Hollow fiber film assembly, film bioreactor and water treatment device

A fiber membrane and fiber membrane bundle technology, which is applied in the field of water treatment, can solve the problems of loss of effective filtration area of filtration non-uniformity, difficult to remove, and sludge accumulation at the root of hollow fiber membrane filaments. Easy to deposit and stay, avoid siltation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

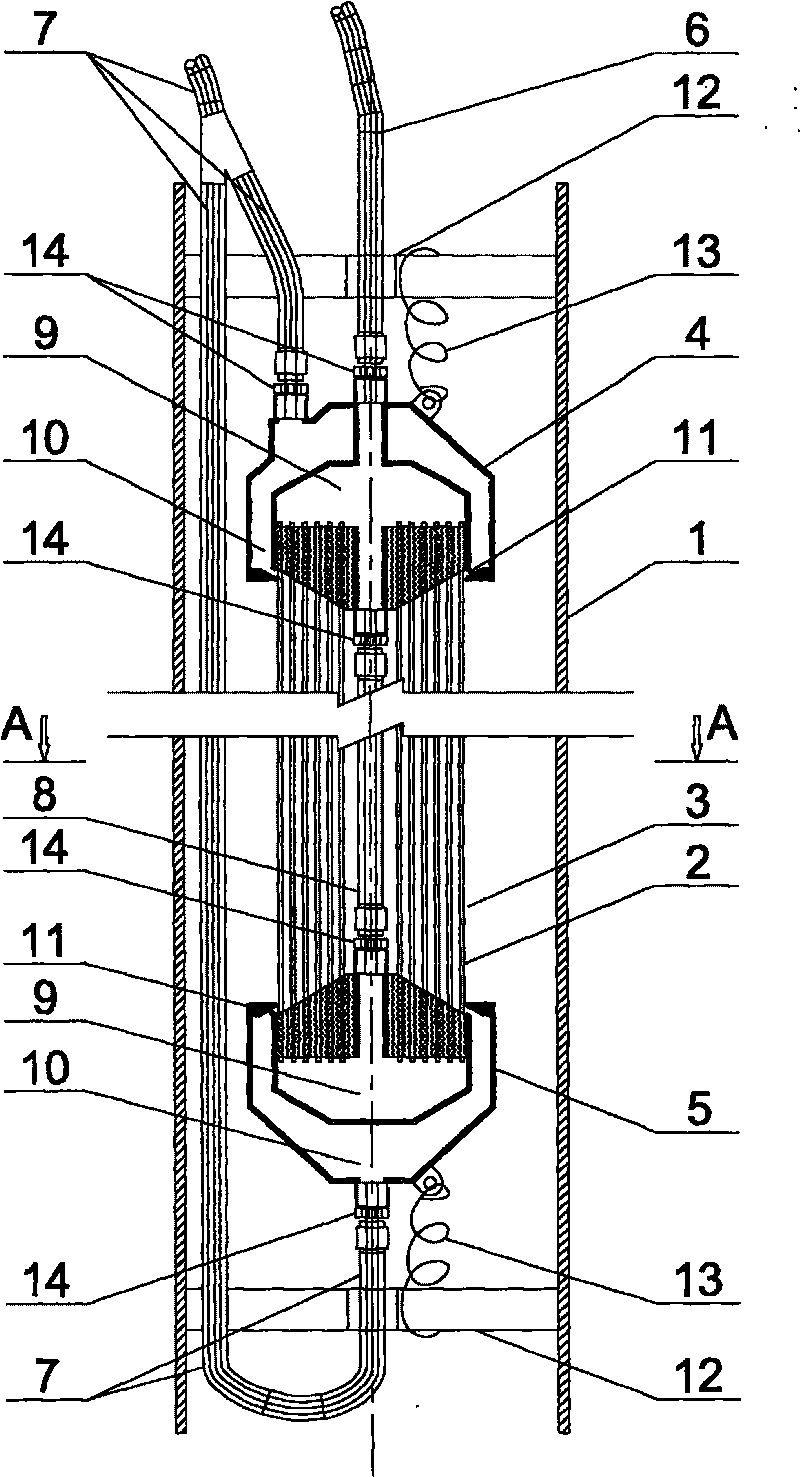

[0059] Such as figure 1 , image 3 As shown, a hollow fiber membrane module includes a housing 1 with an inner diameter of 90 mm and a material made of UPVC (un-plasticized polyvinyl chloride) plastic, and a hollow fiber composed of 300 hollow fiber membrane filaments 2 arranged in the housing 1 Membrane bundle 3, the average pore diameter of the micropores of the hollow fiber membranes 2 for passing liquid is 0.1 μm, the outer diameter of the hollow fiber membranes is 1.35 mm, the material is polyvinylidene fluoride, and the two ends are casted and collected with epoxy resin In the upper end 4 and the lower end 5, and use polyurethane to carry out secondary casting to protect the root of the membrane. The overall shape of the upper end 4 and the lower end 5 is cup-shaped, and the diameter of the upper circle is 60 mm. Both the upper end head 4 and the lower end head 5 are provided with a water production collection chamber 9, and the two ends of the hollow fiber membrane fi...

Embodiment 2

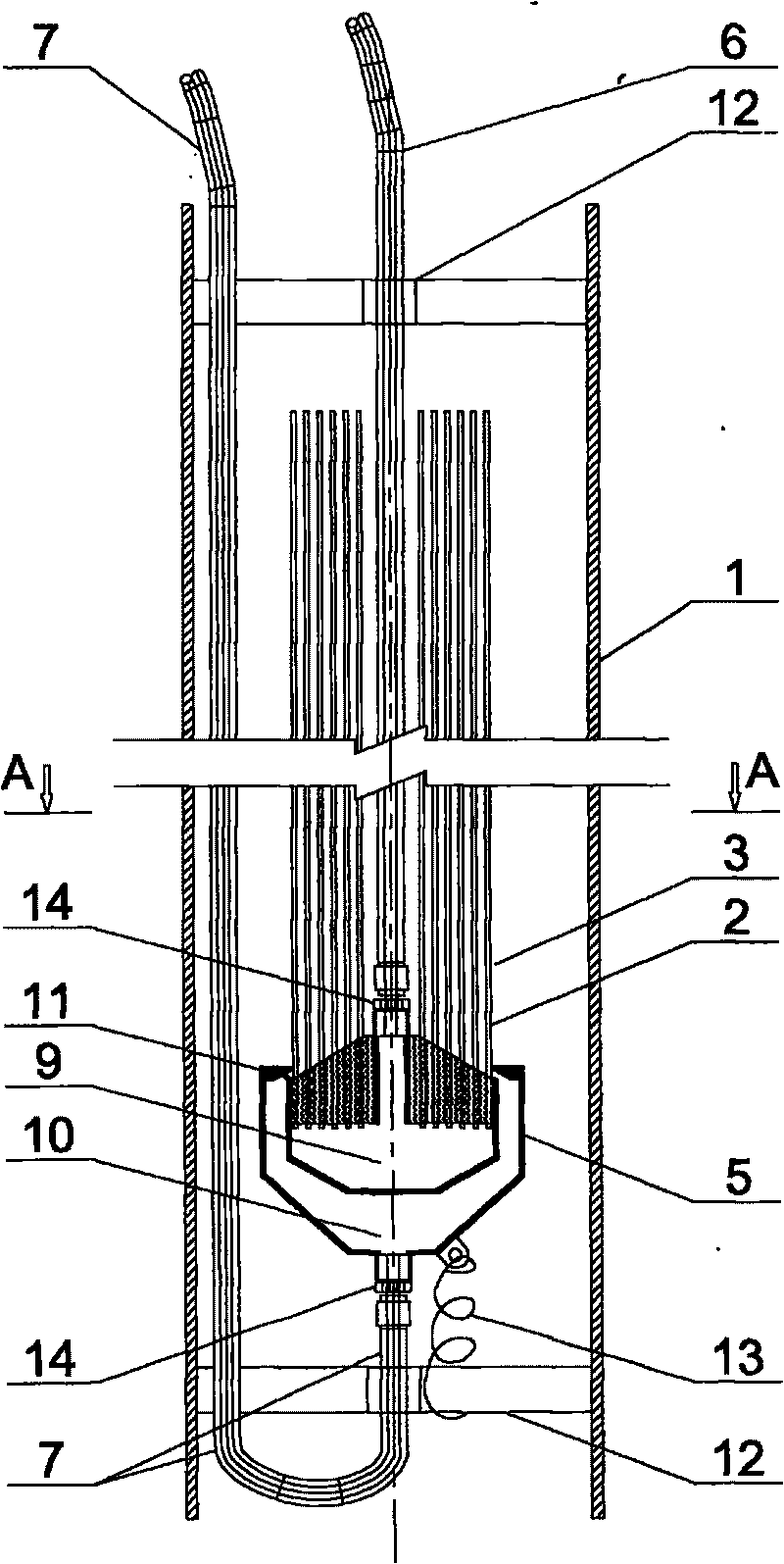

[0067] Such as figure 2 , Figure 4 As shown, a hollow fiber membrane module includes a shell 1 with an inner diameter of 90 mm and a material made of UPVC plastic, a hollow fiber membrane bundle 3 composed of 180 hollow fiber membrane filaments 2 arranged in the shell 1, and a hollow fiber membrane The average pore diameter of the micropores of the filament 2 for passing liquid is 0.1 μm, the outer diameter of the hollow fiber membrane is 1.35 mm, the material is polyvinylidene fluoride, the upper end can swing freely, and each membrane filament is in a closed-pore state. Sealed with flexible epoxy resin, the lower end is poured with epoxy resin and collected in the lower end 5, and it is re-cast with polyurethane to protect the root of the membrane. The overall shape of the lower end 5 is cup-shaped, and the upper cross-section is a square with a side length of 50 mm. The hollow fiber membrane filament 2 is in a perforated state in the water production collection chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com