gradually add the above-mentioned prepared palm Acyl chloride 15.16ml (0.049mol), while insulated and stirred at 45°C for 8 hours, then added 200ml of dilute hydrochloric acid to shake, let stand, and separate layers. Separate, wash the organic layer twice with water, concentrate the organic layer in vacuo, recover ethyl acetate to dryness, add 90% ethanol solution, put it in a separatory funnel, and extract twice 80ml×2 times with petroleum ether, separate the ethanol layer, vacuum Concentrate, recover ethanol, and dry the solid to obtain the product, which is light brown to light yellow powder.

[0110] Raw materials: palmitoyl chloride: sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com