Modular energy feedback type traction power set and control method

A technology of energy feedback and traction power supply, which is applied in the direction of output power conversion devices, electrical components, power lines, etc., can solve the problems of large harmonic pollution of the AC power grid, failure of energy feedback, and unfavorable light weight of vehicles, etc., to improve power supply Reliability, improved system reliability, and ease of modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

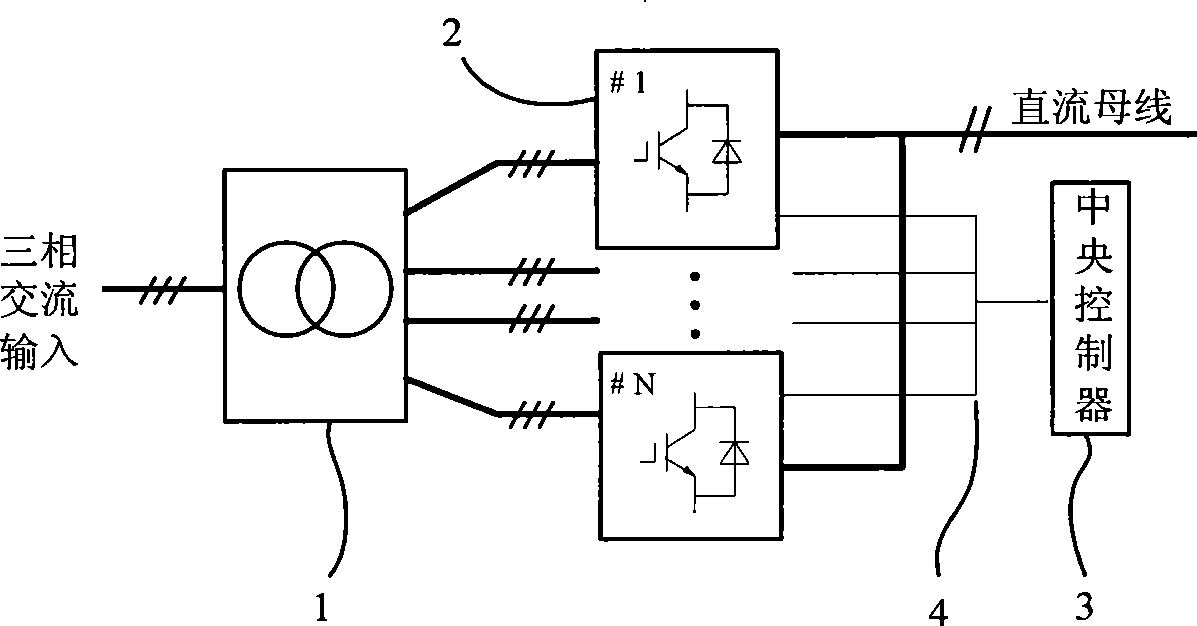

[0021] The present invention proposes a modularized energy feedback type traction power supply device, which includes:

[0022] A multi-winding transformer 1, the transformer is composed of a primary winding and a plurality of secondary windings, the primary winding is connected to the AC power grid, and a star connection is adopted, each secondary winding is connected to a PWM rectifier unit, and the connection of each secondary winding In the same way, they all adopt triangle connection;

[0023] A plurality of PWM rectifier units 2, the DC outputs of all rectifier units are connected in parallel to the DC bus as the total output of the power supply device;

[0024] A central controller 3, which is interconnected with each PWM rectifier unit through a CAN network 4.

[0025] The central controller includes a DC voltage sensor and a CPU board, and the CPU board contains a digital signal processor and a CAN communication interface.

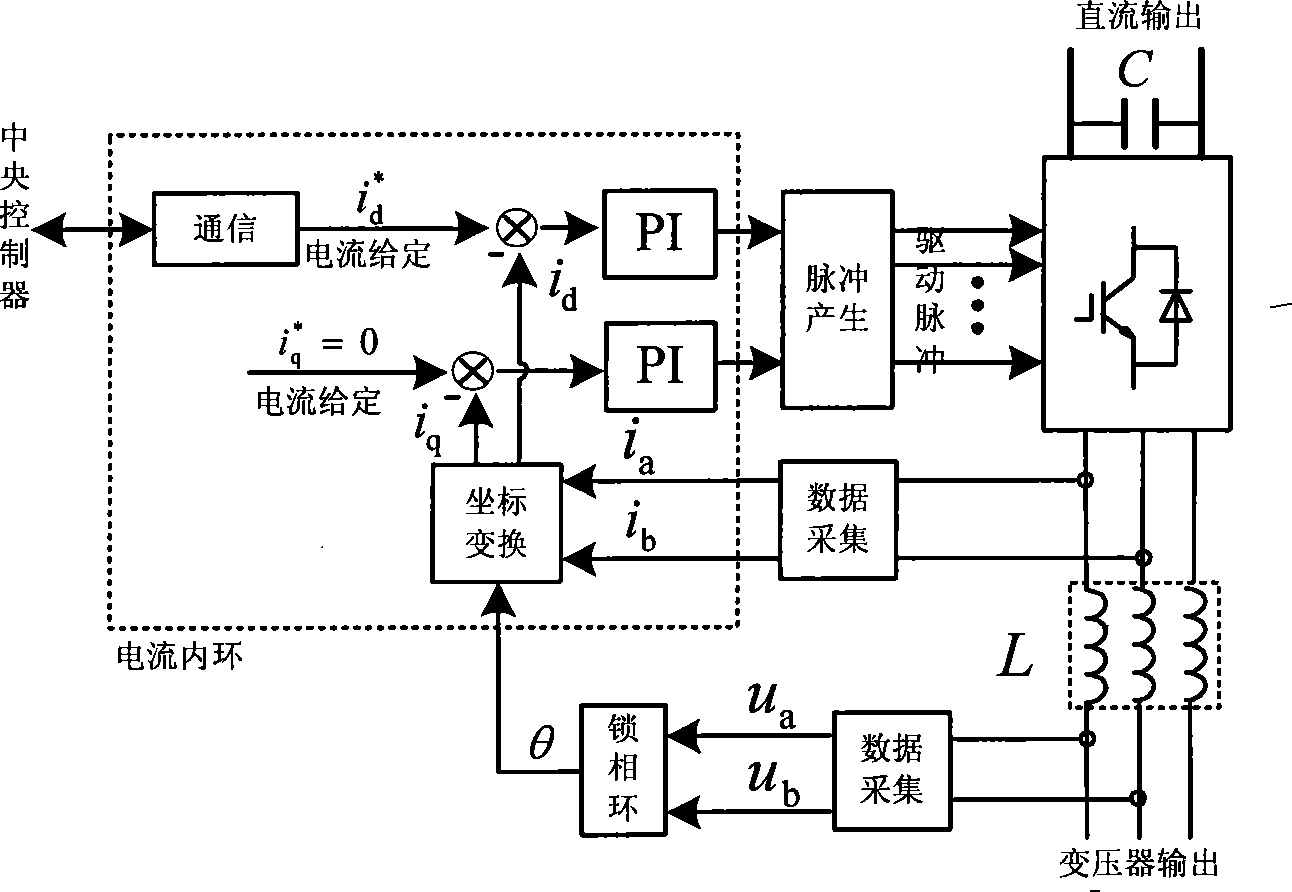

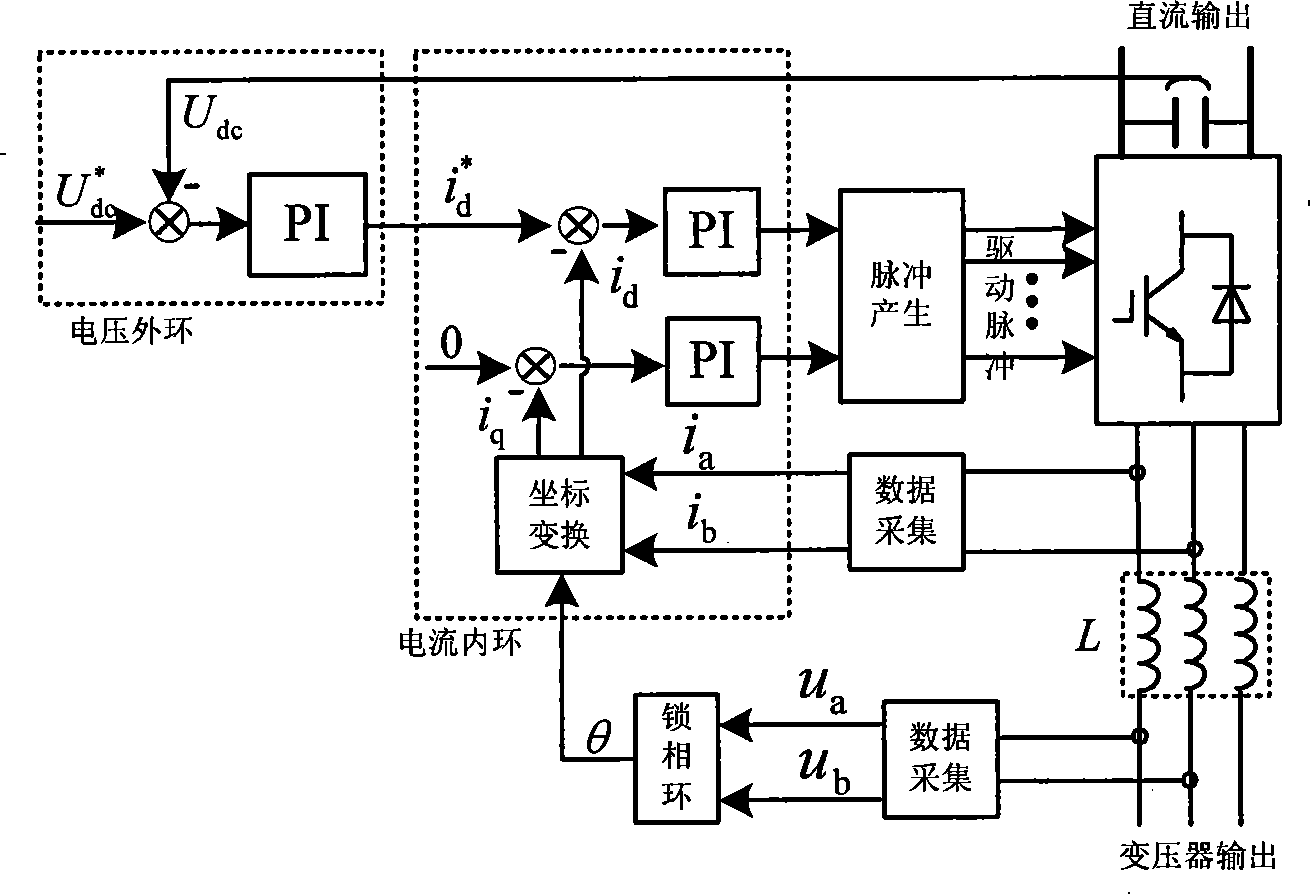

[0026] The power switch tubes in each PWM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com