Plate blade thrusting unit for flying vehicle

A technology for a thrust device and an aircraft, which is applied in the aviation field, can solve the problems of adverse effects on the safety and efficiency of the aircraft, difficult processing and manufacturing, and large resistance of the aircraft, and achieves the effects of simple structure, high safety and maneuverability, and flexible maneuvering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

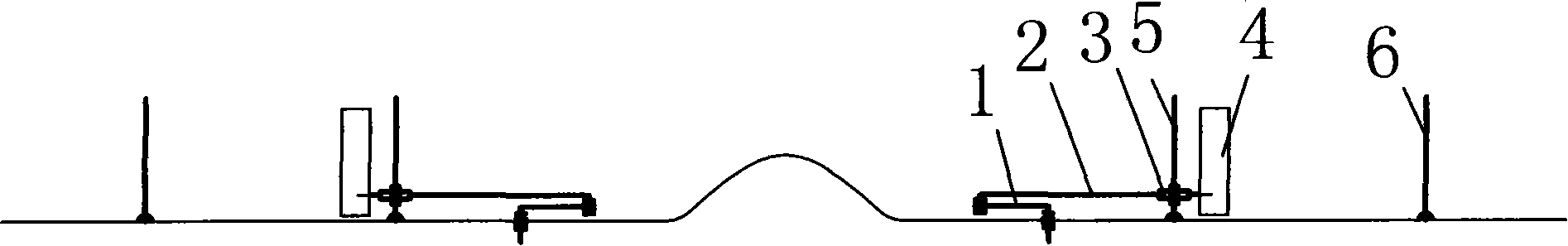

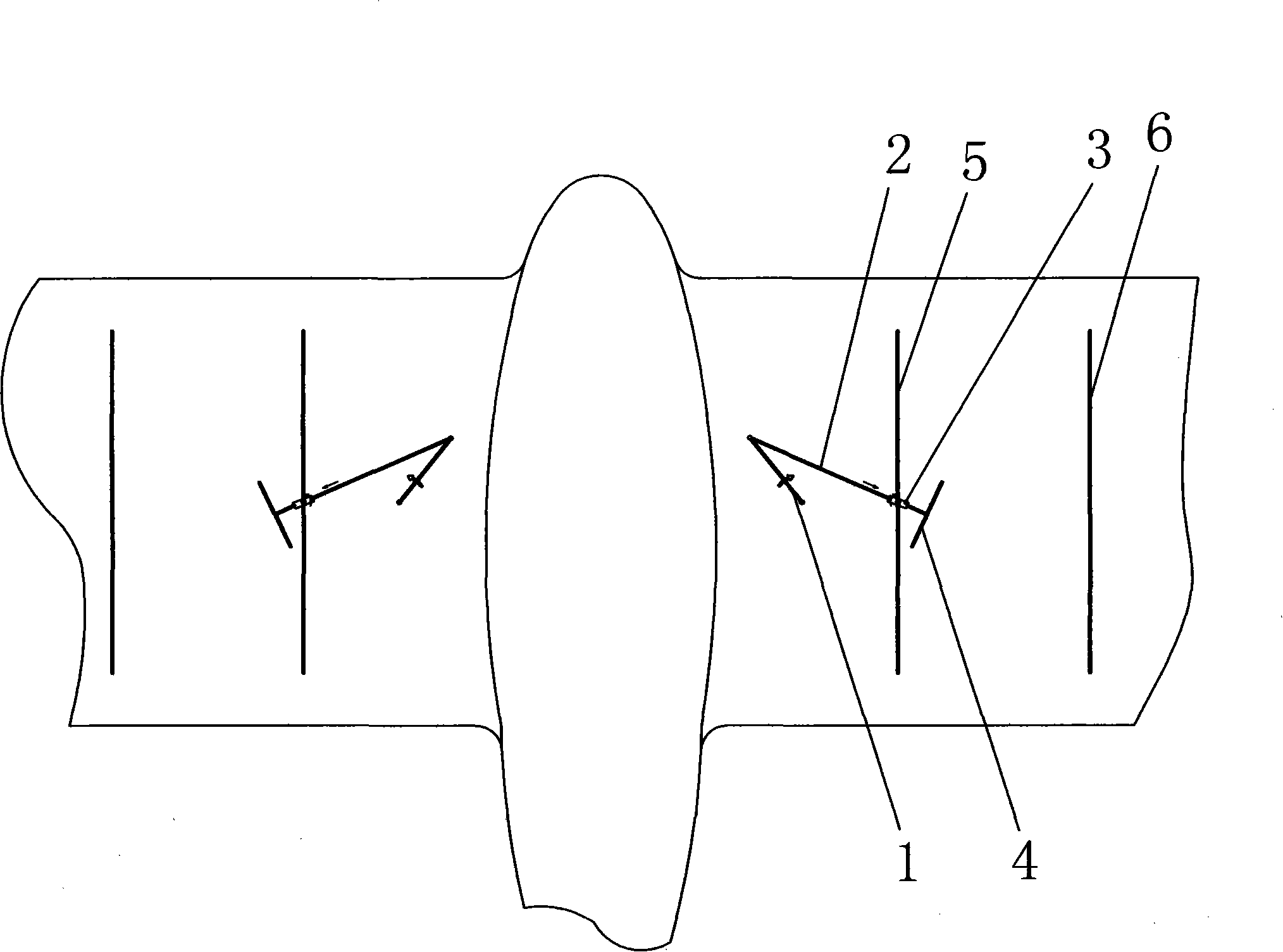

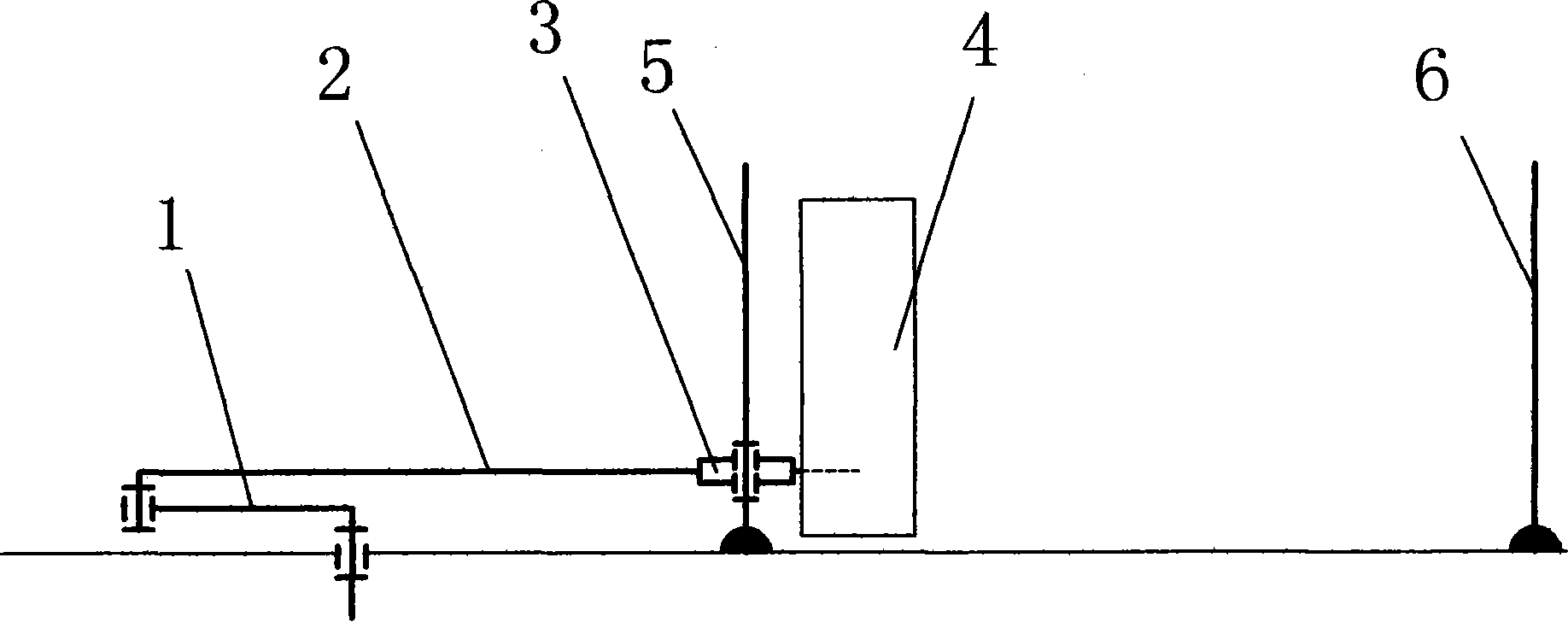

[0013] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] refer to figure 1 , figure 2 , image 3 and Figure 4 , the flat plate blade thrust device for aircraft of the present invention has two identical parts that are left and right symmetrical relative to the longitudinal symmetry plane of the aircraft, and are installed on the upper surface of the left and right wings of the aircraft respectively, and each part is guided by a crank 1, a connecting rod 2, and a connecting rod. One end of the connecting rod 2 is vertically fixed to the lower middle position of the flat blade 4, and the other end of the connecting rod 2 passes through the connecting rod guide 3 and the crank 1 is connected, the connecting rod guide 3 is loosely installed in the middle position of the lower part of the inner fixed plate 5, the vertical center axis of the connecting rod guide 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com