Wear assembly for excavating machines

A wear-resistant and assembly technology, applied in earth movers/excavators, construction, etc., can solve problems such as high stress and difficult manufacturing, and achieve long service life, easy manufacturing, and simple replacement procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

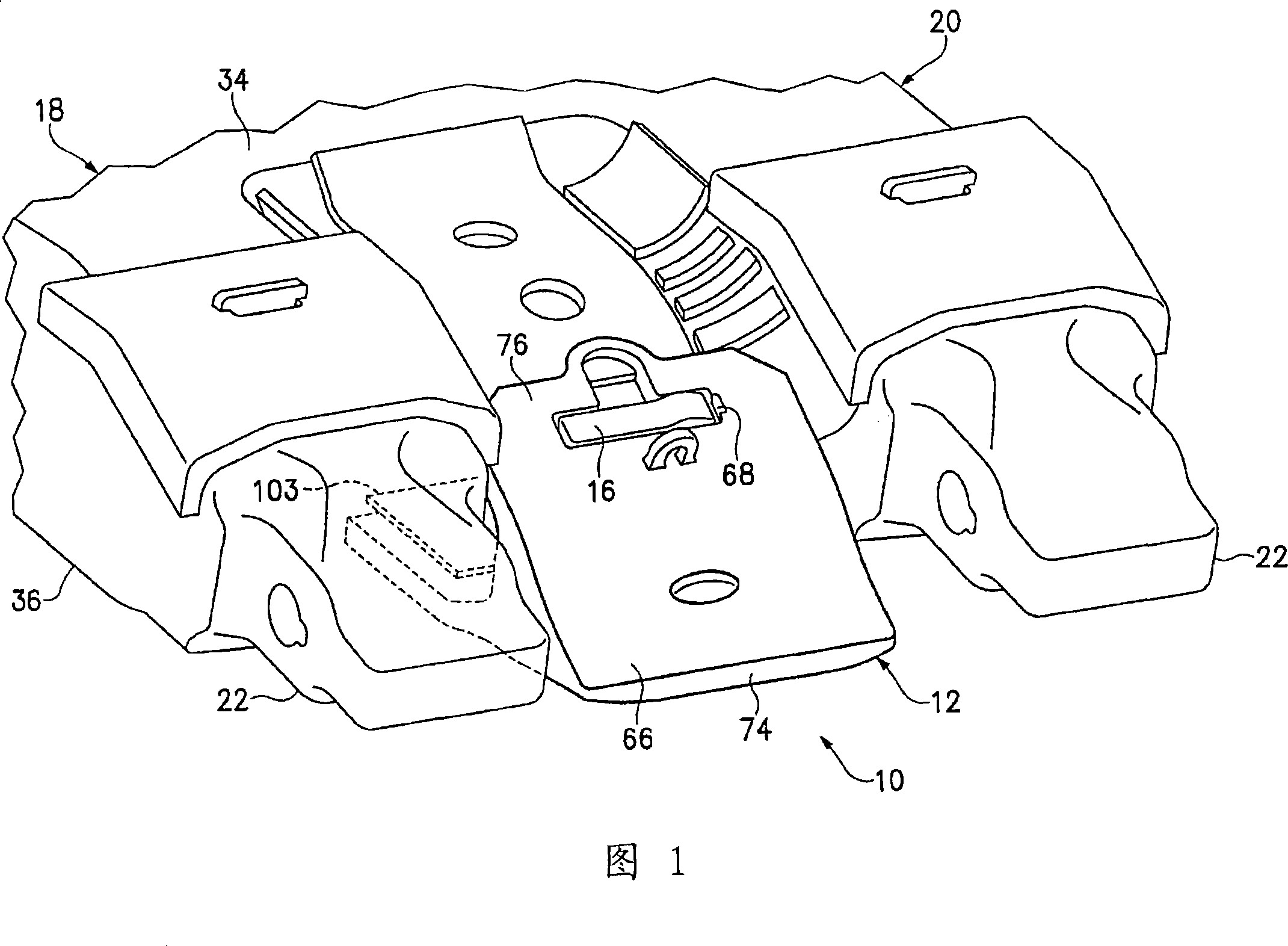

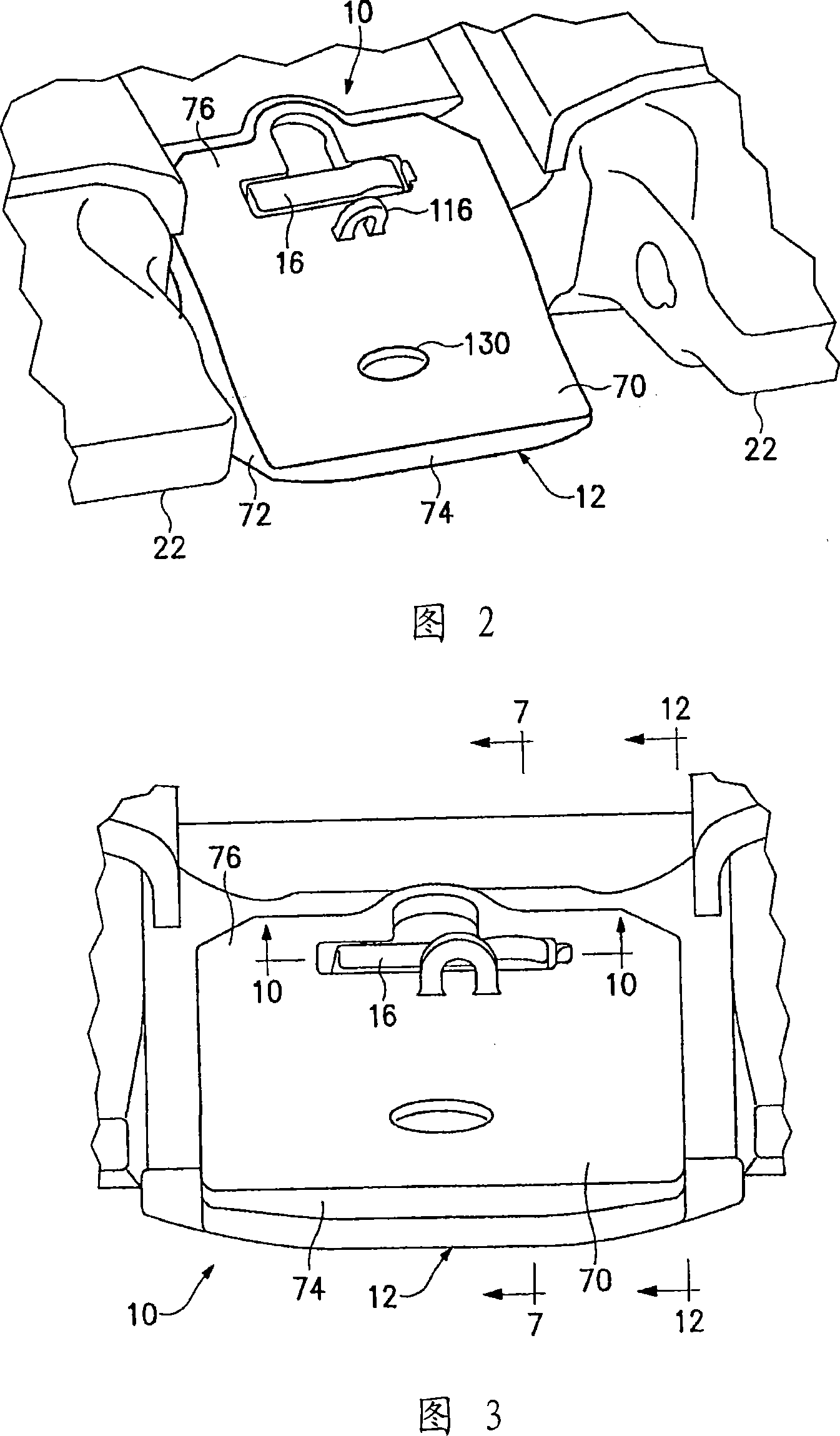

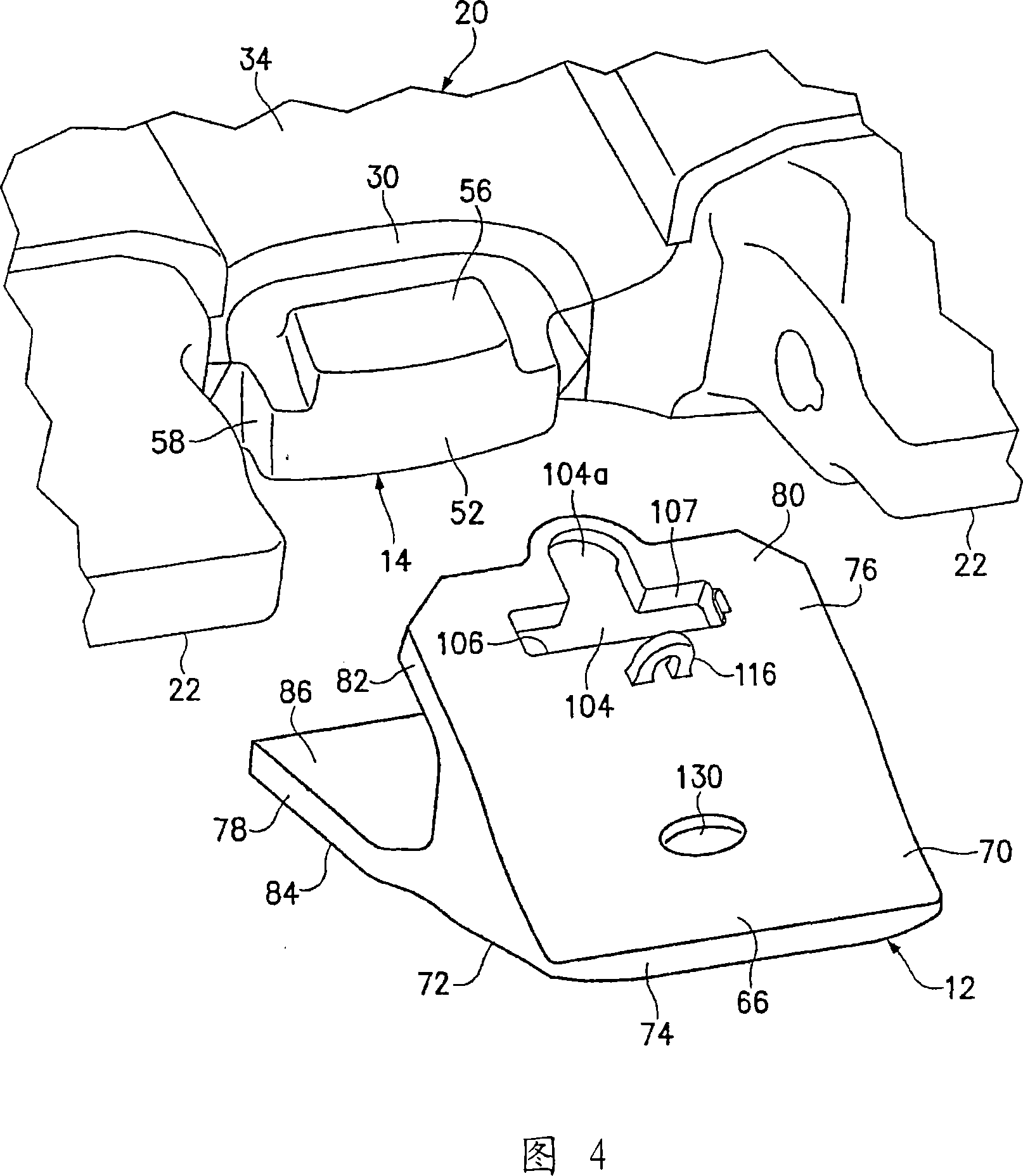

[0029] The present invention relates to a wear-resistant assembly for protecting the excavating edge of an excavator such as the lip of an excavating bucket, and although the assembly is particularly suitable for joining a shroud to a lip, the present invention The concepts can be applied in joining other wear resistant components such as joints, joints, wings, etc. to bucket lips or other excavating equipment. For ease of illustration, this application describes the assembly of the present invention in terms of a shroud mounted on a bucket.

[0030] A wear assembly 10 of an embodiment of the present invention includes a shroud-like wear member 12, a base or support structure 14, and a lock member 16 (FIGS. 1-7). A shroud is a wear resistant member that fits over the leading edge 17 of an excavating bucket 18 between the excavating teeth to protect the bucket lip 20 and to direct material such as earth into the bucket. Figure 1 shows an example of a lip 20 including a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com