Trichoderma reesei cultivation method for improving yield of cellulase

A technology of Trichoderma reesei and cellulase, applied in the field of microbial cultivation in biochemistry, can solve the problems of inhibition, microbial growth and toxicity, etc., and achieve the effect of improving the enzyme activity of filter paper and shortening the enzyme production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Trichoderma reesei fixed aeration and mass production of cellulase

[0023] Trichoderma reesei liquid activation medium is: 6g glucose, 0.6g peptone, 0.6mL Mandels trace elements, 60mL Mandels nutrient salt, 30mL citric acid buffer with a concentration of 1mol / L, add 510mL distilled water, and distribute them in a conical Sterilized in bottle.

[0024] Trichoderma reesei enzyme production medium is: glucose 6g, sulfate pulp 60g (dry weight), ammonium sulfate 13.2g, urea 3g, potassium dihydrogen phosphate 12g, calcium chloride 1.8g, magnesium sulfate 1.8g, 6mL of Mandels Trace elements, add water until the total liquid volume is 6L, and heat up to 100 ℃ for sterilization.

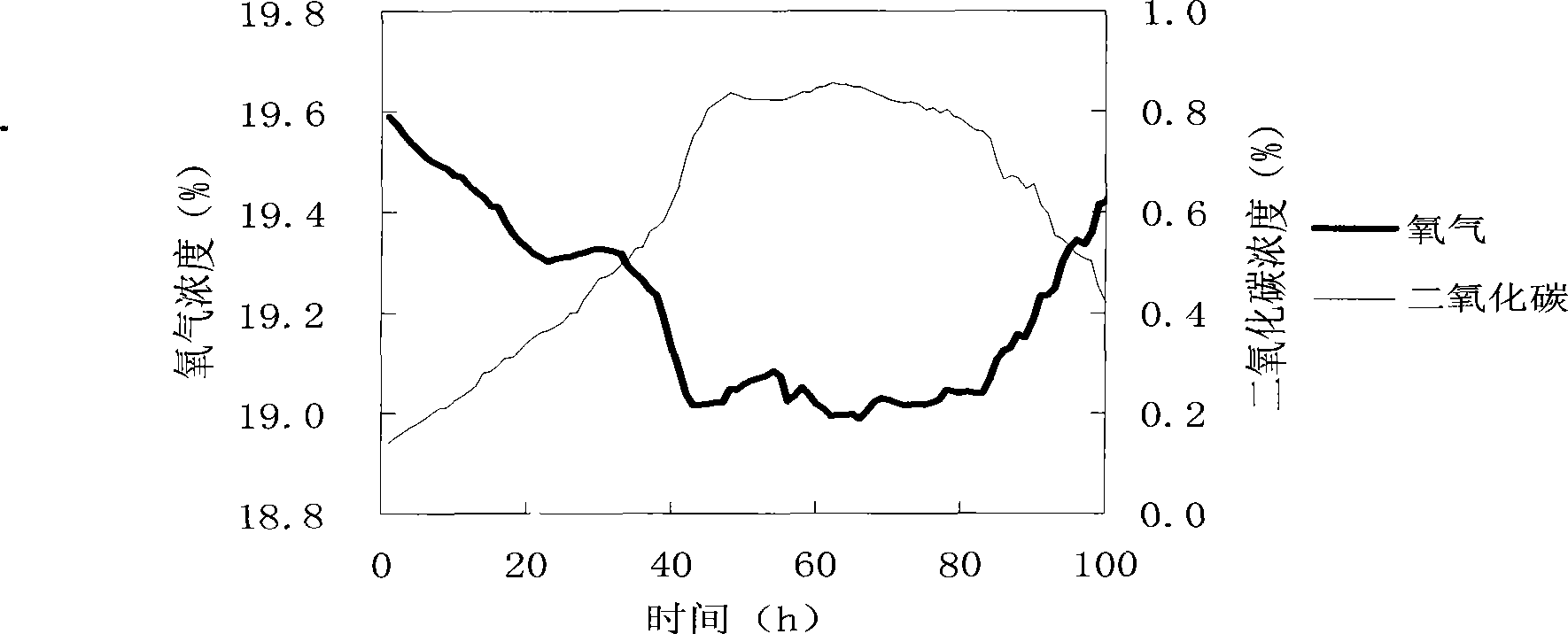

[0025] The Trichoderma reesei species was inserted into 50mL liquid activation medium, cultivated for 36h in a constant temperature oscillator at 26-32°C, 150-250r / min, and connected to a 10L fermenter at 1:10, with a liquid filling volume of 6L and ventilation. Cellulase is prepared by c...

Embodiment 2

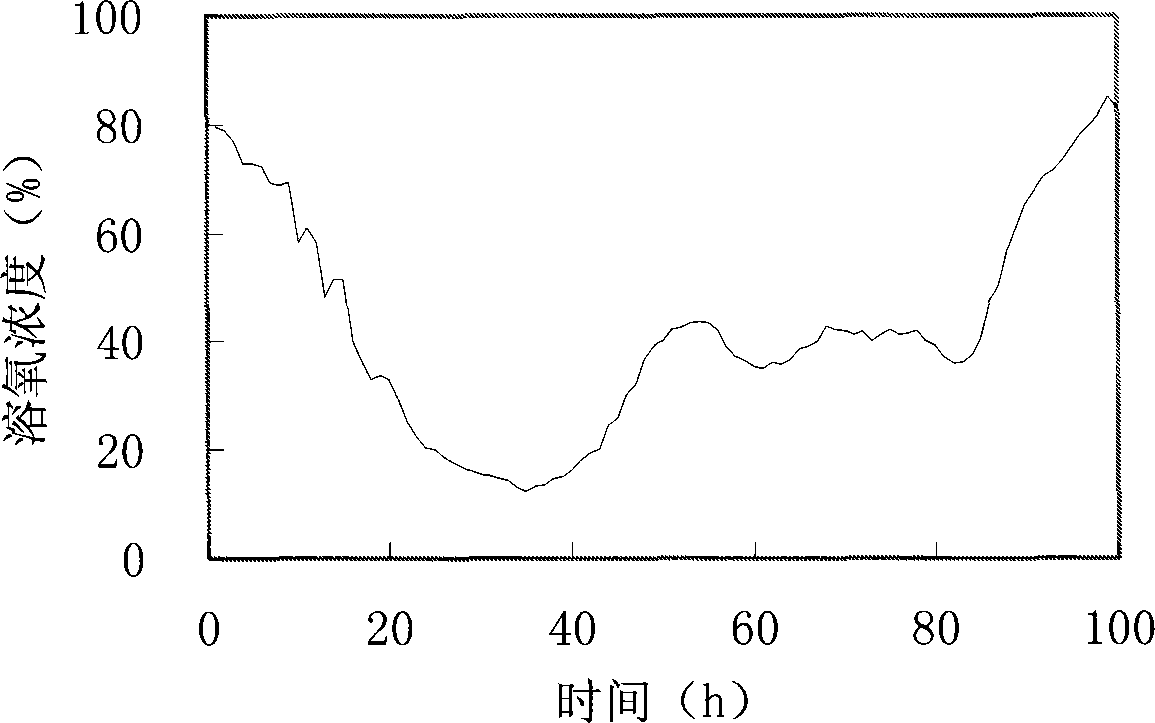

[0029] Example 2: Trichoderma reesei regulates ventilation and mass-produces cellulase

[0030] Except for the ventilation rate, other conditions are the same as those in Example 1. The ventilation volume is controlled at 10vvh at the beginning, and the change of dissolved oxygen concentration is monitored. When the dissolved oxygen concentration drops to 20%, the ventilation volume is increased, and when the dissolved oxygen concentration rises to 30%, the ventilation volume is reduced. The dissolved oxygen concentration will rise in the later stage of enzyme production, and the ventilation volume should be reduced until it drops to 10vvh.

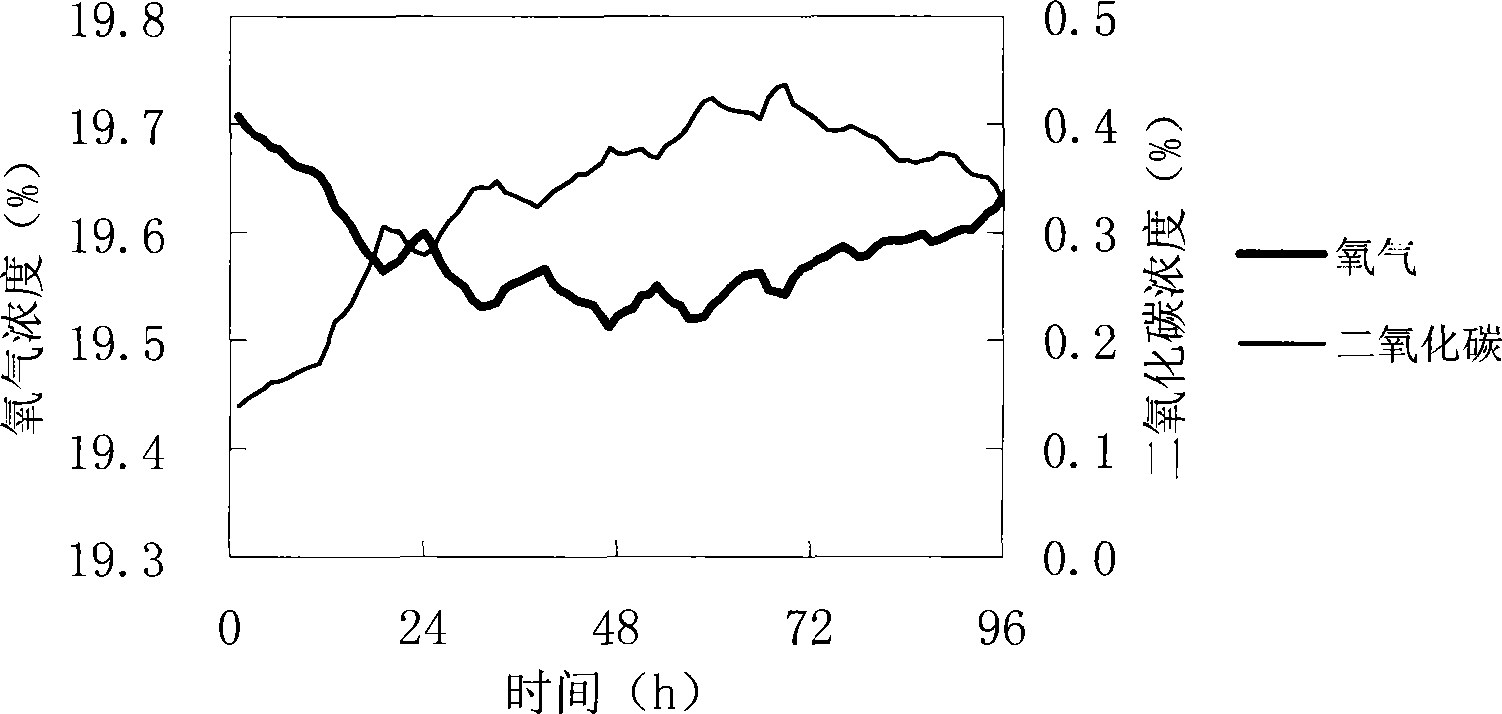

[0031] The oxygen and carbon dioxide concentrations in the exhaust gas were measured during the production of enzymes. image 3 shown. The highest carbon dioxide concentration in the exhaust gas is about 0.4%, which is only half of that of Example 1, which is beneficial to the growth and metabolism of mycelium.

[0032] The adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com