Method for synthesizing ethyl acetate by ionic liquid catalytic continuous esterification distillation

An ionic liquid, ethyl acetate technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc. The effect of intensifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

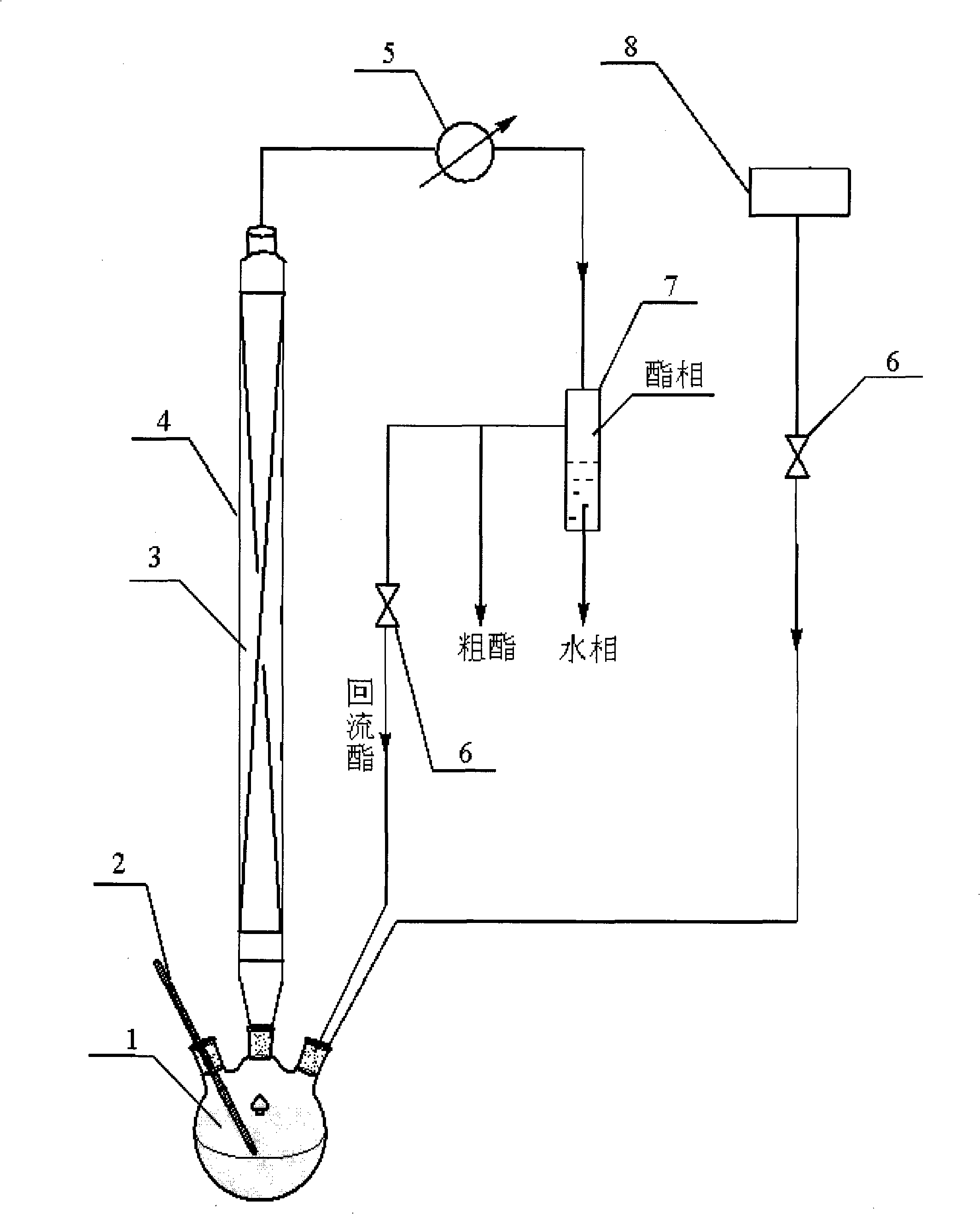

Image

Examples

Embodiment 1

[0030] Reactive distillation experimental device used: glass tower body (Φ20mm), built-in Φ2×2mm stainless steel θ mesh ring packing, packing height is 1.4m, insulation sleeve diameter is 60-80mm, kettle volume is 500ml.

[0031] Add 2.00 mol of glacial acetic acid, 0.33 mol of ethanol and 0.01 mol of ionic liquid α-pyrrolidone bisulfate into the reaction kettle, set the temperature of the kettle at 110°C, keep the bottom at 95°C, and keep at the top at 70.4°C. Raise the temperature and heat up, and make it fully reflux for 15 minutes after the reflux liquid appears at the top of the tower, then continuously add the mixture of ethanol and acetic acid prepared in advance with an alkyd molar ratio of 1.05:1 into the esterification tank through the head tank, and start The reflux ratio is continuously carried out for the synthesis of ethyl acetate. The feed flow rate of the mixed raw materials is 40ml / h, the reflux ratio is 1, and the reflux ester flow rate is 35mL / h. The ester ...

Embodiment 2

[0033] Reactive distillation experimental device used: glass tower body (Φ20mm), built-in Φ2×2mm stainless steel θ mesh ring packing, packing height is 1.4m, insulation sleeve diameter is 60-80mm, kettle volume is 500ml.

[0034] Add 2.00 mol of glacial acetic acid, 0.67 mol of ethanol and 0.2 mol of ionic liquid α-pyrrolidone bisulfate into the reaction kettle, set the temperature of the kettle at 100°C, keep the bottom at 90°C, and keep at the top at 71°C. Raise the temperature and heat until there is a reflux liquid at the top of the tower, let it fully reflux for 15 minutes, then add the mixture of ethanol and acetic acid with a molar ratio of alkyd to 1.2:1 to the esterification tank continuously through the head tank, and start the process at the same time. The reflux ratio is continuously carried out for the synthesis of ethyl acetate. The feed flow rate of the mixed raw materials is 20ml / h, the reflux ratio is 4, and the reflux ester flow rate is 20mL / h. The ester con...

Embodiment 3

[0036] Reactive distillation experimental device used: glass tower body (Φ20mm), built-in Φ2×2mm stainless steel θ mesh ring packing, packing height is 1.4m, insulation sleeve diameter is 60-80mm, and the volume of the kettle is 500ml.

[0037] Add 2.00 mol of glacial acetic acid, 0.33 mol of ethanol and 0.6 mol of ionic liquid α-pyrrolidone bisulfate into the reaction kettle, set the temperature of the kettle to 110°C, keep the bottom at 95°C, and keep at the top at 70°C. Raise the temperature and heat up, and make it fully reflux for 15 minutes after the reflux liquid appears at the top of the tower, then continuously add the mixture of ethanol and acetic acid prepared in advance with an alkyd molar ratio of 1:1 into the esterification tank through the head tank, and start the process at the same time. The reflux ratio is continuously carried out for the synthesis of ethyl acetate. The feed flow rate of the mixed raw materials is 40ml / h, the reflux ratio is 1, and the reflux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com