Train carriage bolster integral core box group, bolster sand core and its processing method

A processing method and integral core technology, applied in the direction of metal processing equipment, cores, manufacturing tools, etc., can solve the problems of shortening processing time, disadvantages, and inability to make two sand cores in parallel, and achieve dimensional accuracy, which is easy to control and shortens processing time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

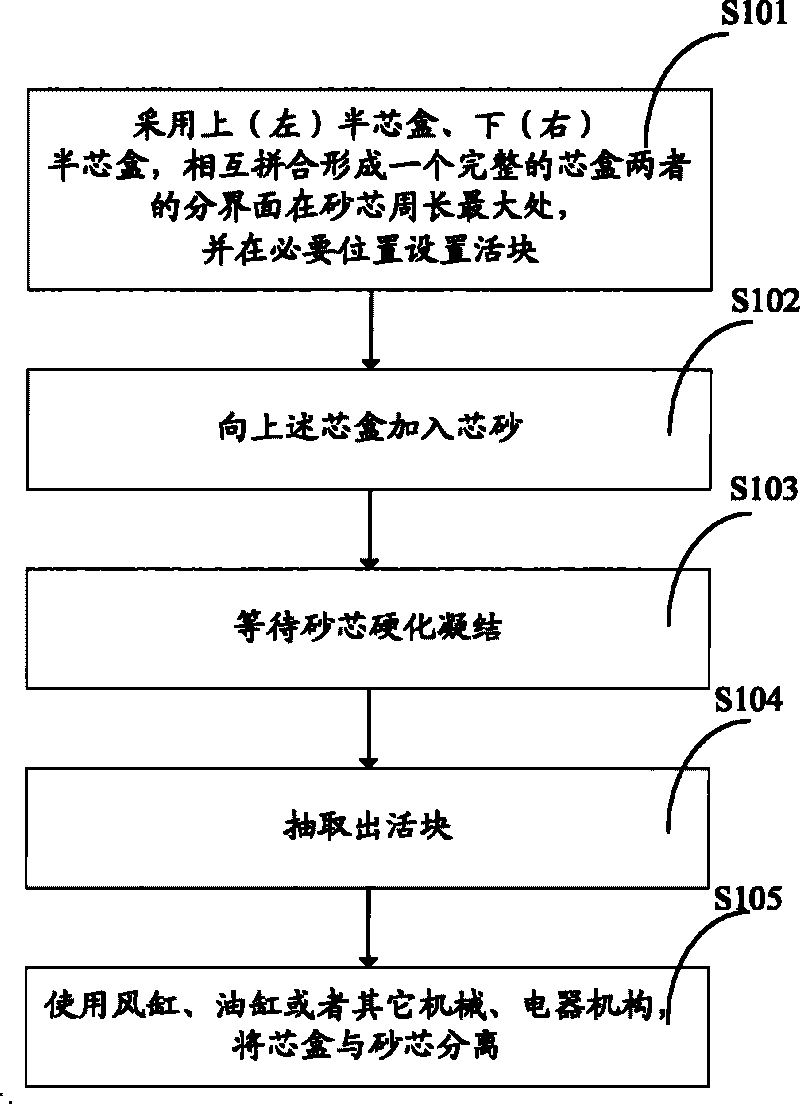

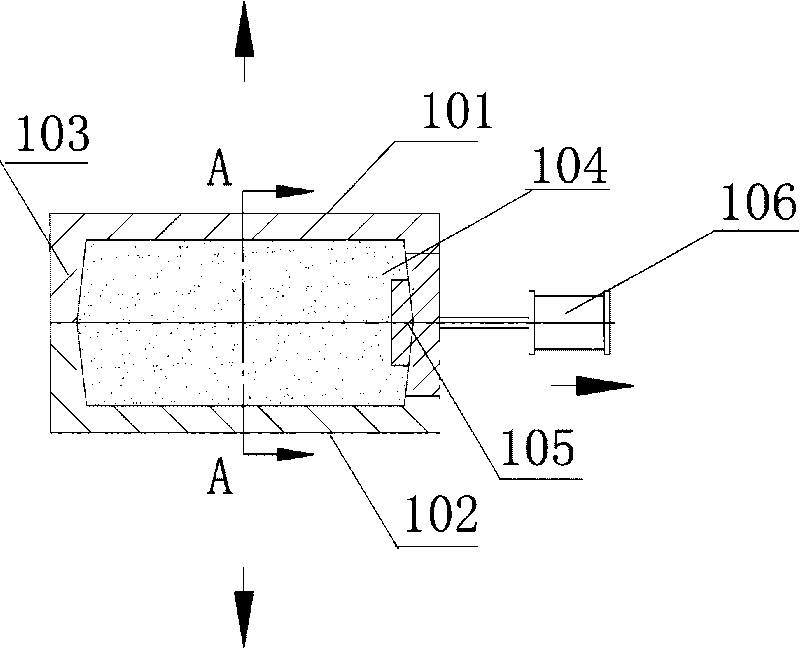

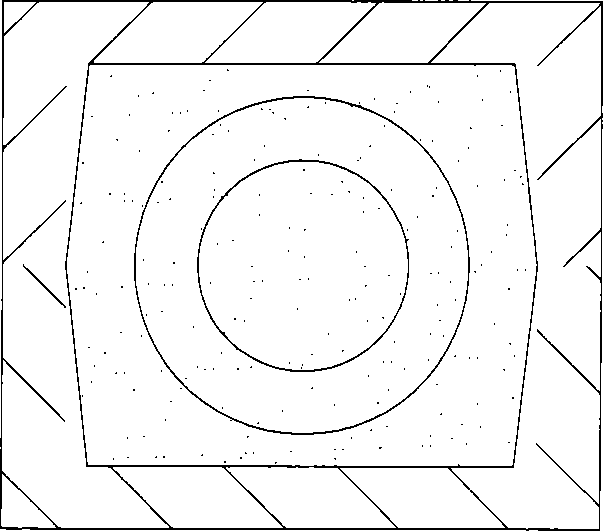

[0048] Please see figure 1 , which shows the principle flow of the bolster manufacturing method provided by the present invention. Please combine figure 2 , this figure is a schematic diagram of the overall core provided by the present invention; please also refer to image 3 , the figure is figure 2 A-A to the sectional view. The basic principles of the present invention are described below in conjunction with the above-mentioned illustrations.

[0049] Step S101, using the upper (left) half core box 101 and the lower (right) half core box 102 to form a complete core box 103, wherein the interface between the two is at the largest sand core profile. And set the live block in the necessary position.

[0050] After the sand core is formed, the core box 103 must be separated from the sand core, as long as the interface between the upper (left) half core box 101 and the right (lower) half core box 102 is set at the largest part of the sand core contour, it can be convenientl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com